Femtosecond laser mode adjustable optical tweezers control device based on column vector light beam

A femtosecond laser and manipulation device technology, applied in optics, optical components, microscopes, etc., can solve problems such as thermal damage, achieve damage-free manipulation, improve capturing power, and avoid thermal damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

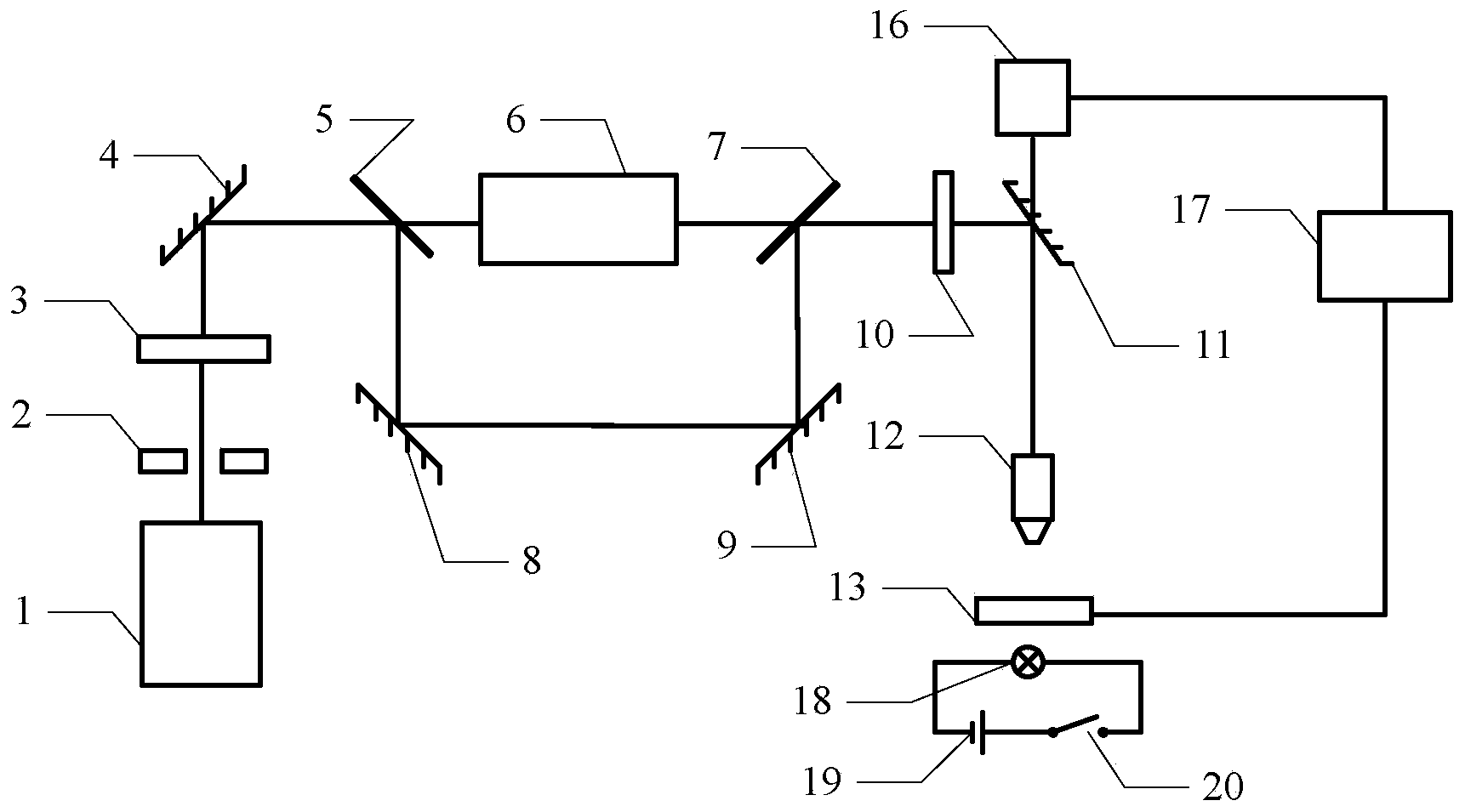

[0019] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment. The difference between the femtosecond laser mode adjustable optical tweezers control device based on the cylindrical vector beam described in this specific embodiment is that it includes a femtosecond pulsed laser 1, an aperture 2, an attenuation plate 3, The first 800nm total reflection mirror 4, the first beam splitter 5, the polarization converter 6, the second beam splitter 7, the second 800nm total reflection mirror 8, the third 800nm total reflection mirror 9, the shutter 10, the fourth 800nm total reflection mirror mirror 11, microscope 12 and stage 13,

[0020] The pulsed laser light emitted by the femtosecond pulse laser 1 enters the attenuation plate 3 through the diaphragm 2, and the attenuation plate 3 attenuates the light intensity of the pulsed laser light, and then the pulsed laser light is incident on the first 800nm total reflection mirror 4, and the first...

specific Embodiment approach 2

[0027] Embodiment 2. The difference between this embodiment and the femtosecond laser mode tunable optical tweezers control device based on cylindrical vector beam described in Embodiment 1 is that the femtosecond pulsed laser 1 is titanium-doped sapphire femto second laser with an output pulse repetition rate of 76 MHz and a pulse width of 120 femtoseconds.

specific Embodiment approach 3

[0028] Embodiment 3. The difference between this embodiment and the femtosecond laser mode tunable optical tweezers control device based on columnar vector beams described in Embodiment 1 is that the stage 13 is a three-dimensional micro-displacement platform.

[0029] The control accuracy of the three-dimensional linear excitation source of the stage 13 in this embodiment is 50 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com