System and method for detecting operation panel of sewing machine

A detection system and operation panel technology, applied in electrical testing/monitoring and other directions, can solve problems such as low detection efficiency, affect the accuracy of test results, and reduce test reliability, achieve time-saving and labor-saving reliability, and facilitate batch processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

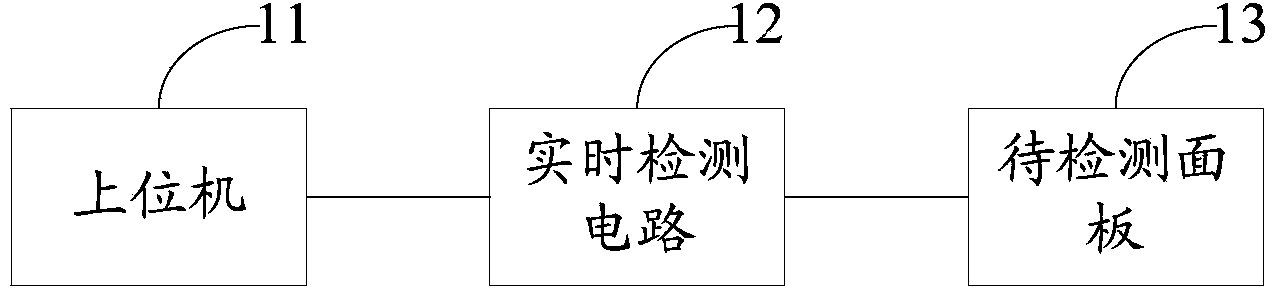

[0033] see figure 1 , figure 1 It is a schematic structural diagram of a detection system for a sewing machine operation panel disclosed in an embodiment of the present application.

[0034] like figure 1 As shown, the detection system includes:

[0035] Host computer 11, real-time detection circuit 12 and panel 13 to be detected, wherein,

[0036] After the real-time detection circuit 12 receives the detection instruction sent by the host computer 11, it sends test data to the panel 13 to be detected, and obtains the detection result fed back by the panel 13 to be detected, and sends the detection result to the Above-mentioned host computer 11.

[0037] The upper computer 11 communicates with the real-time detection circuit 12 through a bus connection, and the upper computer 11 transmits detection instructions to the real-time detection circuit to drive the real-time detection circuit 12 to execute the detection program, so as to realize reliable detection of the panel 13...

Embodiment 2

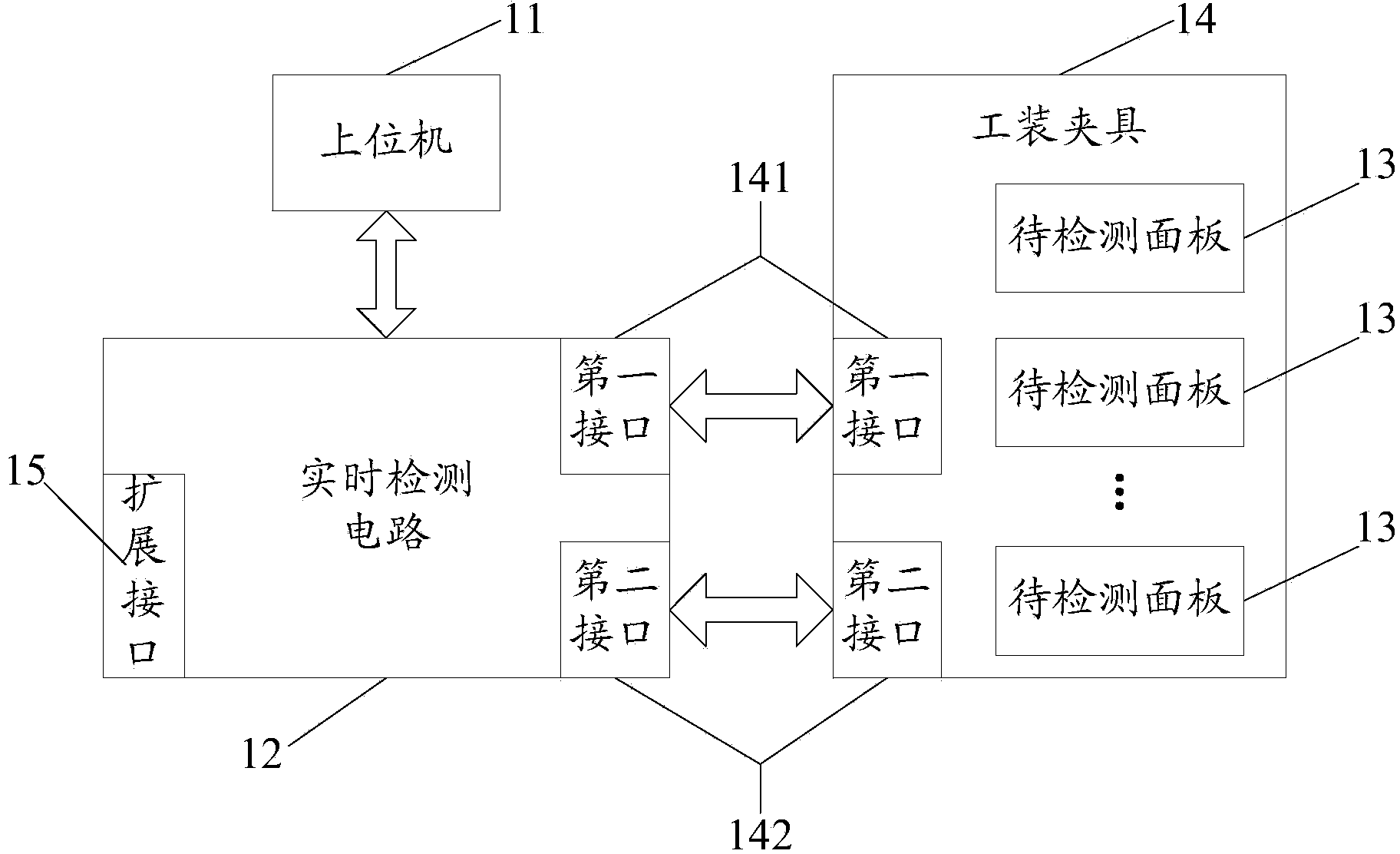

[0043] When there are multiple panels to be inspected, in order to facilitate inspection, we use the form of fixtures to install multiple panels to be inspected in one fixture. see figure 2 , figure 2 It is a structural schematic diagram of another detection system of the sewing machine operation panel disclosed in the embodiment of the present application.

[0044] like figure 2 Shown:

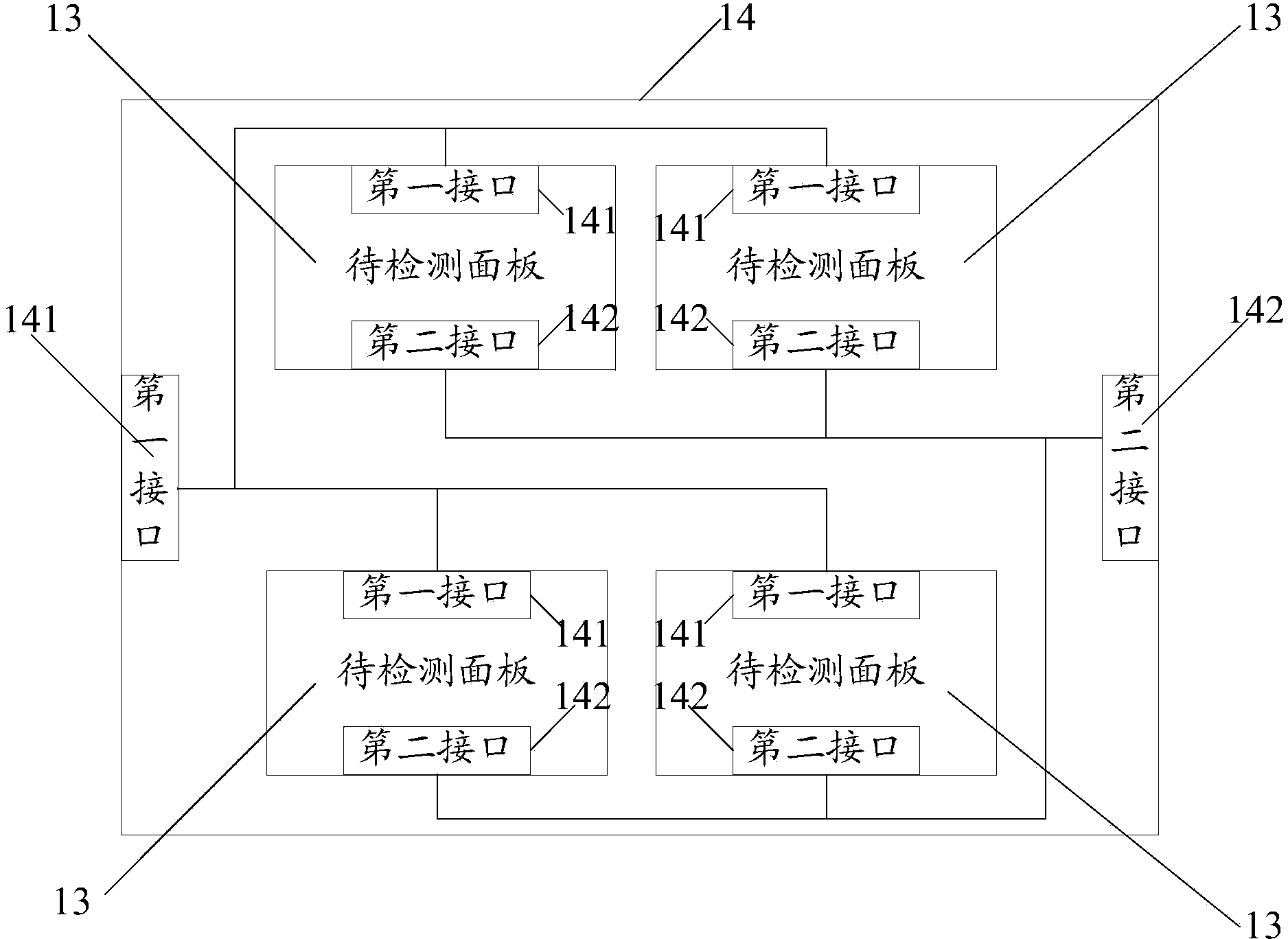

[0045] A plurality of panels 13 to be inspected are placed in the fixture 14 according to certain rules, and the fixture 14 is provided with a first interface 141 and a second interface 142, wherein the first interface 141 and the second interface 142 are respectively connected to each panel 13 to be inspected. connected, see image 3 ( image 3 Only the case of 4 panels to be tested is exemplified). Correspondingly, two interfaces are provided in the real-time detection circuit 12 , namely the first interface 141 and the second interface 142 . The real-time detection circuit 12 sen...

Embodiment 3

[0049] This embodiment discloses a detection method for an operation panel of a sewing machine, which is applied to the detection systems disclosed in the foregoing embodiments.

[0050] see Figure 4 , the detection method includes:

[0051] Step 401: Receive a detection instruction sent by the host computer;

[0052] Step 402: sending test data to the panel to be tested;

[0053] Step 403: Receive the detection result fed back by the panel to be detected;

[0054] Step 404: Send the detection result to the host computer.

[0055] In the detection method of the sewing machine operation panel disclosed in this application, after the real-time detection circuit receives the detection instruction sent by the host computer, the test data is sent to the panel to be detected, and the detection result fed back by the panel to be detected is received, and the real-time detection circuit sends the detection result to the host computer. During the entire detection process, the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com