Novel method for manual viscosity control

A manual control and new method technology, applied in the direction of viscosity control, non-electric variable control, control/adjustment system, etc., can solve the problem of high equipment investment cost and later equipment maintenance cost, the influence of the accuracy of viscosity correction value, and the difficulty of vibrating viscometer In case of failure and other problems, the effect of improving control stability, simple installation and convenient operation is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

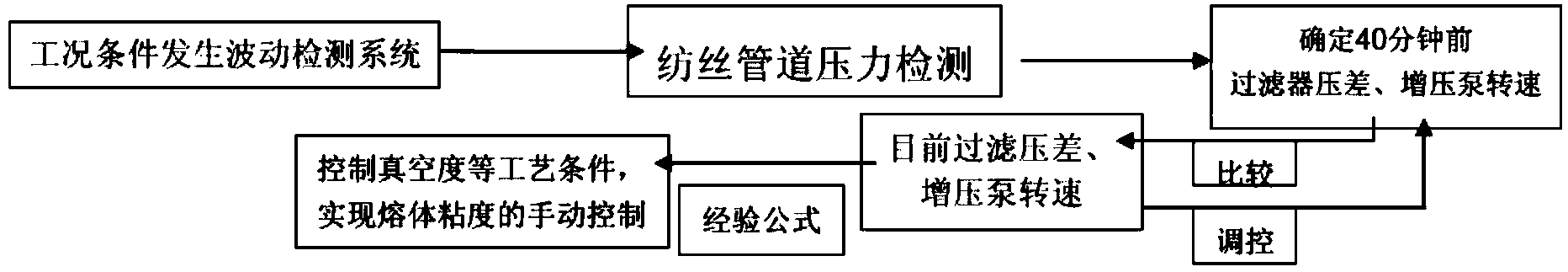

[0023] A new method for manual viscosity control is used to guide melt viscosity control when production conditions change. Such as figure 1 The specific control process shown includes: the production condition fluctuation detection system finds abnormal production conditions → the spinning pipeline pressure detection system detects the melt pressure in the pipeline → calculates the filter pressure difference and booster pump speed 40 minutes ago → Convert the melt viscosity drop through the pressure conversion formula 1 and the correction formula 2 of the actual viscosity change → use the converted melt viscosity drop as a production guide to adjust the vacuum degree and other process conditions → realize manual control of the melt viscosity.

[0024] The specific operation method is:

[0025] (1) When the production condition fluctuates, pass the formula 1 through the spinning pipeline pressure detection system:

[0026] P=ΔPr+Pg+ΔPf

[0027] Infer the filter pressure dif...

Embodiment 2

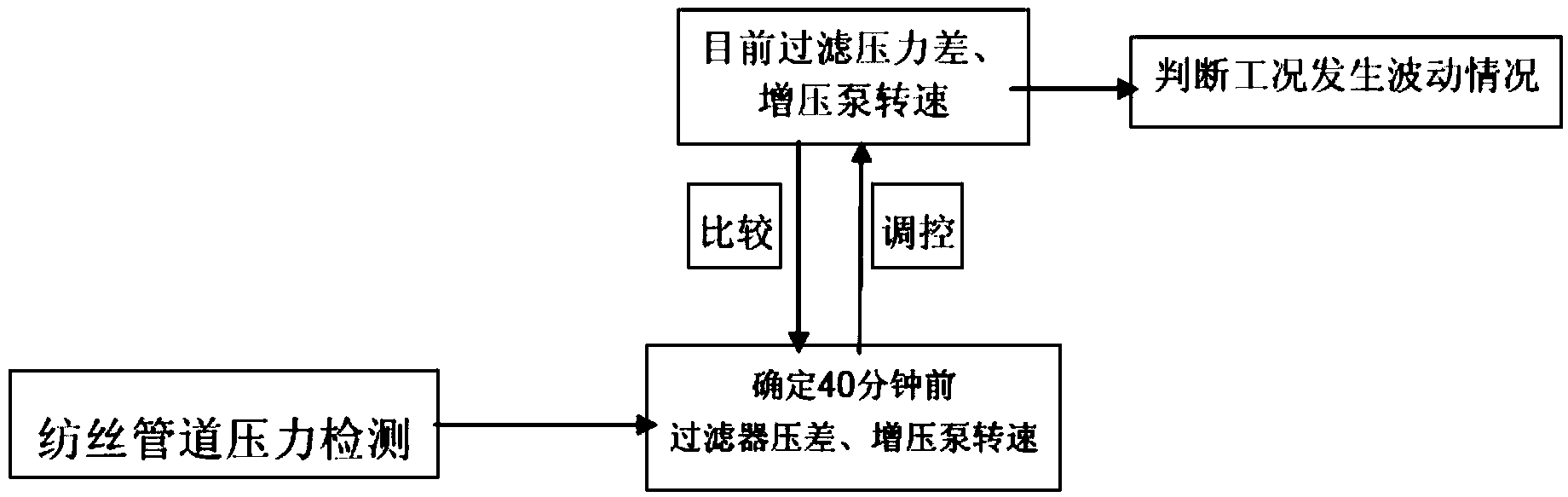

[0033] A new method for manual viscosity control, used in judging changes in production conditions. Such as figure 2 The specific control process shown includes: the spinning pipeline pressure detection system measures the melt pressure in the pipeline → calculates the filter pressure difference and booster pump speed 40 minutes ago and compares it with the current filter pressure difference and booster pump speed → Judging changes in production conditions.

[0034] The specific operation method is:

[0035] (1) The pressure difference of the filter and the speed of the booster pump 40 minutes ago can be calculated by measuring the melt pressure in the pipeline through the pressure detection system of the spinning pipeline.

[0036] (2) Compare the differential pressure of the filter and the rotational speed of the booster pump 40 minutes ago calculated through step (1) with the differential pressure of the filter and the rotational speed of the booster pump at present.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com