Poly-phase alternating-current linear motor system for ring windings

A technology of ring winding and linear motors, which is applied in the direction of propulsion systems, electrical components, electromechanical devices, etc., and can solve the problem of large harmonic components of the magnetomotive force and electromotive force of the winding, large transverse support span of the mover, and difficult support of the mover. problem, to achieve the effect of low manufacturing cost, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

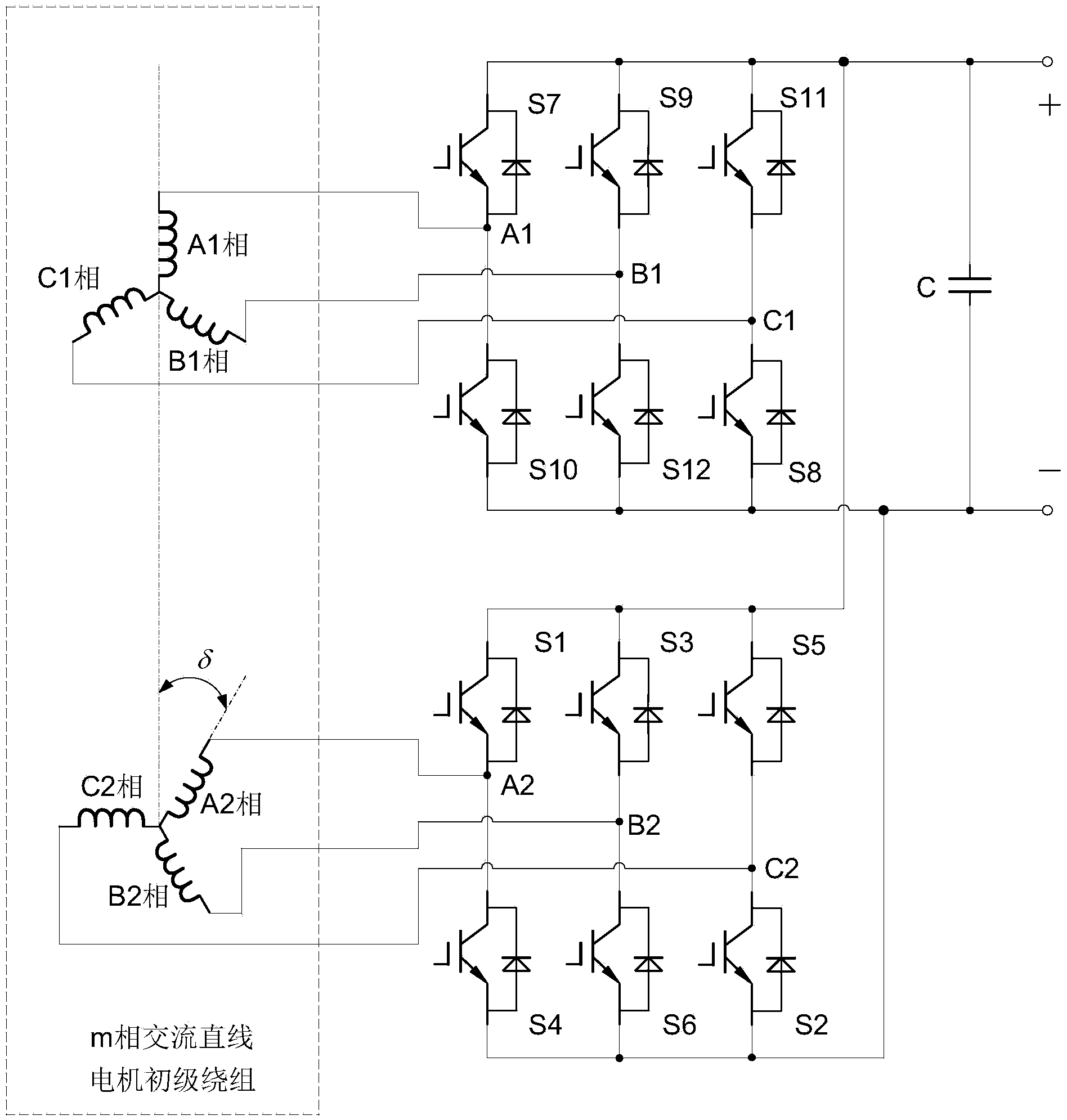

[0025] Specific implementation mode 1: the following combination figure 1 To explain this embodiment, the toroidal winding multi-phase AC linear motor system of this embodiment includes m-phase AC linear motor and m / 3 three-phase power converters; m=3k, and k is a positive integer greater than 1;

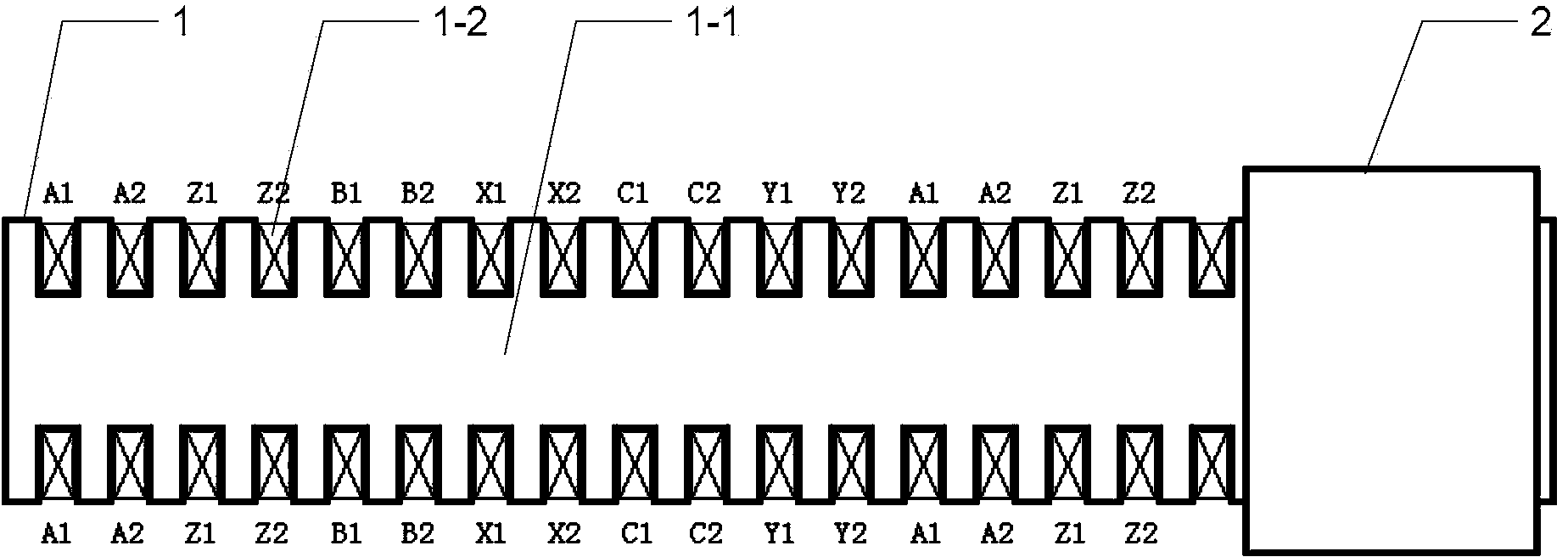

[0026] The m-phase AC linear motor includes a primary 1 and a secondary 2;

[0027] The primary 1 includes a primary core 1-1 and m / 3 sets of primary toroidal windings 1-2. The primary toroidal windings 1-2 are three-phase toroidal windings; every two adjacent primary toroidal windings 1-2 correspond to phases between The electrical angle phase difference is δ, and meets the condition δ=±180° / m; the three lead wires of each set of primary toroidal winding 1-2 are connected to the three AC output terminals of a three-phase power converter in a one-to-one correspondence;

[0028] m / 3 three-phase power converters share the DC bus, and the electrical angle phase difference of the correspondin...

specific Embodiment approach 2

[0031] Specific implementation manner 2: the following combination Image 6 To describe this embodiment, the toroidal winding multi-phase AC linear motor system of this embodiment includes an m-phase AC linear motor and an m-phase power converter; m is a positive integer greater than or equal to 5;

[0032] The m-phase AC linear motor includes a primary 1 and a secondary 2;

[0033] The primary 1 includes a primary core 1-1 and a primary toroidal winding 1-2. The primary toroidal winding 1-2 is an m-phase toroidal winding; the electrical angle phase difference between each two adjacent phases of the primary toroidal winding 1-2 is δ , And satisfy the condition δ=±360° / m; the lead wire of each phase of the primary toroidal winding 1-2 is connected to an AC output terminal of the m-phase power converter;

[0034] The m-phase power converter outputs m-phase current, and the electrical angle phase difference between each adjacent two-phase current is δ.

[0035] To Image 6 Given m=5 as a...

specific Embodiment approach 3

[0036] Specific implementation manner three: the following combination figure 2 , image 3 with Figure 7 To explain this embodiment, this embodiment will further explain the first or second embodiment, the secondary 2 is a bilateral structure, and there is an air gap between the primary 1 and the secondary 2;

[0037] The cross section of the primary core 1-1 is rectangular, and the left and right air gap sides of the primary core 1-1 are slotted symmetrically along the direction of movement, and the slots are evenly distributed along the direction of movement; the primary toroidal winding 1-2 is The toroidal winding, the coil constituting the primary toroidal winding 1-2 is rectangular, and a coil is embedded in two slots corresponding to the left and right positions of the primary core 1-1.

[0038] The two effective sides of each coil are embedded in the two corresponding, symmetrical slots on the left and right of the primary core 1-1. Only one coil side is embedded in each sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com