Composite cloth sheet for decoration

A technology of composite cloth and cloth sheet, which is used in the decoration, transportation and packaging of textiles, synthetic resin layered products, etc. Beautiful design, improved adhesion, and high-grade effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

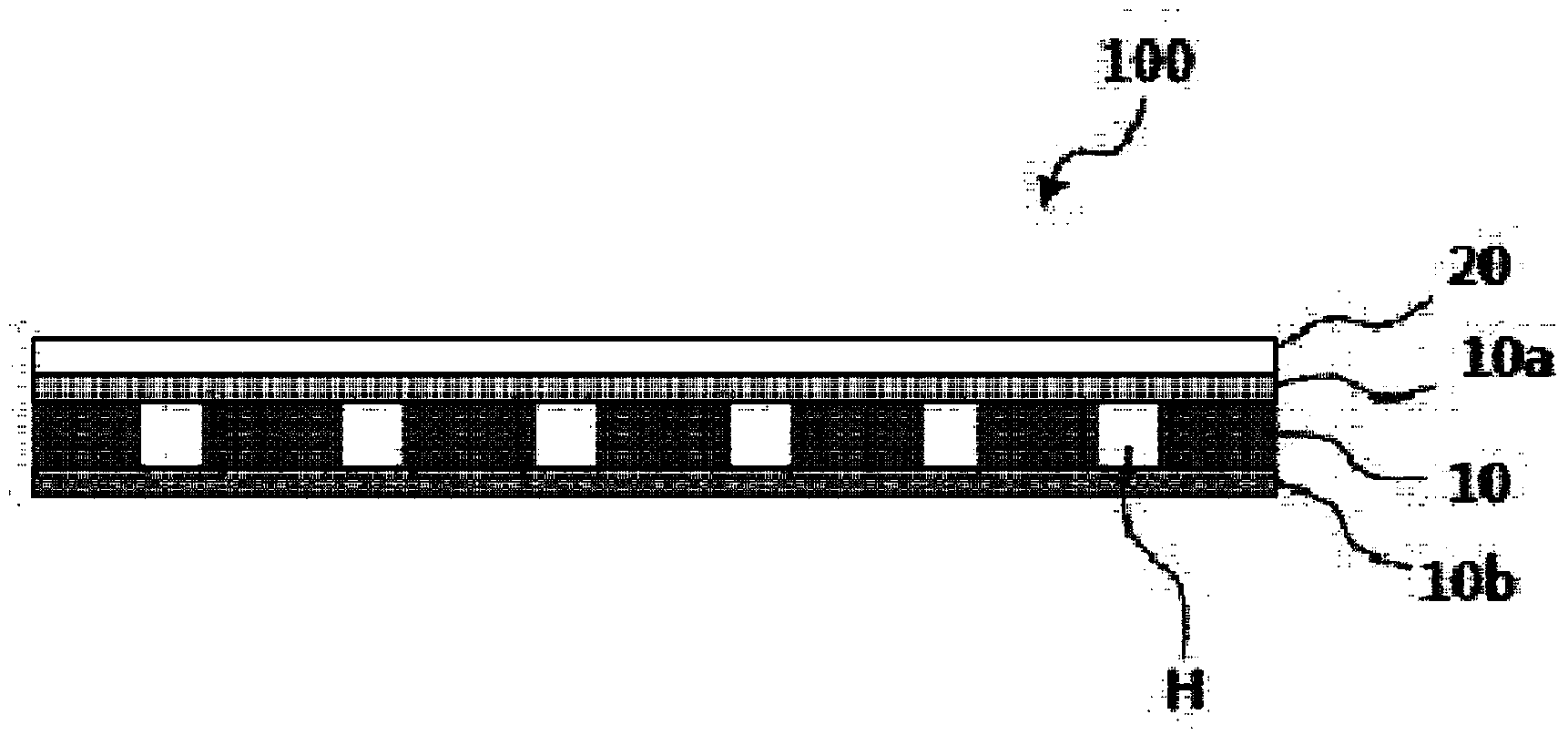

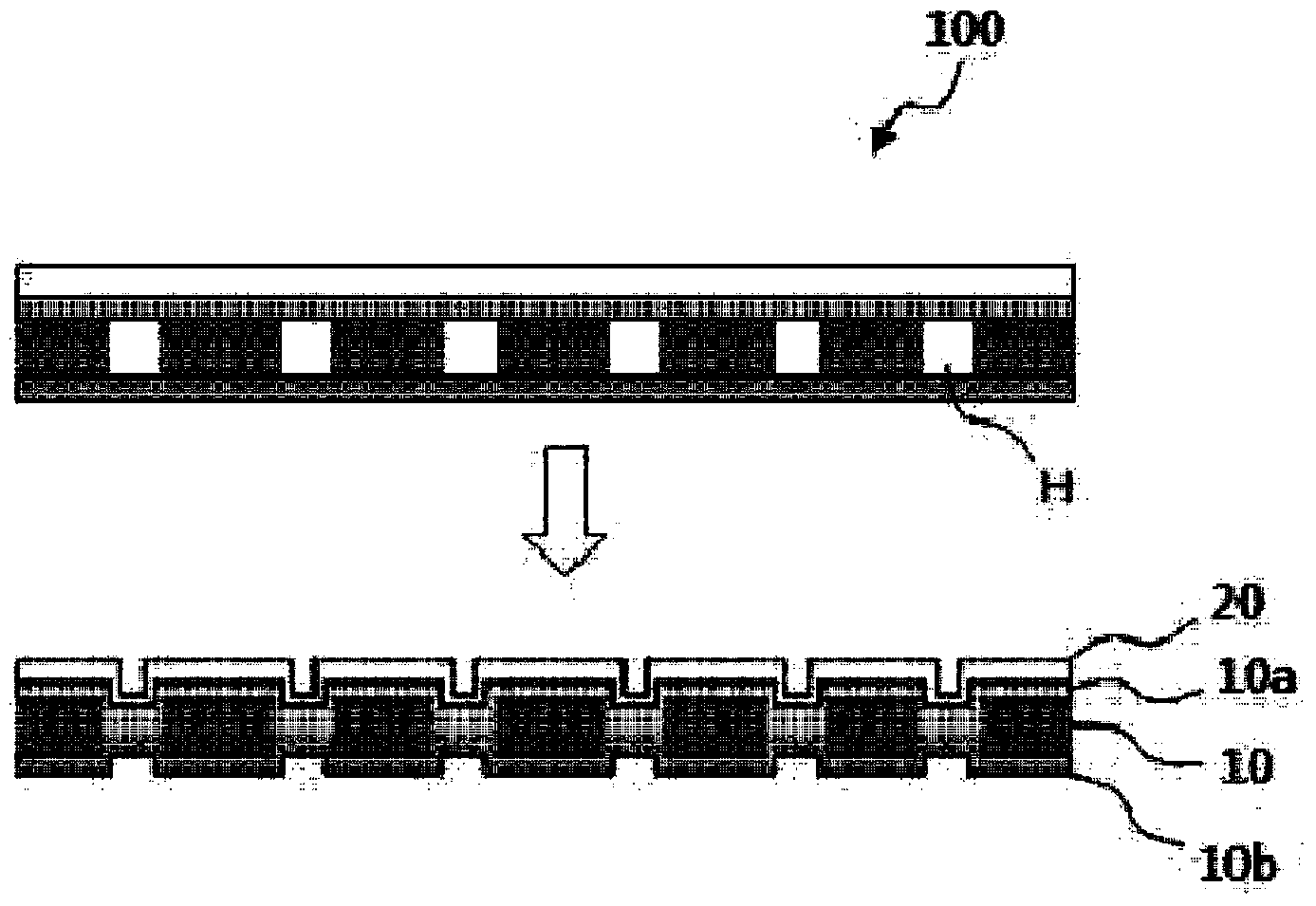

[0043] A first hot-melt adhesive film layer is formed between the fabric layer made of net and the film layer made of TPU, and after the second hot-melt adhesive film layer is formed under the fabric layer, heat press (heat press) is used to At a temperature of 140°C and a pressure of 50kg / cm 2 Under the condition of pressing for 25 seconds, the composite cloth for decoration was manufactured.

[0044] At this time, the thickness of the film layer is 200 μm, the thickness of the first hot melt adhesive film layer is 30 μm, and the thickness of the second hot melt adhesive film layer is 150 μm.

Embodiment 2

[0046] A first hot-melt adhesive film layer is formed between the fabric layer made of net and the film layer made of TPU, and after the second hot-melt adhesive film layer is formed under the fabric layer, heat press (heat press) is used to At a temperature of 140°C and a pressure of 50kg / cm 2 Under the condition of pressing for 25 seconds, the composite cloth for decoration was manufactured.

[0047] At this time, the thickness of the thin film layer is 200 μm, the thickness of the first hot melt adhesive film layer is 50 μm, and the thickness of the second hot melt adhesive film layer is 150 μm.

Embodiment 3

[0049] A first hot-melt adhesive film layer is formed between the fabric layer made of net and the film layer made of TPU, and after the second hot-melt adhesive film layer is formed under the fabric layer, heat press (heat press) is used to At a temperature of 140°C and a pressure of 50kg / cm 2 Under the condition of pressing for 25 seconds, the composite cloth for decoration was manufactured.

[0050] At this time, the thickness of the film layer is 300 μm, the thickness of the first hot melt adhesive film layer is 30 μm, and the thickness of the second hot melt adhesive film layer is 200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com