Functional flavoring agent for feed and preparation method of functional flavoring agent

A functional and flavoring agent technology, applied in animal feed, animal feed, application, etc., can solve the problems of unsatisfactory effect and single type of flavoring agent, and achieve the function of protecting the stomach, improving intestinal function, and improving flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

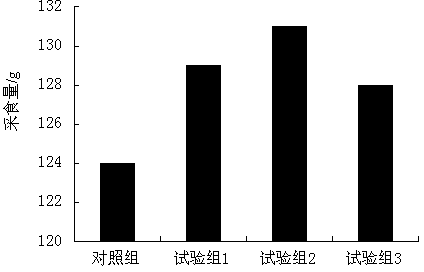

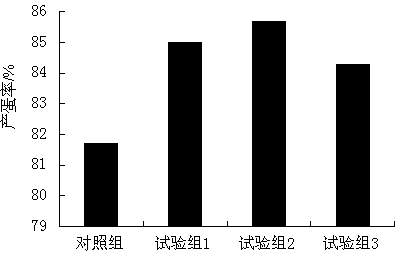

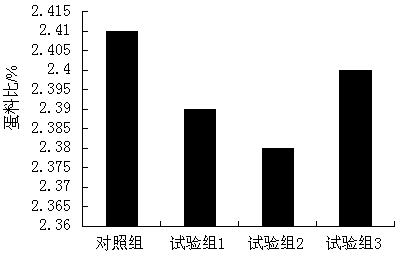

Embodiment 1

[0021] Each raw material is automatically weighed by the electronic weighing system according to the weight ratio. The raw material ratio is as follows: (1) 5kg of glutamine raw material per 100kg; (2) 8kg of disodium 5'-guanylate; (3) Disodium 5'-inosinate 8kg; (4) γ-aminobutyric acid raw material 6kg; (5) stevia extract 5kg; (6) carboxymethyl chitosan 1.2kg; (7) iron glycinate raw material 0.1kg (8) 66.7kg of corn flour. Add the weighed raw materials into the mixer by the material conveying system and mix for 5 minutes to make the uniformity reach 5%; pack the prepared powder to obtain the finished product. The particle size of the finished product is capable of passing through a 16-mesh sieve, and the coefficient of variation is 6.5%.

Embodiment 2

[0023] Each raw material is automatically weighed by the electronic weighing system according to the weight ratio. The raw material ratio is as follows: (1) 6kg of glutamine raw material per 100kg; (2) 9kg of disodium 5'-guanylate; (3) 9kg of disodium 5'-inosinate; (4) 5kg of gamma-aminobutyric acid raw material; (5) 6kg of stevia extract; (6) 2kg of carboxymethyl chitosan; (7) 0.15kg of iron glycinate raw material; (8) 62.85kg of corn flour. Add the weighed raw materials into the mixer by the material conveying system and mix for 8 minutes to make the uniformity reach 5%; pack the prepared powder to obtain the finished product. The particle size of the finished product is capable of passing through a 16-mesh sieve, and the coefficient of variation is 6.6%.

Embodiment 3

[0025] Each raw material is automatically weighed by the electronic weighing system according to the weight ratio. The raw material ratio is as follows: (1) 8kg of glutamine raw material per 100kg; (2) 7kg of disodium 5'-guanylate; (3) 5'-inosinic acid disodium 7kg; (4) gamma-aminobutyric acid raw material 8kg; (5) stevia extract 7kg; (6) carboxymethyl chitosan 3kg; (7) iron glycinate raw material 0.2kg; (8) 59.8kg of corn flour. Add the weighed raw materials into the mixer by the material conveying system and mix for 10 minutes to make the uniformity reach 5%; pack the prepared powder to obtain the finished product. The particle size of the finished product is capable of passing through a 16-mesh sieve, and the coefficient of variation is 6.8%.

[0026] Glutamine, 5'-disodium guanylate 8kg, 5'-disodium inosinate, γ-aminobutyric acid, stevia extract, carboxymethyl chitosan, iron glycinate, Corn flour all adopts commercially available general products. Among them, the glutam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com