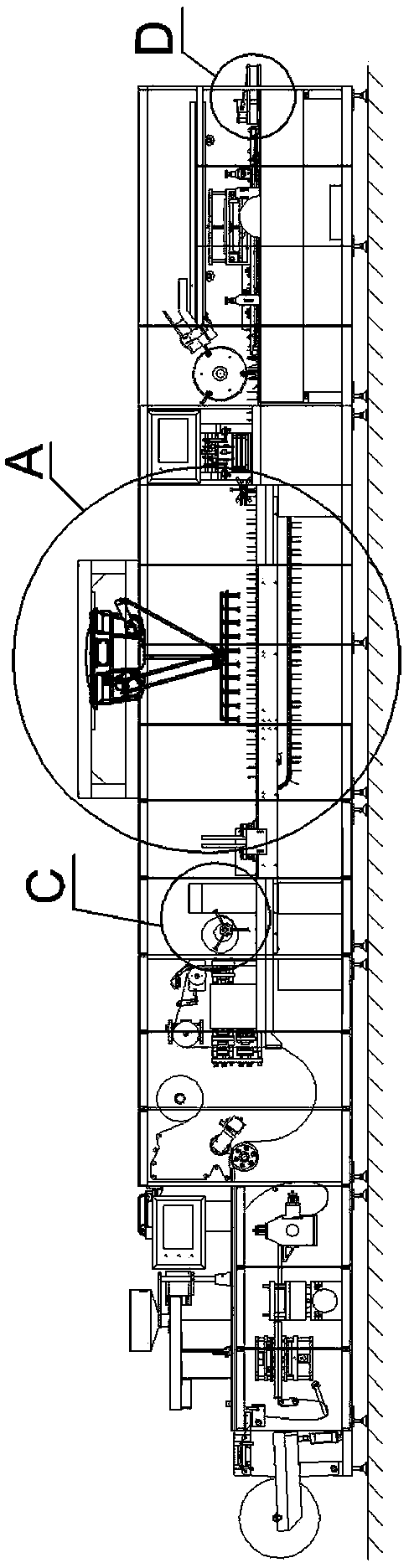

Bubble cap boxing machine

A cartoning machine and blister technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of long assembly line, affecting the efficiency of cartoning, and inability to realize production, so as to achieve the effect of improving production efficiency and shortening the length of the assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

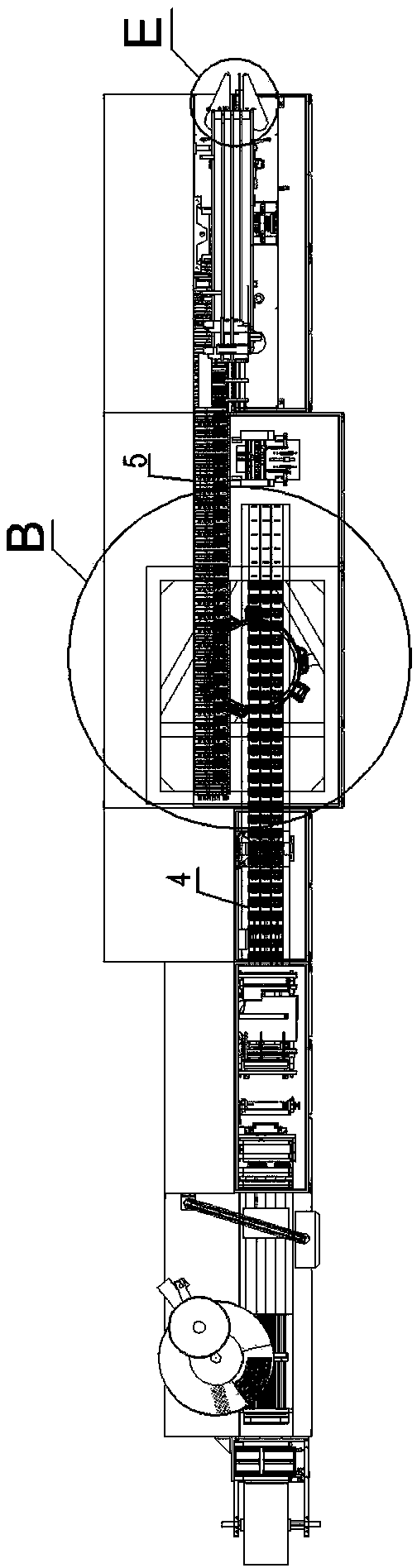

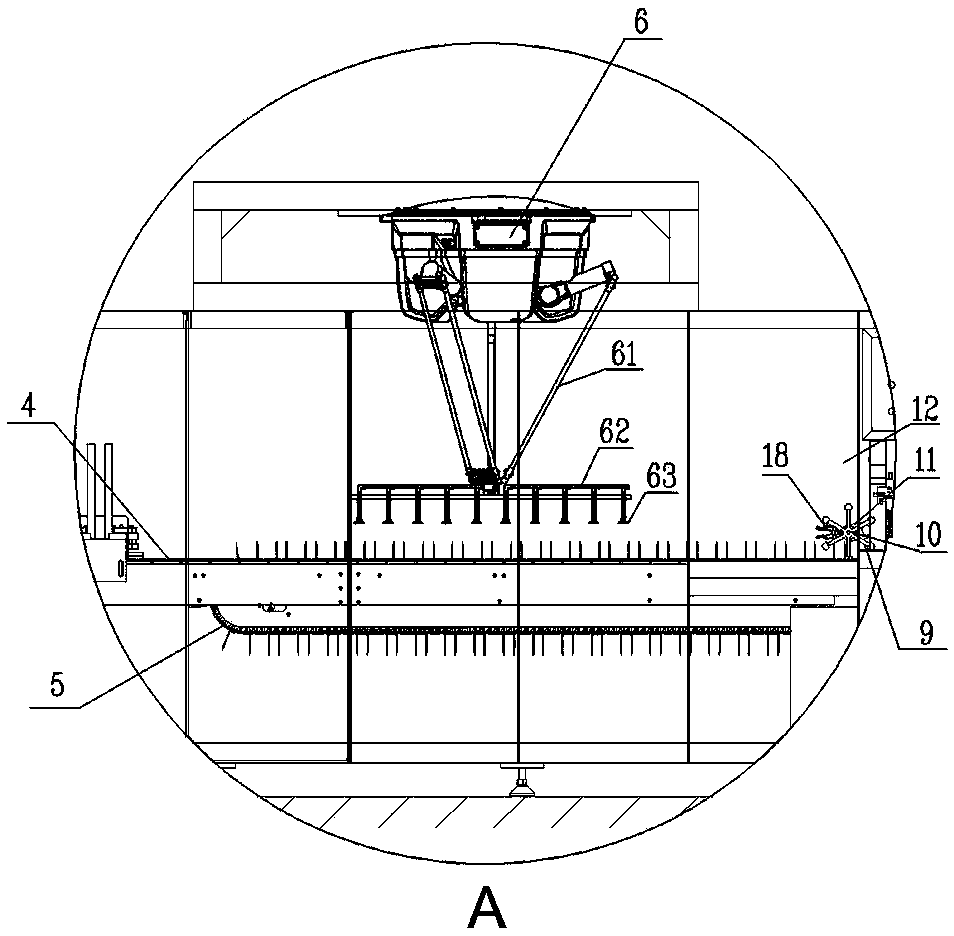

[0017] The manipulator 6 moves, and the blister plate 7 on the push plate conveying mechanism is transferred to the feed bin conveying mechanism, and then the blister plate 7 and the instructions are packed into the medicine box through multiple procedures. The push plate conveying mechanism includes an assembly line type push plate grid 4 that is continuously conveyed, and each unit of the push plate grid 4 can store a blister plate. In order to improve production efficiency, the push plate grid 4 can be provided with multiple channels, each of which is a transport path for a blister plate 7, and the present invention specifically provides three channels. On one side of the push plate conveying mechanism, that is, a silo conveying mechanism is arranged at a position side by side with the push plate conveying mechanism. Unit can store a single plate or a stack of blister plates. Since the manipulator 6 transfers the rated number of blister plates 7 together into the bin grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com