A kind of water-soluble ceramic ink

A ceramic ink, water-soluble technology, applied in inks, household appliances, applications, etc., can solve the problem that organic dyes and low-temperature pigments are not suitable for ceramic inks, and achieve the effect of stable color, good stability and not easy precipitation

Inactive Publication Date: 2016-04-27

MINJIANG UNIV

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Ceramic products generally need to be fired at a high temperature of more than 1,000 degrees, and the ink that is compatible with it also needs to withstand this temperature, so organic dyes and low-temperature pigments are not suitable for ceramic inks

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Login to View More

Abstract

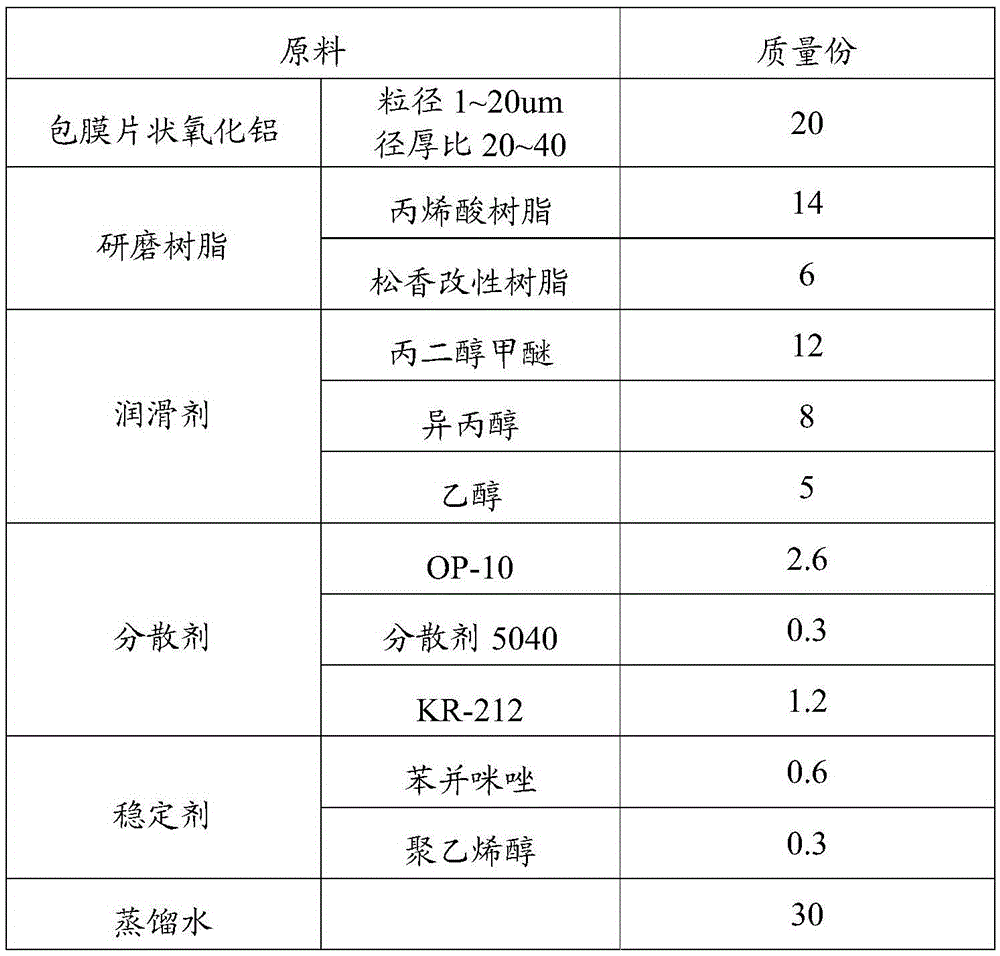

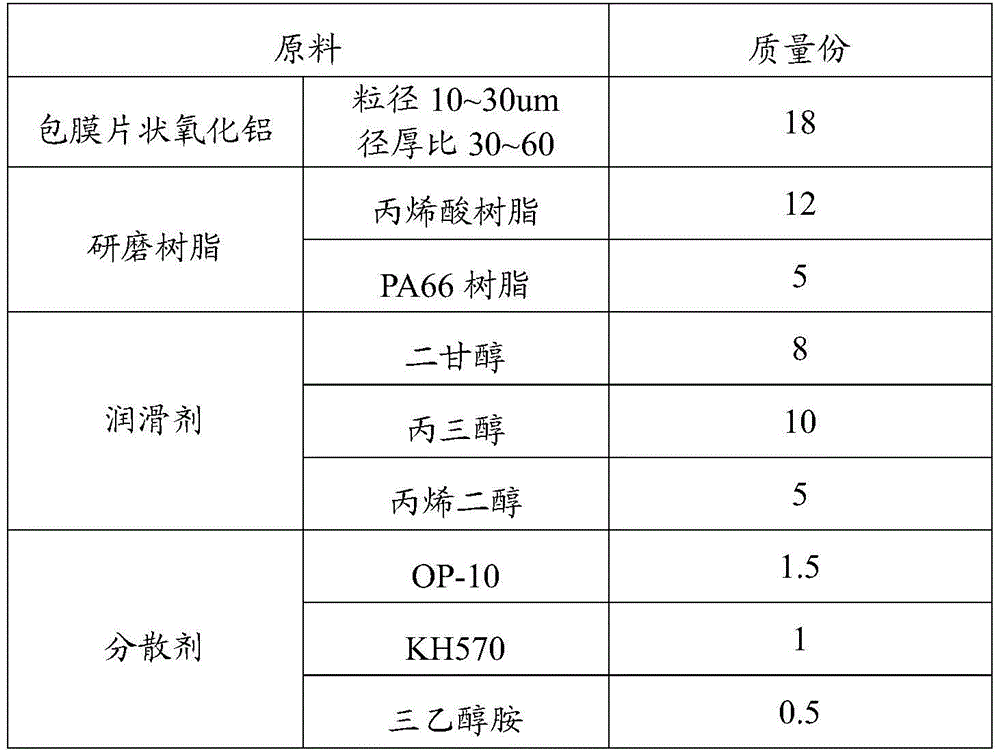

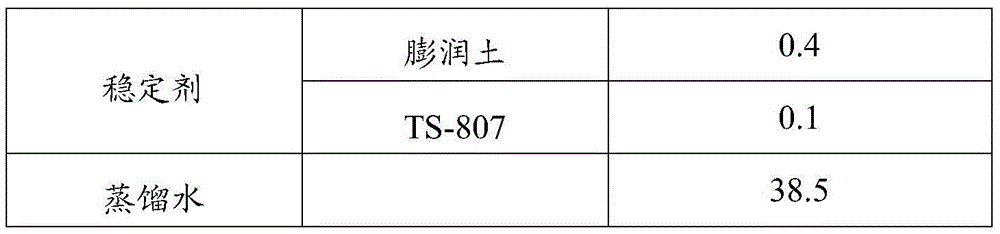

The invention discloses water-soluble ceramic ink which comprises the following raw materials in parts by weight: 8-25 parts of flaky alumina, 5-20 parts of grinding resin, 7-25 parts of a lubricant, 0.7-5 parts of a dispersant, 0.5-3 parts of a stabilizer and 30-75 parts of distilled water. A preparation method of the ceramic ink comprises the following steps: mixing flaky alumina, the dispersant and 60% of the distilled water, and quickly stirring to be uniform by using a stirring machine; adding the lubricant, quickly stirring for 15 minutes, adding the grinding resin while stirring at the low speed, and continuously stirring for 30 minutes; finally adding the stabilizer and the residual distilled water, stirring for 30 minutes to obtain slurry, feeding the slurry into a ball mill for performing ball-milling until the particle size of the slurry is 50nm to 900nm, or feeding the slurry into a high-pressure homogenizing machine for homogenizing until the particle size of the slurry is 50nm to 900nm. The ceramic ink is good in high temperature resistance, high in chromogenic rate, stable in color, unlikely to deposit and good in stability.

Description

technical field [0001] The invention relates to a water-soluble ceramic ink. Background technique [0002] With the rapid development of computer printing technology, digital technology has also been applied in the traditional ceramic industry. In the field of ceramic decoration, it has also transitioned from lithographic printing to rubber roller printing, and even the latest inkjet printing technology. Inkjet printing technology is a decoration technology with great potential. Through the digital control of the computer, the ink is sprayed to the surface of the body or glaze through the nozzles on the print head to form the desired pattern, which can be a single color or a combination of multiple colors. [0003] Ceramic products generally need to be fired at a high temperature of more than 1,000 degrees, and the ink that is compatible with it also needs to withstand this temperature, so organic dyes and low-temperature pigments are not suitable for ceramic inks. Most of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D11/30

Inventor 吴华忠杨春蓉陈为健黄杏芳

Owner MINJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com