Tissue control method for near-eutectic cast aluminum-silicon alloy

A technology of casting aluminum-silicon alloy and control method, which is applied in the field of structure control of near-eutectic aluminum-silicon alloy, can solve the problems of being difficult to apply to actual production and high price, and achieve the effects of cheap price, improved comprehensive performance and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The cast aluminum-silicon alloy was prepared according to the above steps. In step 1), the composition mass percentage was set as Si: 11%, and the rest was Al. In step 3), lanthanum is selected as the rare earth and added in the form of master alloy Al-10La, and the mass percentages of B and La are 0.03%-0.05% and 0.05%-0.1% respectively. like image 3 As shown, the cast Al-11Si alloy prepared by joint refinement of boron and rare earth lanthanum was obtained. Obtain equiaxed primary aluminum with an average size of 40-50 microns, and at the same time, the modification effect of eutectic silicon is equivalent, which can be seen Figure 4 .

Embodiment 2

[0037] The cast aluminum-silicon alloy was prepared according to the above steps. In step 1), the composition mass percentage was set as Si: 11%, and the rest was Al. In step 3), cerium is selected as the rare earth and added in the form of master alloy Al-10Ce, and the mass percentages of B and Ce are 0.03%-0.05% and 0.05%-0.15% respectively. like Figure 5 As shown, the cast Al-11Si alloy prepared by joint refinement of boron and rare earth cerium was obtained. Obtain equiaxed primary aluminum with an average size of 35-45 microns, and the eutectic silicon modification effect is equivalent, it can be seen Image 6 .

Embodiment 3

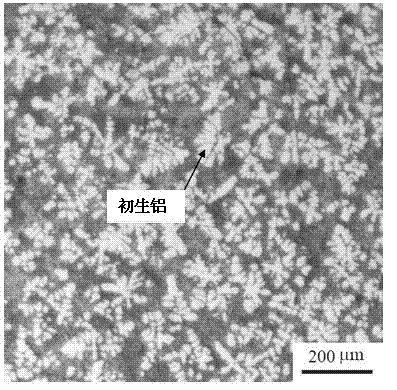

[0039]The cast aluminum-silicon alloy was prepared according to the above steps. In step 1), the composition mass percentage was set as Si: 11%, and the rest was Al. The rare earth in step 3) is mixed rare earth, which is added in the form of master alloy Al-10Re, and the mass percentages of B and Re are 0.03%-0.05% and 0.08%0.12% respectively. like Figure 7 As shown, the cast Al-11Si alloy prepared by joint refinement of boron and mixed rare earth was obtained. Obtain equiaxed primary aluminum with an average size of 30-40 microns, and the modification effect of eutectic silicon is equivalent, which can be seen Figure 8 .

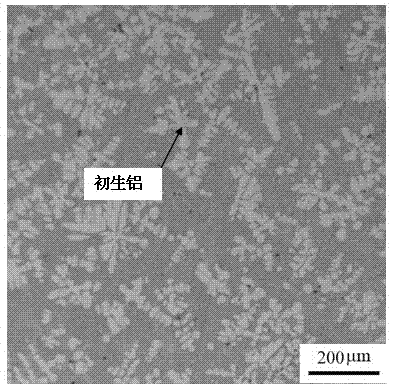

[0040] refer to figure 1 Low-magnification metallographic photograph of Al-11Si with boron added and no rare earth added. In the photo, the white is coarse and developed primary aluminum, and the black is fibrous eutectic silicon.

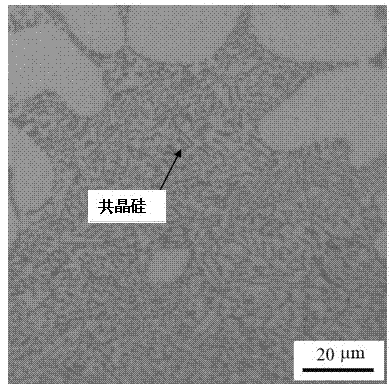

[0041] refer to figure 2 The high-magnification metallographic photograph of Al-11Si with boron added and no rare ear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com