Method for determining pile foundation bearing capacity after pile slipping

A bearing capacity and pile foundation technology, which is applied to the determination of the bearing capacity of the pile foundation, can solve the problem that the influence of sliding piles cannot be ignored, and achieve the effects of reducing manpower, easy and reliable parameters to be determined, and accurate calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0055] A method for determining the bearing capacity of a pile foundation after sliding piles, using the following steps:

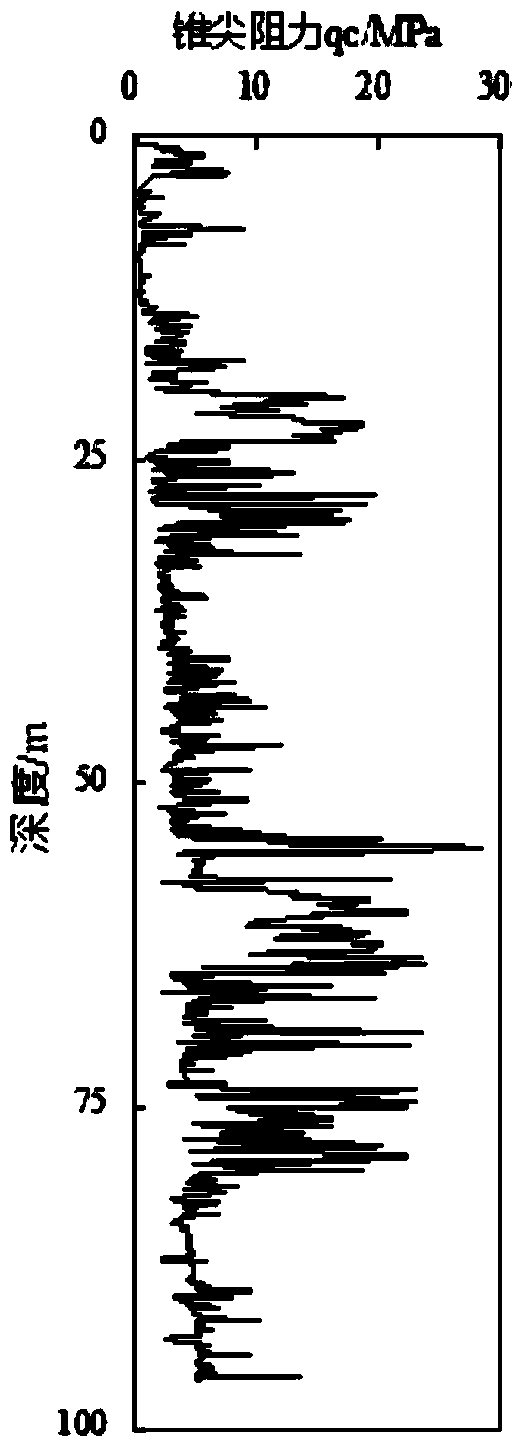

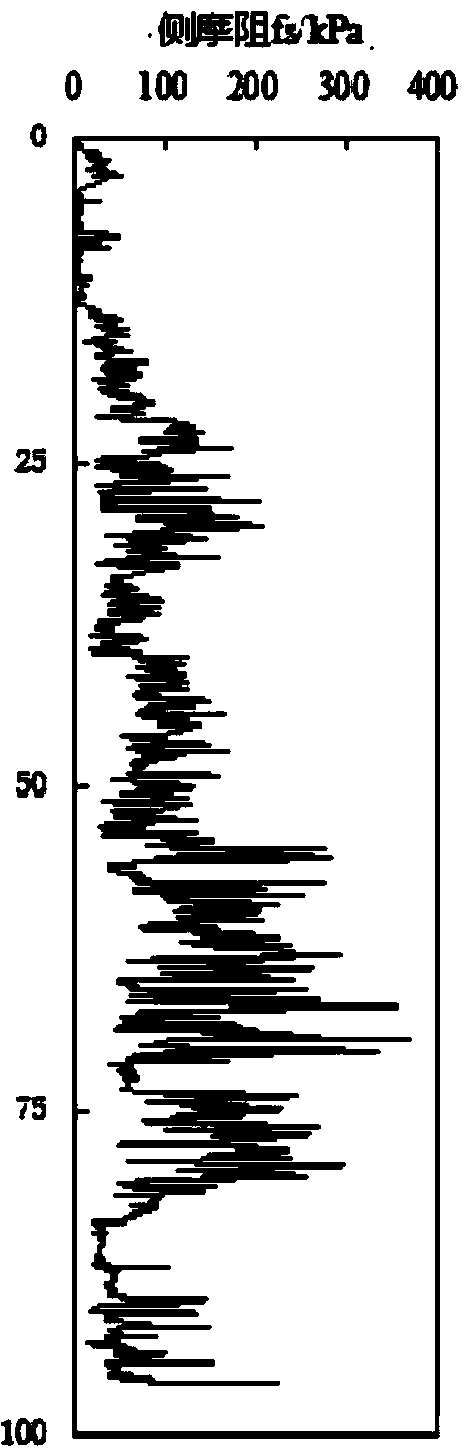

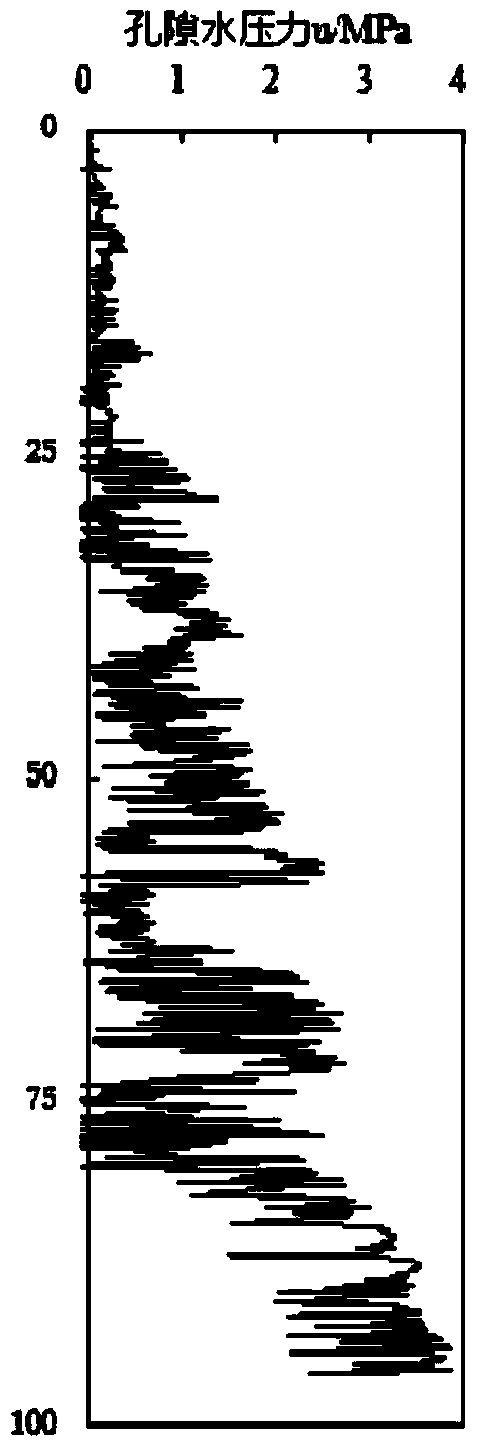

[0056] 1) Conduct static penetrating penetration test in situ to obtain the initial probe tip resistance q c ′, side friction resistance f s and the pore water pressure u;

[0057] When conducting CPT in-situ testing, the instrument and equipment used is the Wison-APB pile hole CPT system of the survey center. CPT probe cone angle is 60°, cone head area is 10cm 2 , the friction sleeve area is 150cm 2 . The pore pressure sensor is installed 5mm above the shoulder of the probe cone tip, the continuous penetration stroke of each test is 3m, and the penetration speed is 20mm / s. And before each CPT operation, the CPT pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com