A Giant Steel Support and Its Method of Interval Connection of Ribs

A steel support and rib technology, which is applied in the field of giant steel supports, can solve problems such as inconvenient welding and assembly of supports, and achieve the effects of solving inconvenient assembly, speeding up construction and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

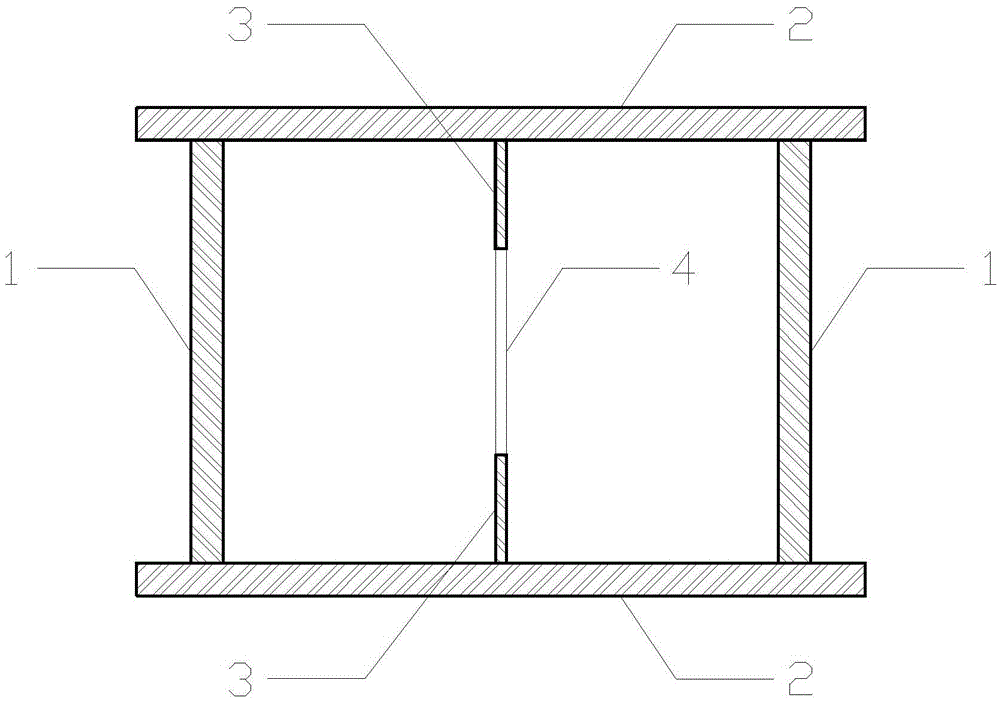

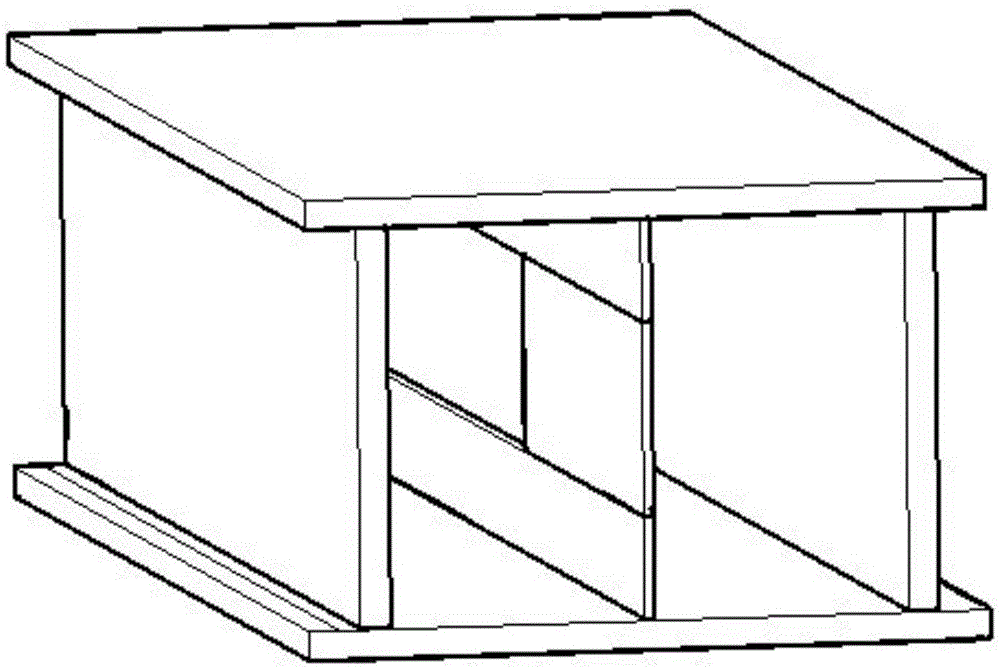

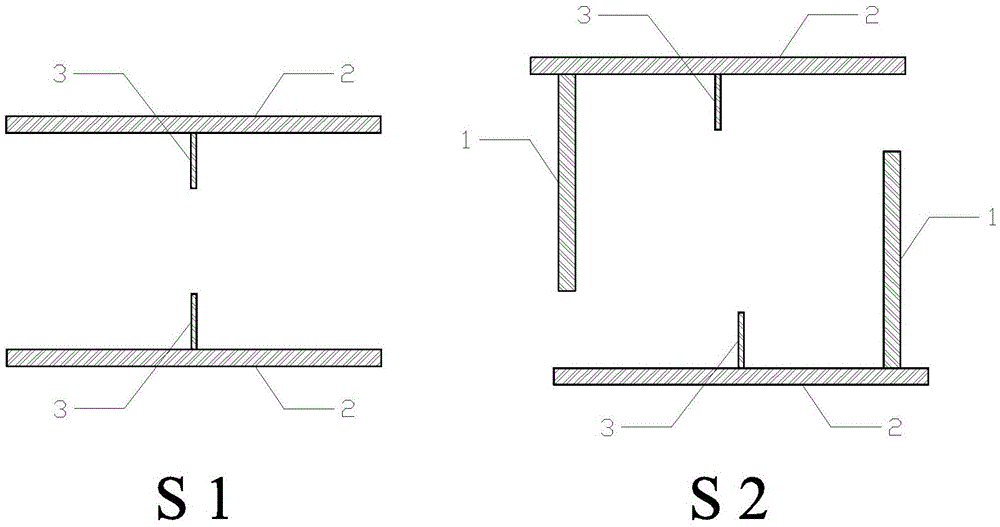

[0020] like Figure 1-4 , a giant steel support with spaced connection of ribs and its method, the giant steel support with spaced connection of ribs includes a flange 1, a web 2, a rib 3, a rib connecting member 4; two webs 2 mutually Parallel, the two ribs 3 are set on the vertical line of the web 2 and are located on the same plane, and are welded with each web 2 respectively, leaving a gap between the two ribs 3; after the ribs 3 and the web 2 are welded, The web 2 is then welded to the flange 1, and the flange 1 is welded to both ends of the rib 3, and the two flanges 1 and the web 2 are assembled and welded together to form a box-shaped section; the gap left by the two ribs 3 Finally, the rib plate connection member 4 is welded; all the members form a giant steel support with rib plate spaced connection through the above connection, and its cross secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com