Roller cone bit, tooling for installing roller cone bit retaining ring and installation method of retaining ring

A technology of roller cone bit and retaining ring, which is used in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of reducing the force area of the tooth palm shaft, affecting the service life of the drill bit, and large diameter of the locking steel ball, and achieves heat treatment. The effect is good, the processing effect is good, and the effect of increasing the bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

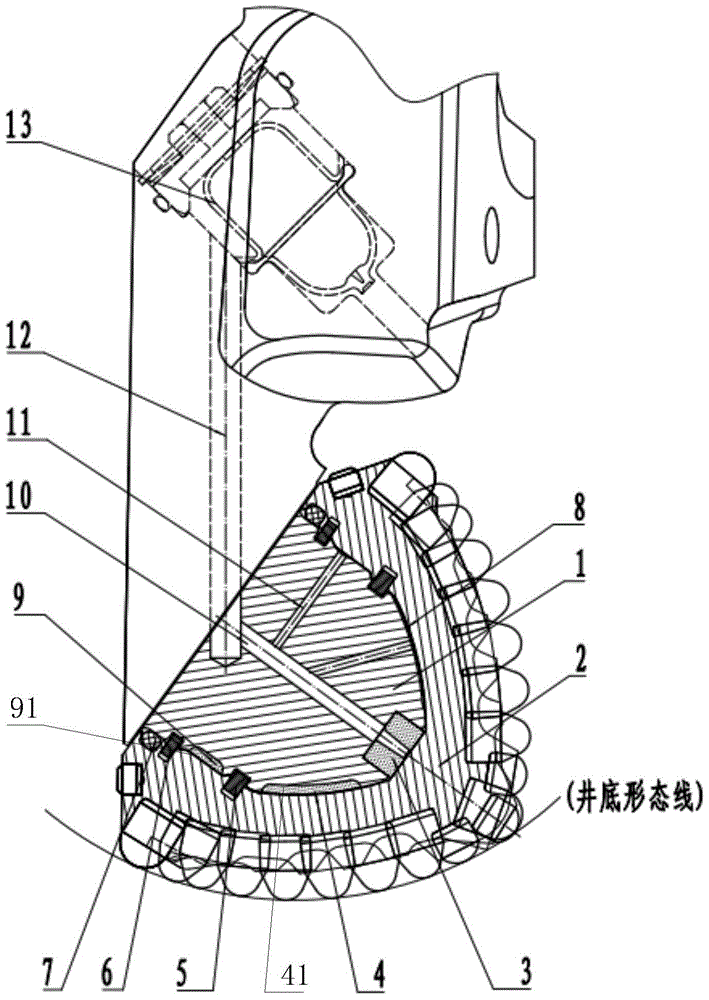

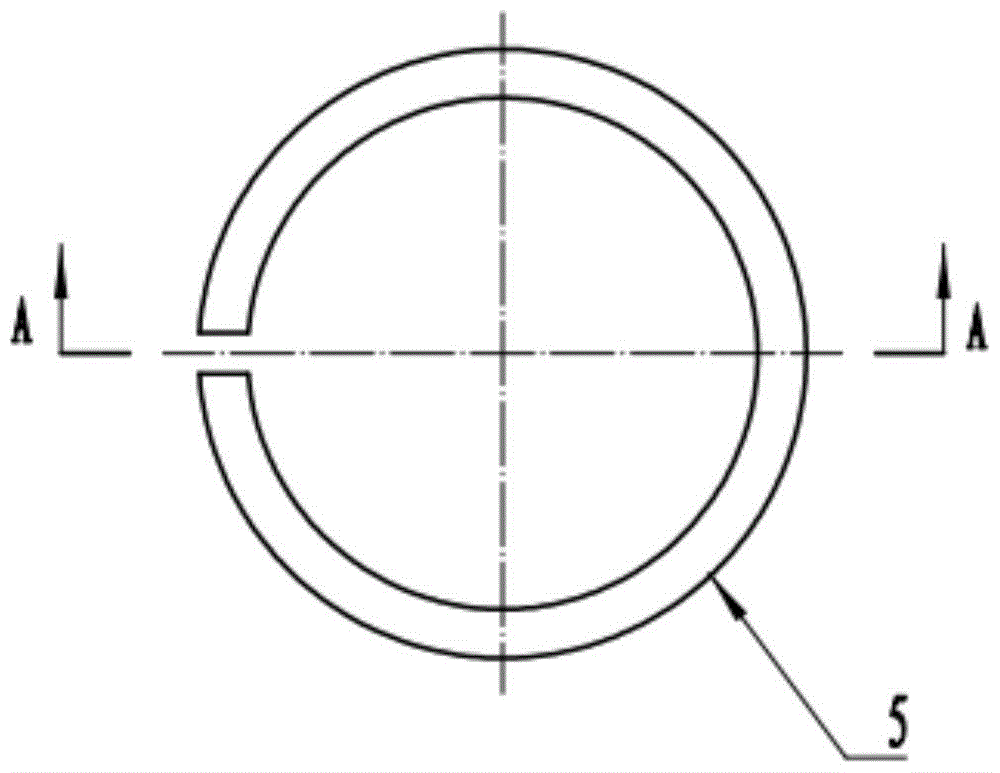

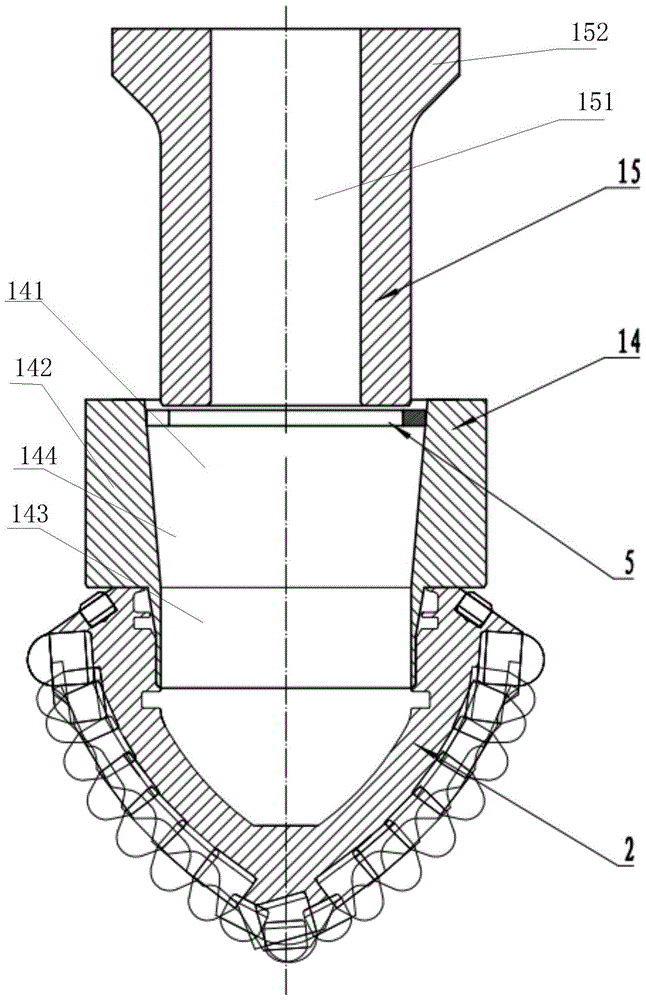

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure: a roller cone bit, including cone shaft hole 2, tooth palm shaft 1, sealing system 7, oil storage compensation pressure balance system 13, the cone shaft hole is sleeved on the tooth palm shaft, and the sealing system is set Seal the two between the cone shaft hole and the tooth palm shaft, the oil storage compensation pressure balance system communicates with the bearing center oil hole 10 on the tooth palm shaft through the long oil hole 12, the convex arc surface of the cone shaft hole The radian of the convex arc surface is the same as the shape of the bottom of the well and parallel to the bottom of the well. By adding the main bearing surface of the bearing shaft, the unstable phenomenon caused by the local force of the bearing shaft is prevented, and the stability of the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com