Cylindrical cyclone separation device and special cyclone guide ring for same

A technology of swirl separation device and guide ring, which is applied in the direction of combination device, noise reduction device, exhaust device, etc., can solve the problems of automobile engine damage, insufficient utilization rate, and insufficient reduction of carbon deposition, so as to achieve adsorption of harmful gases, The effect of reducing vehicle emissions and saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

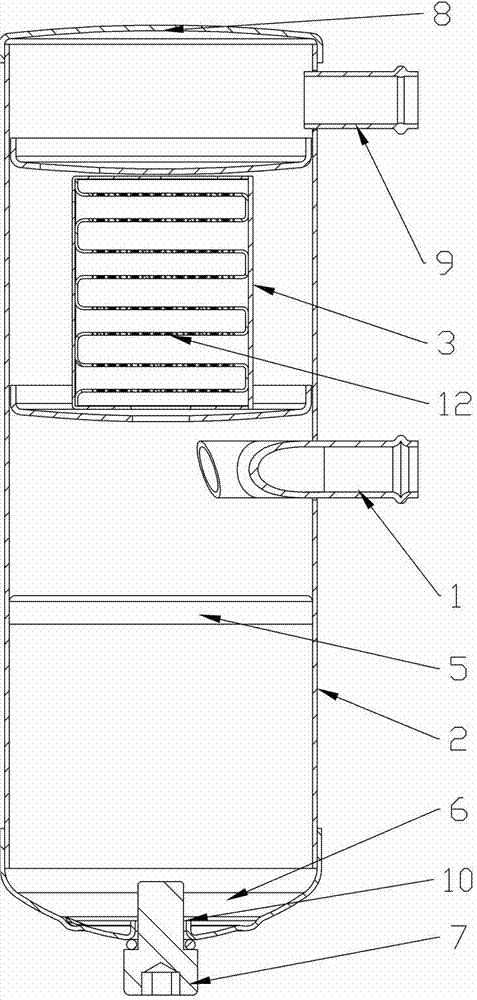

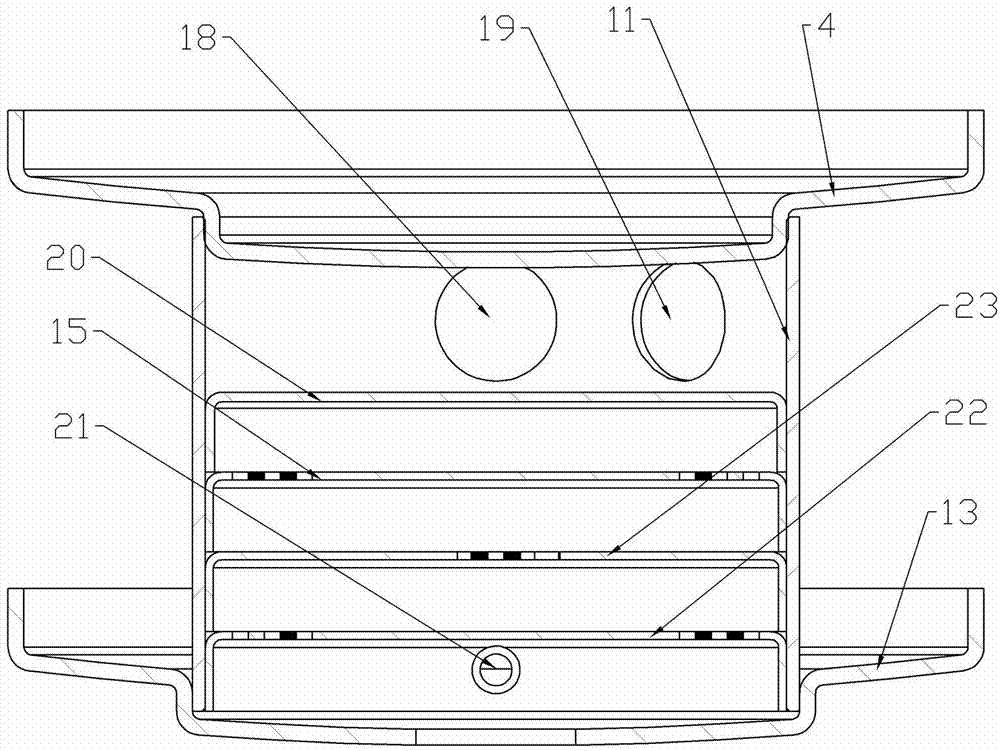

[0017] Embodiment 1, the present invention includes a cylinder 2, an air inlet pipe 1 and an outlet pipe joint 9, and is characterized in that: both ends of the cylinder 2 are sealed, and a swirl guide ring 5 is arranged in the middle and lower part of the cylinder 2 in a sealed fit. The cylinder body 2 on the upper part of the swirl guide ring 5 is provided with an air intake through hole and is sealed and fitted with the air intake pipe 1. The upper part of the air intake pipe 1 in the cylinder body 2 is provided with a lower partition 13 which is sealed and fitted with the cylinder body 2. The plate 13 divides the cylinder 2 into an upper filter chamber and a lower cyclone separation chamber. The upper part of the lower partition 13 is sealed with a filter element 3, and the lower partition 13 communicates with the cyclone chamber. The upper end of the filter element 3 is provided with a 2 The sealed upper partition 4, the upper and lower ends of the filter element 3 are res...

Embodiment 2

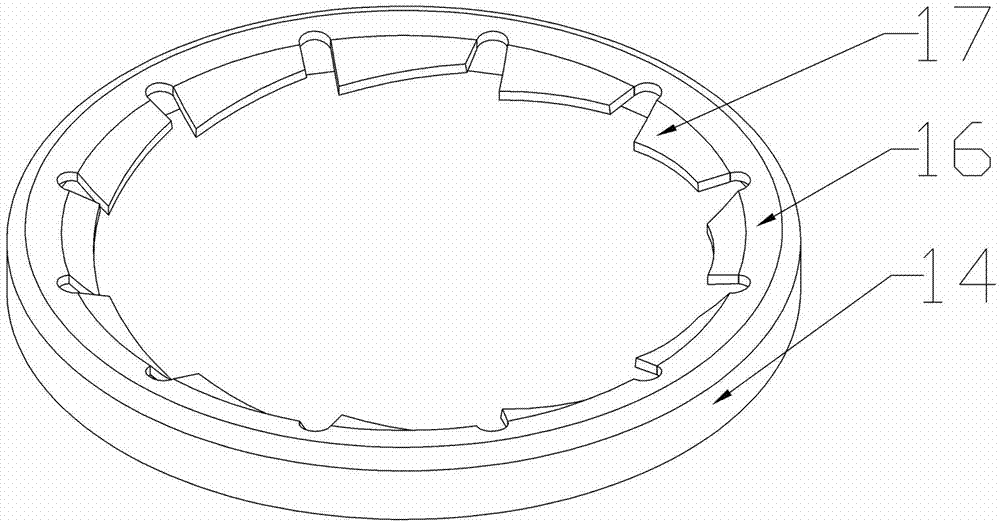

[0018] Embodiment 2, the swirl guide ring 5 of the present invention includes a ring wall 14, a blade ring 16, and a swirl guide vane 17, the blade ring 16 is arranged on the ring wall 14, and the outer diameter of the ring wall 14 is slightly larger than the inner diameter of the cylinder 2, The swirl guide ring 5 can be stuck in the cylinder body 2, and the swirl guide vanes 17 are arranged on the vane ring 16, and the surface is mirror-polished to reduce resistance. refer to Figure 1 to Figure 3 , all the other are with embodiment 1.

Embodiment 3

[0019] Embodiment 3, the vane circle 16 of the present invention is slightly inclined inward, the edge of the vane circle 16 is arc-shaped, and the vane circle 16 is provided with 3 or more swirl flow guide vanes 17, between which swirl flow guide vanes 17 The swirl guide vane 17 is inclined inwardly, the edge of the swirl guide vane 17 is high and low, the swirl guide vane 17 is set to be high on the left and low on the right, and the swirl guide vane circle 17 is in a counterclockwise direction as a whole. The air intake direction of the air pipe 1 matches, so that the gas enters and blows on the blades, which can strengthen the swirl velocity of the gas and guide the gas to form a rising swirl. refer to Figure 1 to Figure 3 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com