Control method of multi-axis motion card control system

A control system and control method technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of few motion control cassettes, non-motion control functions, inability to guarantee real-time multitasking, lack of flexibility in algorithm design, etc., to overcome Multi-thread resource sharing and mutual exclusion access conflicts, modular design, and reasonable scheduling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

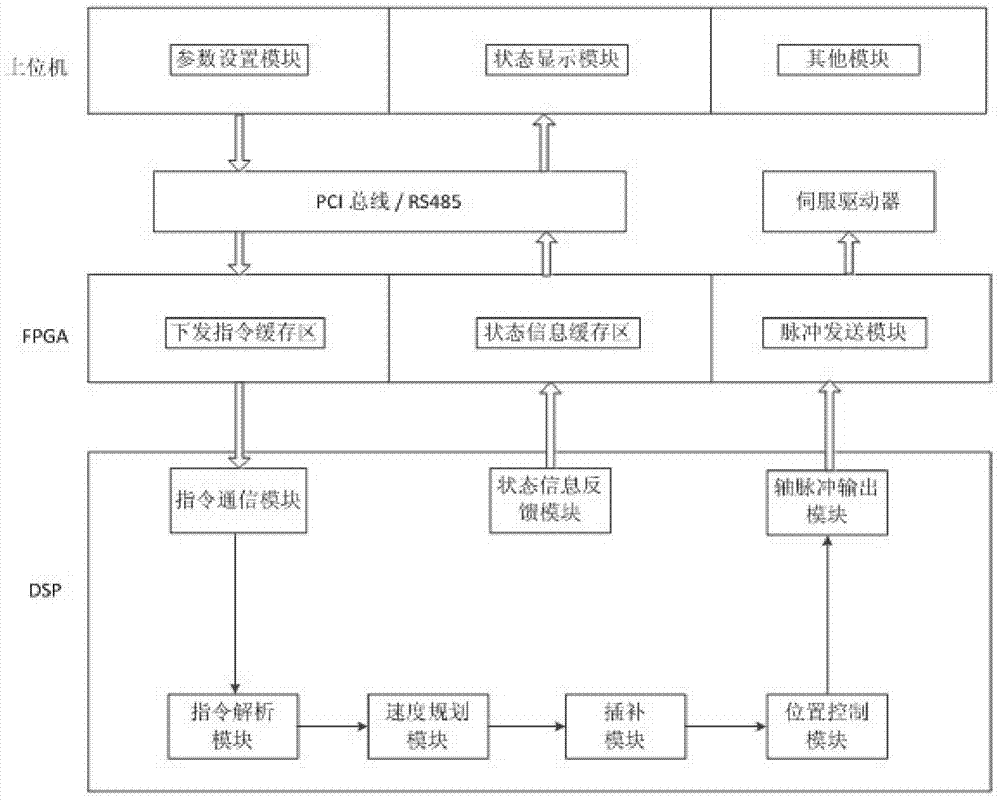

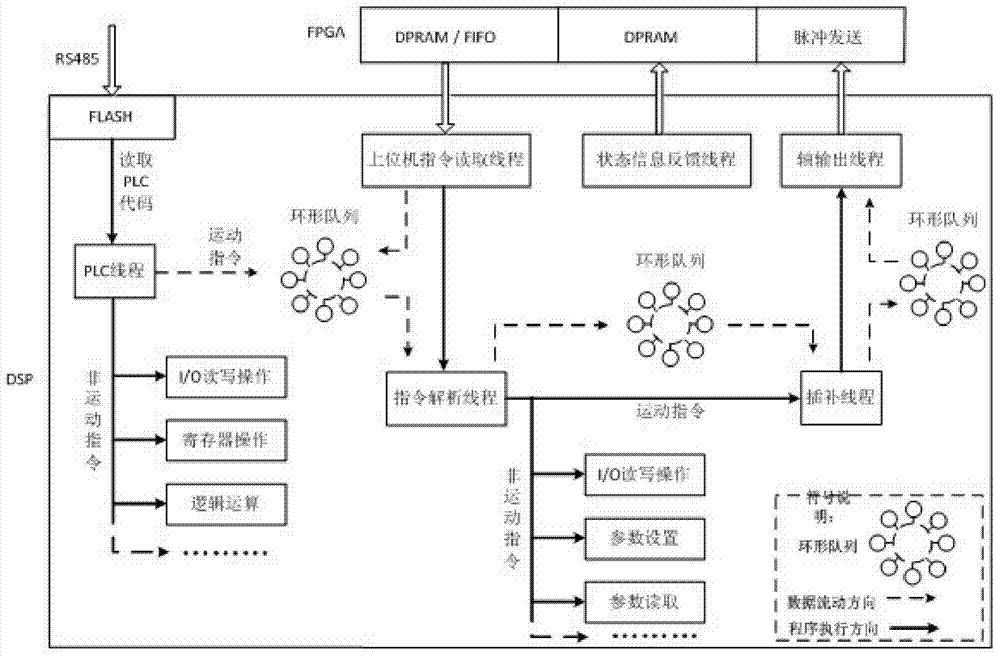

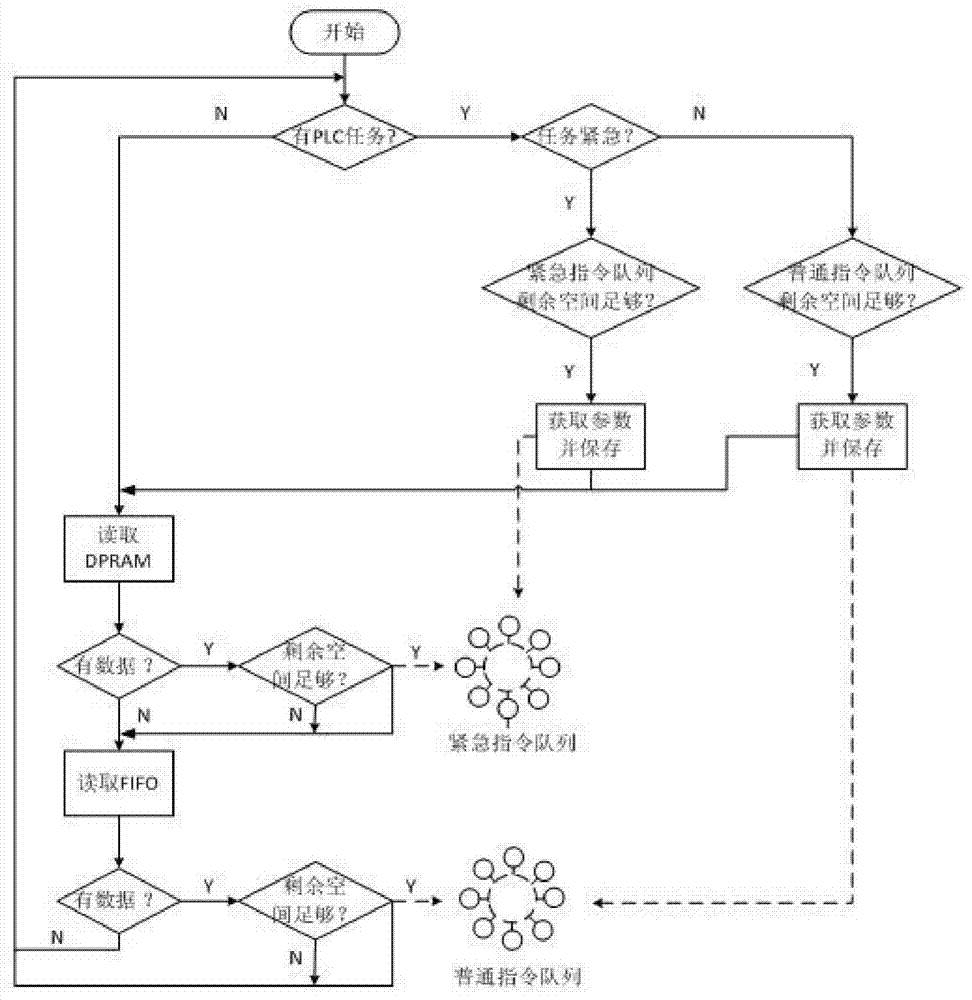

[0037] Such as figure 1 As shown, the 12-axis motion control card control system is divided into three parts: upper computer, motion control card and actuator. The user realizes system parameter setting and status information monitoring through the host computer interface; the FPGA internally realizes functions such as user command buffer, status information buffer, and output pulse transmission. There are two ways of communication between the host computer and FPGA: PCI bus and RS485 serial port; DSP It includes command communication module, command analysis module, speed planning module, interpolation module, position control module, axis pulse output module and status information feedback module. The underlying frame DSP of the 12-axis motion control card discussed in the present invention is connected to the FPGA through an EMIF (External Memory Interface, external memory interface) bus. attached figure 2 It is the underlying program architecture diagram of the 12-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com