Strain fermentation temperature control system and method

A temperature control system, fermentation temperature technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve problems such as failure to realize the interconnection of monitoring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

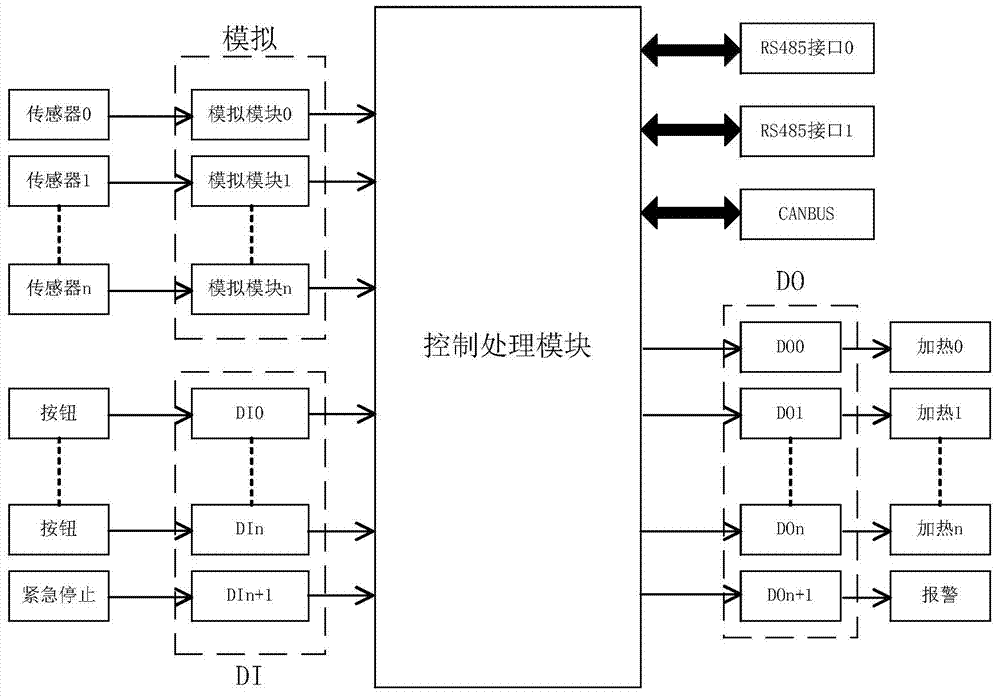

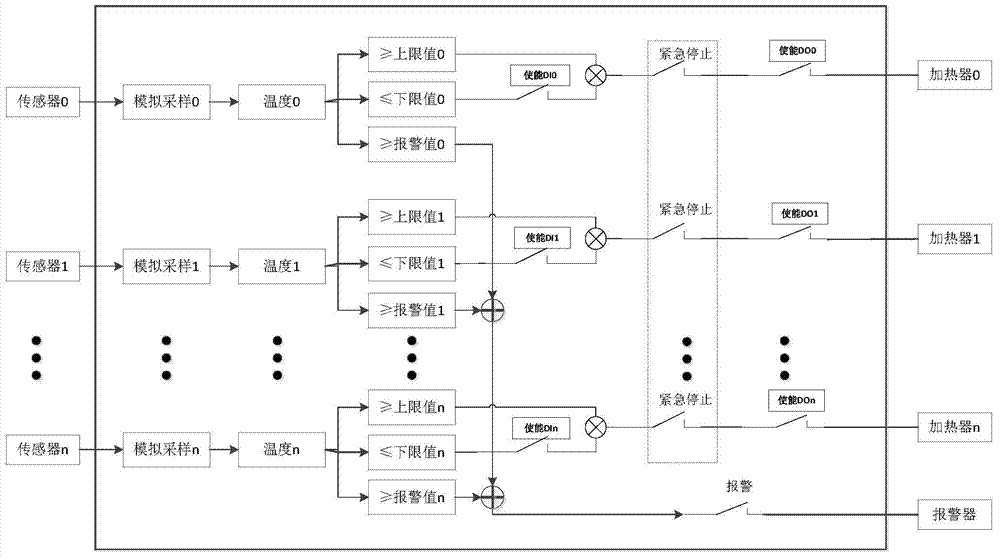

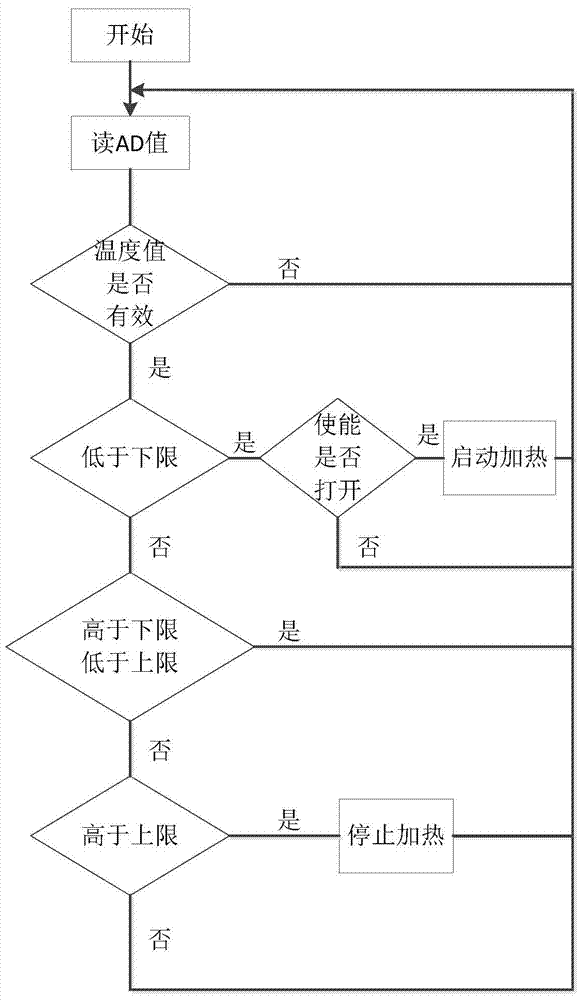

[0038] The strain fermentation temperature control system of this preferred embodiment, when used together with the strain fermentation system, is equipped with a temperature sensor, a heating device and an alarm in the fermenter of the strain fermentation system; wherein, the fermenter is a relatively airtight tank body , which is filled with a liquid mixture containing mycelium and culture medium. According to the location of the heating device, a compressed gas input interface is configured to roll and stir the liquid mixture, so that the liquid mixture in the fermenter is heated evenly. One or more temperature sensors are arranged at corresponding positions. In the actual production environment, multiple fermentation tanks work at the same time. According to the production process requirements, different strains of bacteria or the same strain are fermented in each fermentation tank. Each fermentation tank can independently complete the entire fermentation process or coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com