High-capacity electric reactor multi-point pressing method and device

A compression device and reactor technology, applied in the direction of transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, circuit, etc. problem, to achieve the effect of good versatility, simple structure and uniform pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

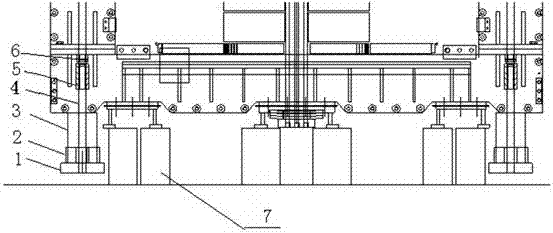

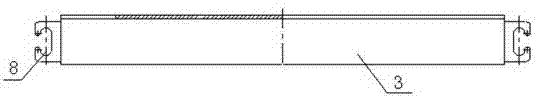

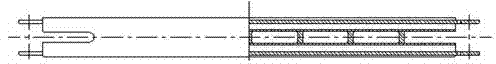

[0016] A multi-point pressing device for a large-capacity reactor, comprising a beam 3 and a tie rod extension device, U-shaped notches 8 are provided at both ends of the beam, and the tie rod extension device includes a nut 1, a screw rod 4 and a threaded sleeve 5 , the screw passes through the U-shaped slots at both ends of the beam, one end is set in the threaded sleeve, and the other end is provided with a nut, and the threaded sleeve is connected with the reactor core rod through the fixing nut 6.

[0017] The above-mentioned multi-point pressing device for a large-capacity reactor also includes a support pad 7 in its composition, and the support pad is connected to the reactor core pad for support.

[0018] A multi-point compaction method for a large-capacity reactor, comprising the following process steps:

[0019] ①Using a pressing device, the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com