A high voltage fuse

A high-voltage fuse, fuse technology, applied in electrical components, circuits, emergency protection devices, etc., can solve the problem of inconvenient removal of the solidified body, and achieve improved service life and resource utilization, convenient replacement, and good conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

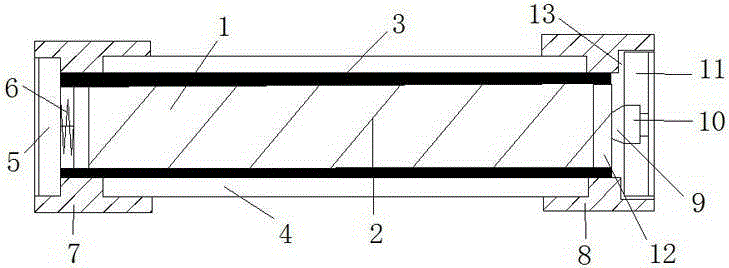

[0014] like figure 1 As shown, a high-voltage fuse includes a fuse tube 4 and a solidified body disposed in the fuse tube 4 in a detachable manner. The solidified body includes a seven-star-pillar skeleton 1, a fuse and a quartz sand layer 3 (the black solid part in the figure), the seven-star-pillar skeleton 1 is wound with a fuse, and the head and tail of the fuse are fixed on the seven-star One end of column skeleton 1 (ie figure 1 For example, the head and tail of the fuse can be spot welded on the metal cap 12, so that the current can be drawn out through the metal cap 12.

[0015] The seven-star-pillar skeleton 1 can be a ceramic seven-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com