Quantum dot and graphene photosensitive field-effect transistor and manufacturing method thereof

A technology of ene photosensitive field and field effect tube, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems affecting the stability of the electrical characteristics of field effect tubes, and achieve low cost, high responsiveness, The effect of high reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] 1. Quantum dot / graphene photosensitive field effect tube structure

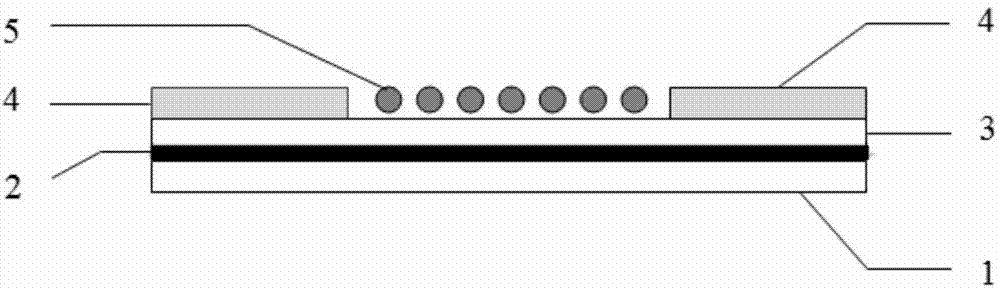

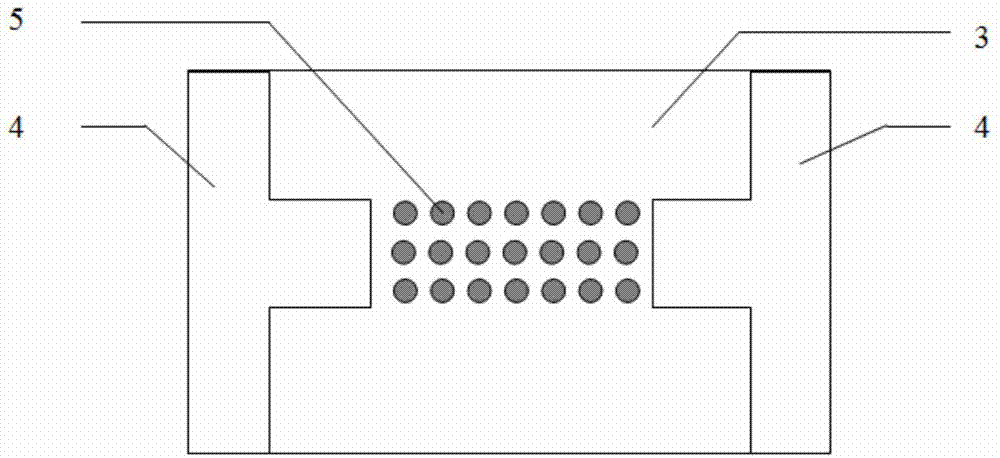

[0045] Such as figure 1 As shown, the structures of quantum dots and graphene field effect transistors are as follows from bottom to top: silicon-based substrate layer 1, silicon dioxide layer 2, graphene layer 3, electrode layer 4 and quantum dots 5.

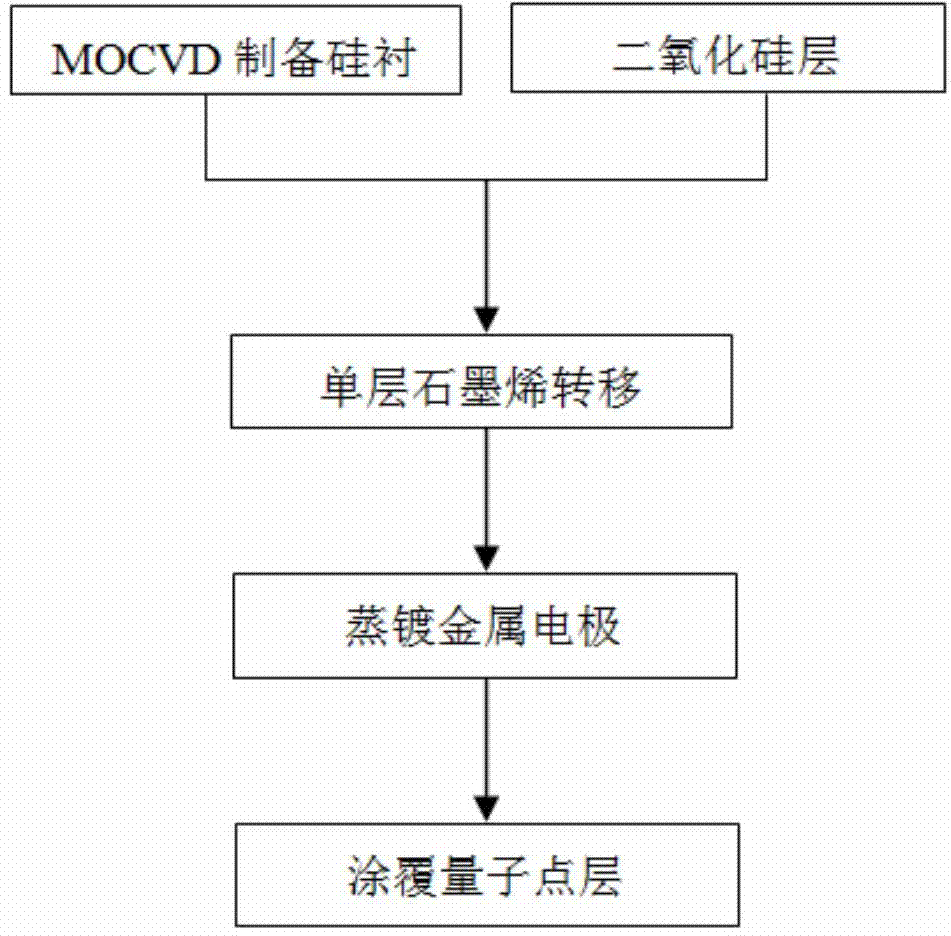

[0046] 2. Preparation of quantum dot / graphene photosensitive field effect tube

[0047]1. Preparation of silicon-based substrate layer and silicon dioxide layer

[0048] The silicon-based substrate layer was prepared by MOCVD method. The bottom layer of the substrate is highly doped single crystal silicon with a thickness of 3 μm, and the upper layer of the silicon base substrate is an oxidized silicon dioxide layer with a thickness of 300±5nm.

[0049] 2. Preparation of graphene layer

[0050] What the preparation of graphene layer adopted in this embodiment is the wet transfer method, and concrete process is as follows:

[0051] 1. Protect the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com