Copper wire welding clamp

A technology of welding fixtures and copper wires, which is applied in connection, line/collector parts, electrical components, etc., can solve problems affecting the safe use of transformers, irregular welding joints, affecting welding quality and appearance, etc., achieving simple structure, Copper wire joints are firm and smooth, satisfying the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

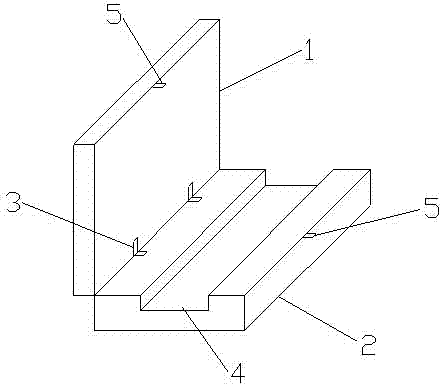

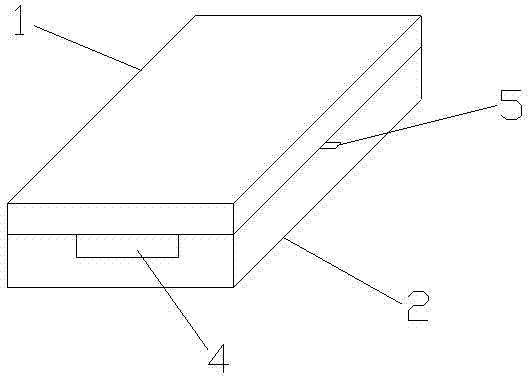

[0017] like figure 1 and figure 2 As shown, a copper wire welding jig includes an upper clamping block 1 and a lower clamping block 2, the two are fastened to each other and arranged in parallel, and are connected at the same end by a movable connector 3, and in addition, a middle part of the lower clamping block 2 is opened. There are copper wire placement grooves 4 that communicate with each other before and after, and the height of the copper wire placement groove 4 is the diameter of the copper wire. The other ends of the upper clamping block 1 and the lower clamping block 2 relative to the movable connecting member 3 are also provided with a buckling member 5 . The movable connecting piece 3 of the present invention is a hinge connecting piece; the clasping piece 5 is a locking structure, which is composed of a locking tongue and a base.

[0018] The innovation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com