A welding torch body of a welding machine head

A welding head and gun body technology, applied in welding equipment, welding accessories, characteristics of welding rods, etc., can solve the problem that the processing and manufacturing requirements of high-temperature gas-cooled reactor projects cannot be fully met, the welding seam cannot meet the quality requirements of nuclear power products, and the welding seam slope Small mouth and other problems, to achieve the effect of no dead angle monitoring, good protection effect, and sufficient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described in detail through the drawings and examples below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0090] The word "exemplary" is used exclusively herein to mean "serving as an example, embodiment, or illustration." Any embodiment described herein as "exemplary" is not necessarily to be construed as superior or better than other embodiments. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

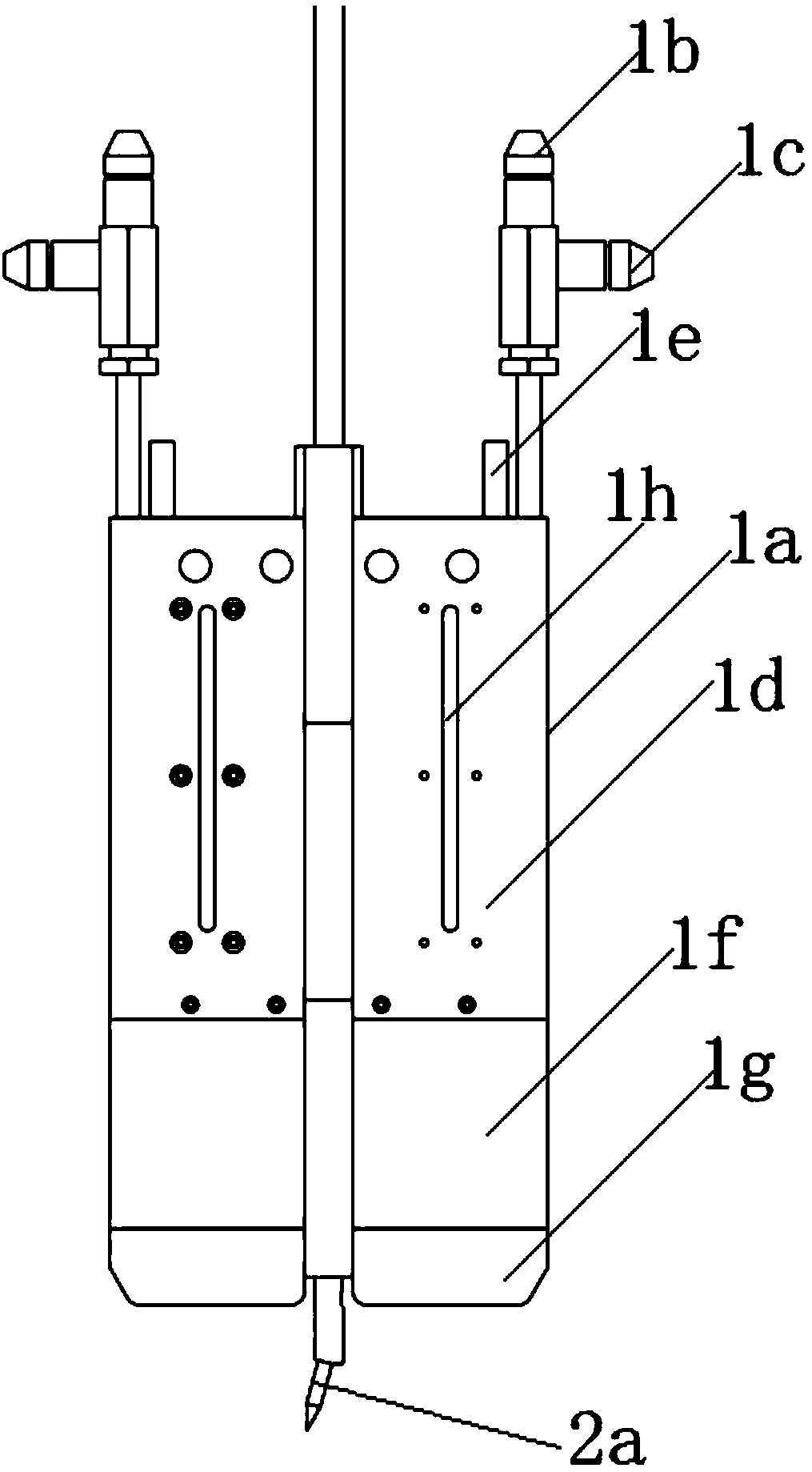

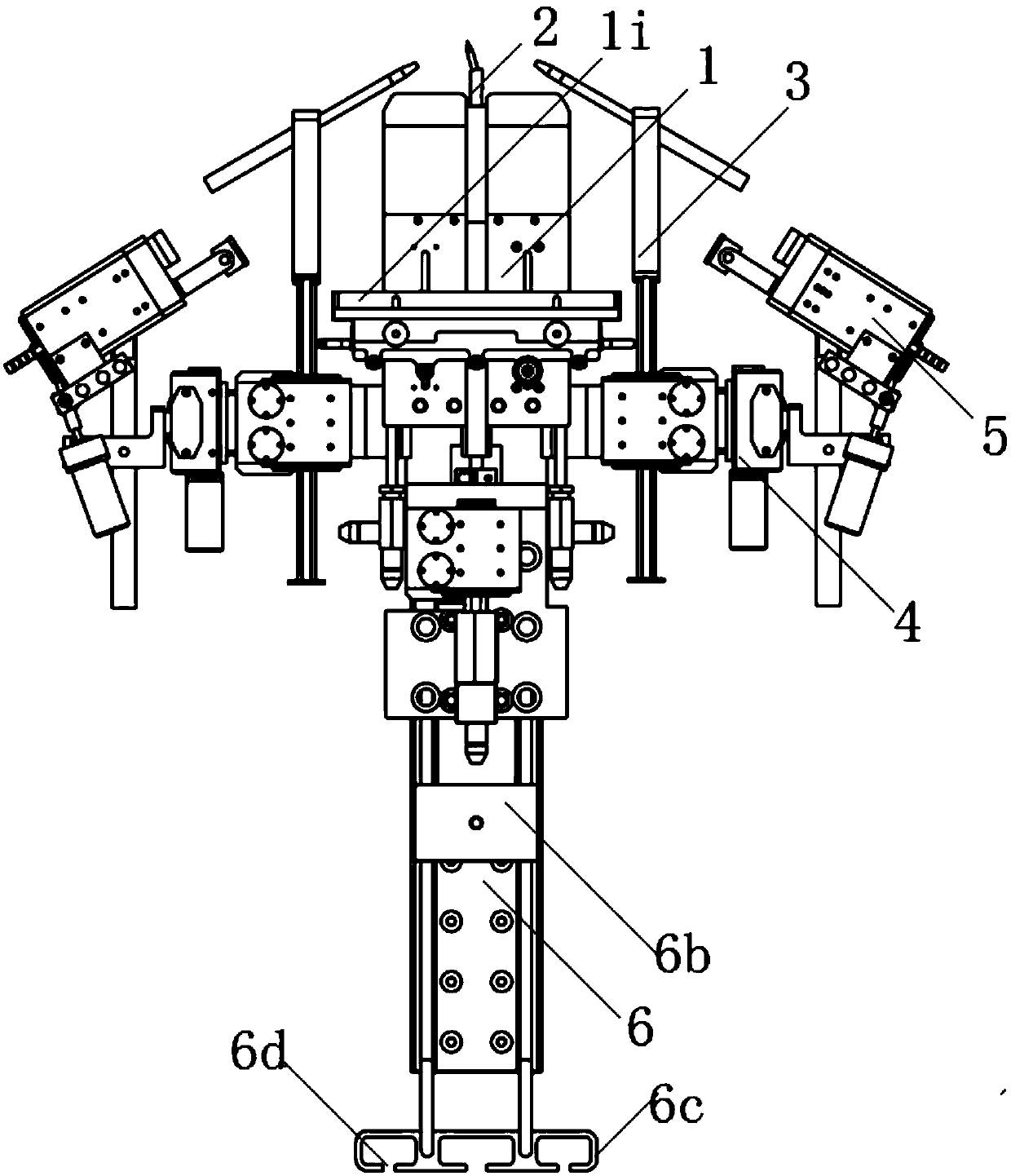

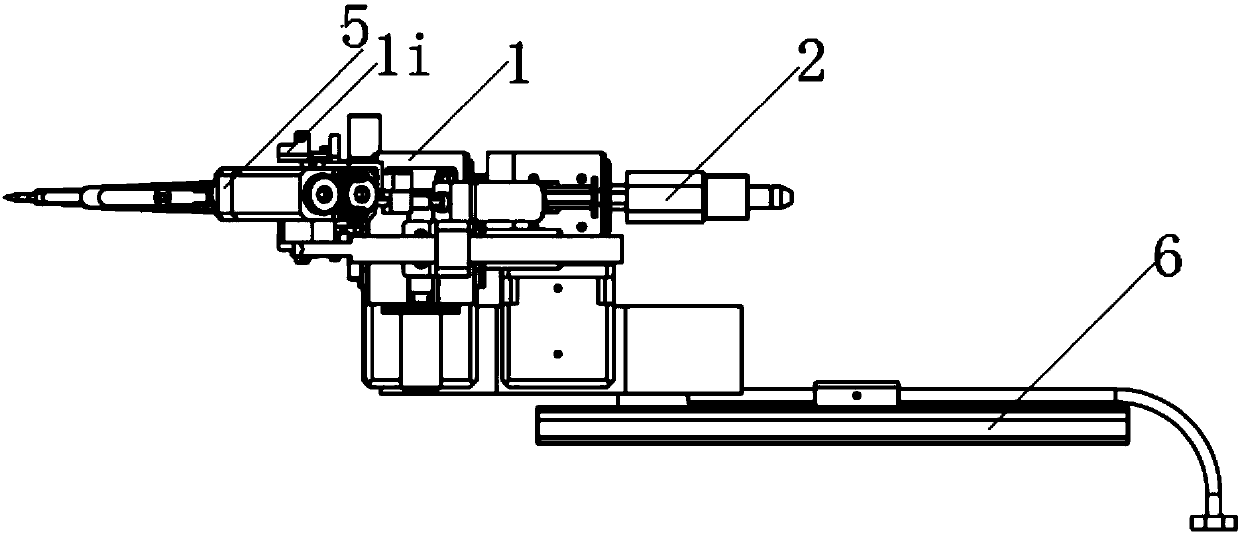

[0091] According to the welding torch body of the welding head provided by the invention, such as figure 1 As shown in , the welding torch body includes a gun body shell 1a, the gun body shell 1a is a hollow shell in a flat shape, and a cooling system and a primary gas protection system are arranged inside it, wherein the cooling system includes The cooling water inlet 1b and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com