Photovoltaic cell module terminal box of wiring window free of bus bars on surface

A photovoltaic cell and busbar technology, applied in the photovoltaic field, can solve the problems of labor-consuming, high manufacturing cost, complicated installation process, etc., and achieve the effects of reduced manufacturing, simple structure and remarkable heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

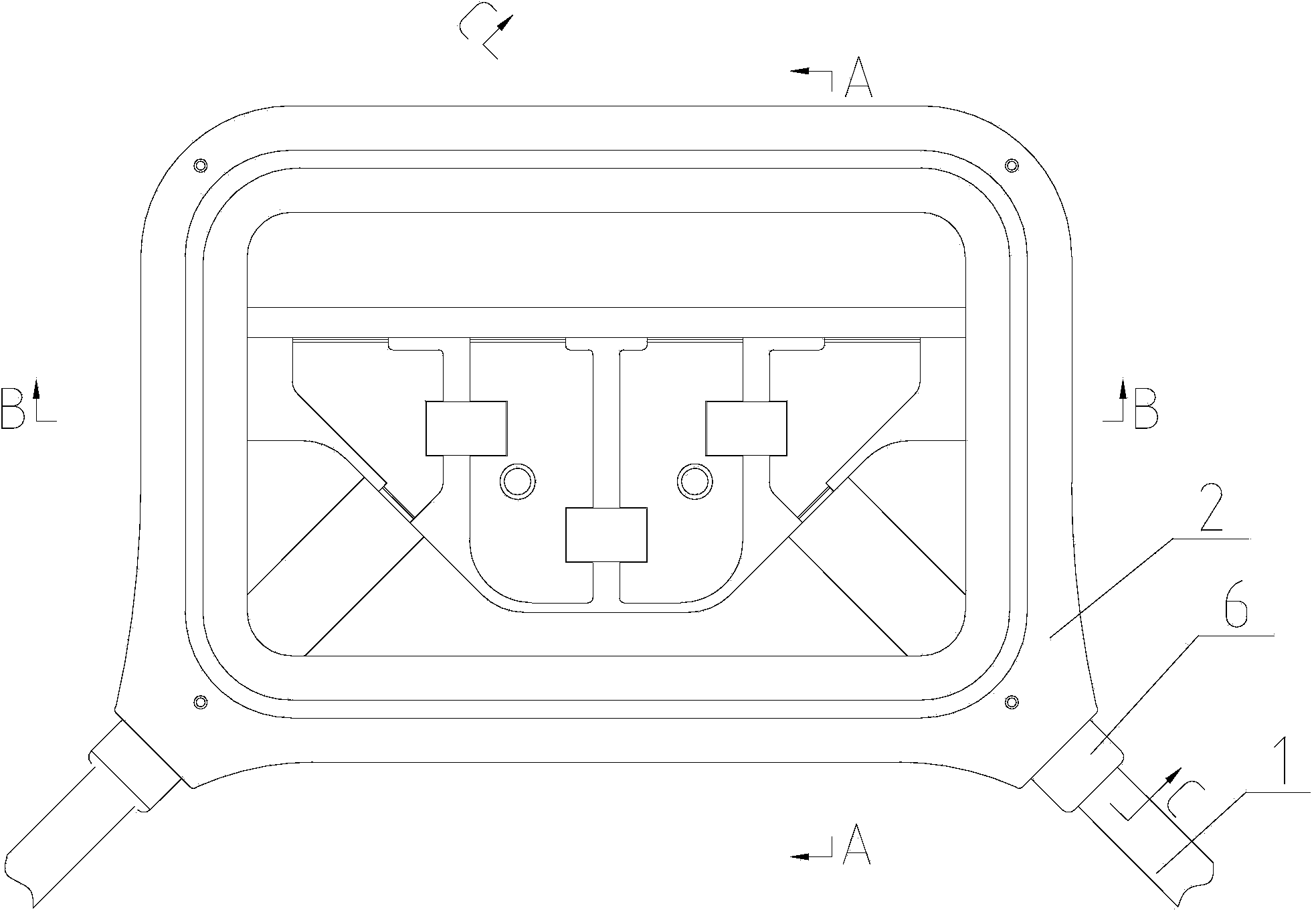

[0021] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

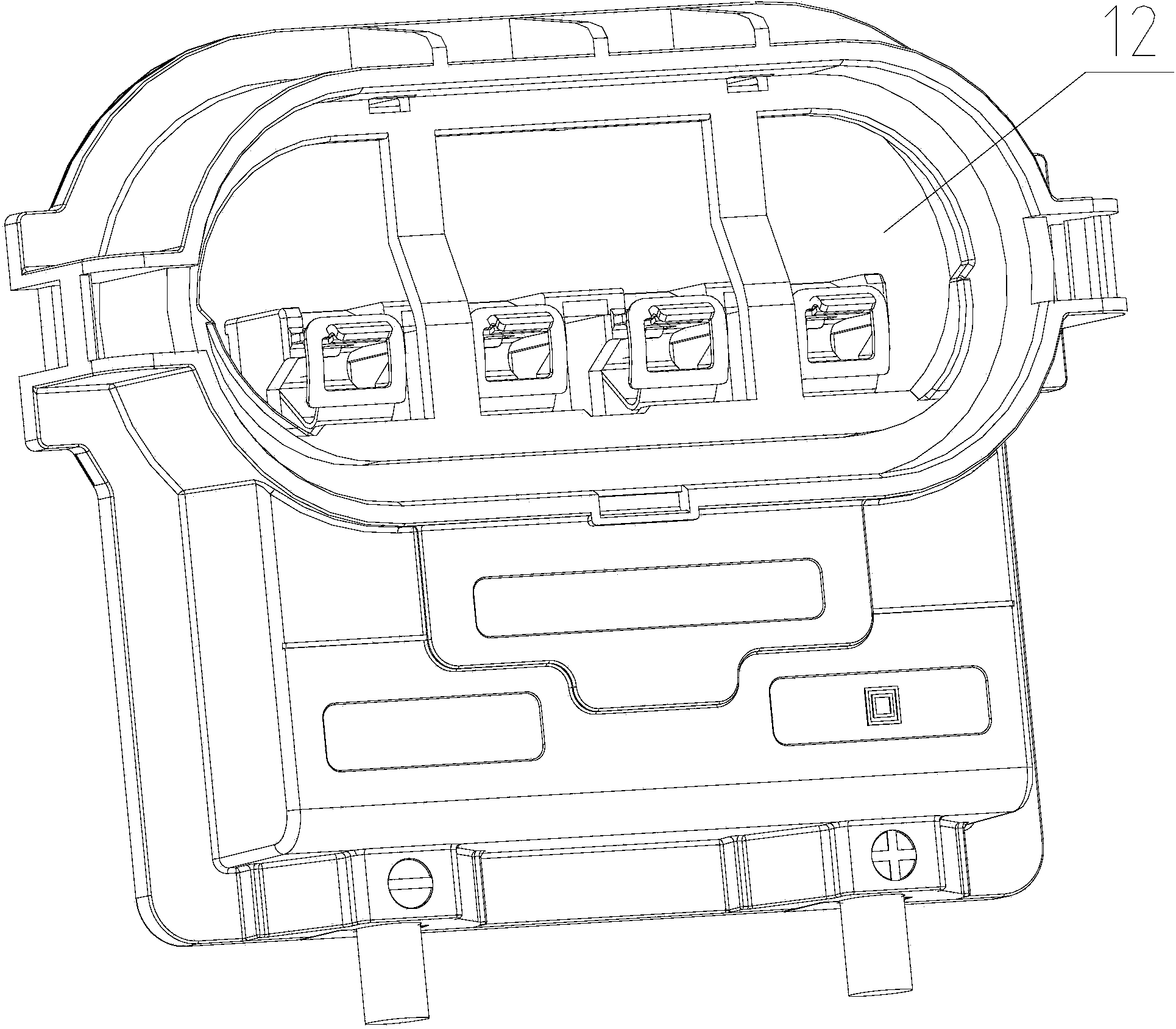

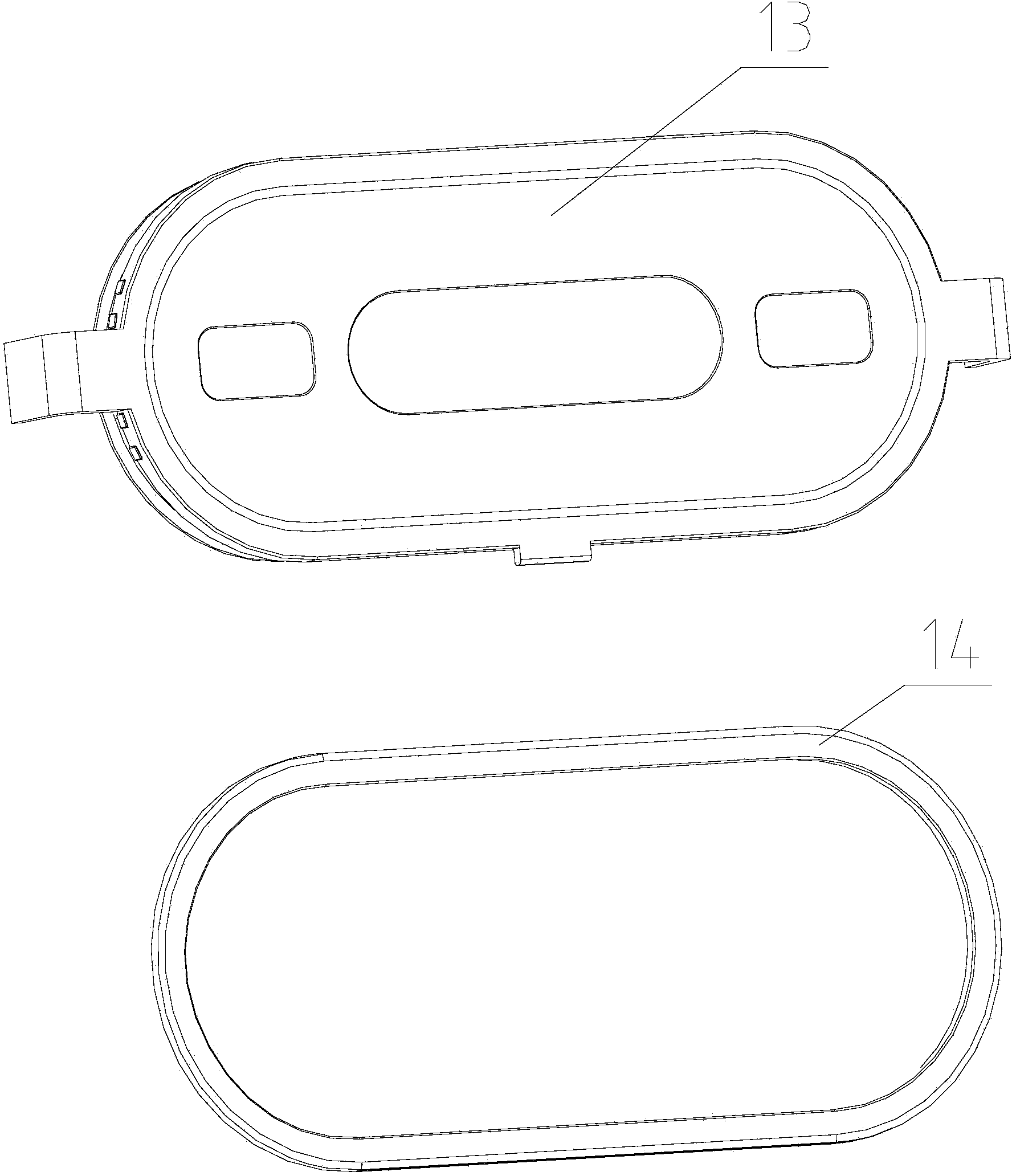

[0022] Such as Figure 1 to Figure 2 Shown is a common glue-filled junction box in the prior art. The front of the junction box has a bus bar connection window 12. After the worker fixes the junction box on the photovoltaic cell module backplane or glass 3, the bus bar Operation in the wiring window 12, after the terminal 4 is connected with the bus bar 7, the glue filling type junction box of filling the bus bar wiring window 12 and adding a plastic upper cover 13 after connecting the terminal 4 and the bus bar 7. In order to ensure the sealing of the junction box, a sealing strip 14 is also assembled in the plastic upper cover 13 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com