Controllable coolant pump with an electro-hydraulic baffle plate adjustment

A coolant pump and deflector technology, which is used in engine cooling, coolant flow control, pump device, etc., can solve problems such as rapid heating delay, and achieve the effect of reduced fuel consumption and compact structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

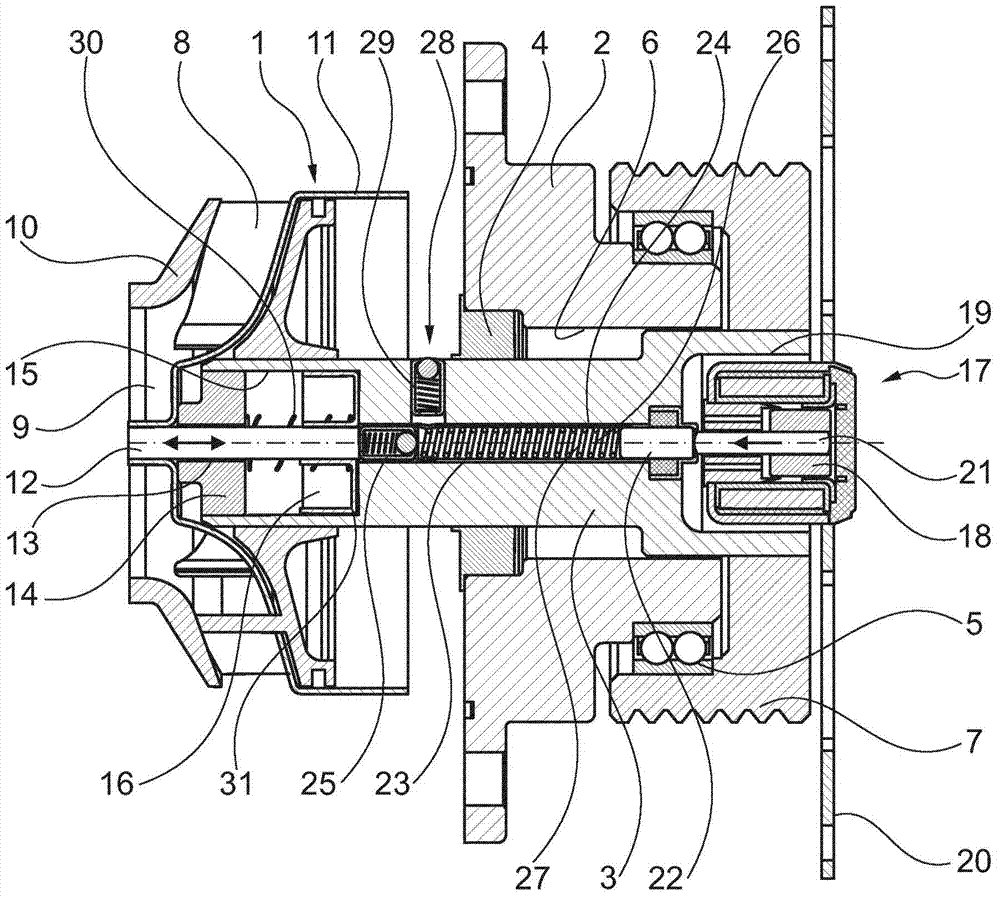

[0019] figure 1 A coolant pump 1 is shown in section, which can preferably be used for a coolant circuit of an internal combustion engine. A pump shaft 3 designed as a hollow shaft is inserted into the pump housing 2 of the coolant pump 1 , which is rotatably mounted via two bearings 4 , 5 designed in particular as roller bearings. The first bearing 4 is inserted into the bore 6 of the pump housing 2 , while the second bearing 5 is inserted between the shoulder of the pump housing 2 and the axial receptacle of the belt pulley 7 fixed in rotation on the pump shaft 3 between. The drive of the coolant pump 1 takes place via a traction mechanism drive (not shown), wherein a traction mechanism, a belt or a chain connects the drive disc 7 to other drive discs. An impeller 8 arranged opposite the drive disk 7 on the pump shaft 3 is associated with a suction chamber 9 with which, in the operating state of the coolant pump 1 , the coolant is delivered radially as a volume flow to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com