A method for dehumidifying tobacco leaves

A technology of tobacco leaf and dehumidifier, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of tobacco leaf discoloration and deterioration, uneven dehumidification of tobacco leaves, and long dehumidification cycle, so as to improve the utilization of space, improve the dehumidification effect, and shorten the dehumidification cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

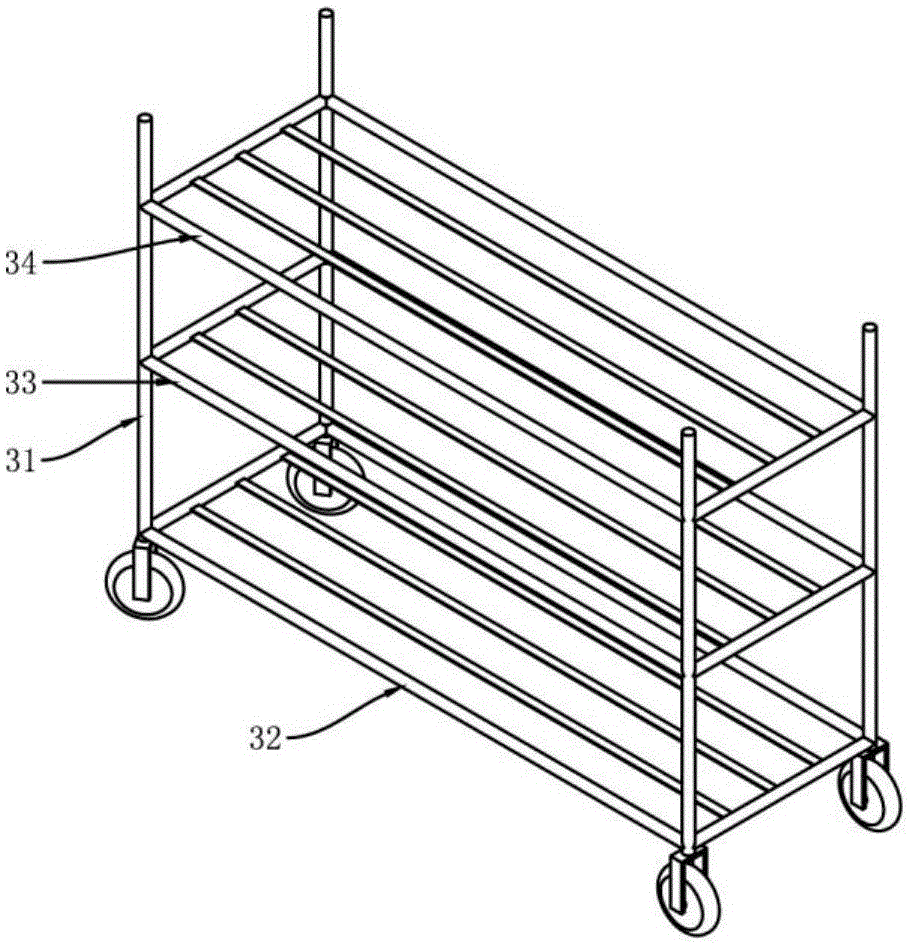

[0041] Tobacco leaves are dehumidified using the above method. The average moisture content of the smoke to be dehumidified is 20%, the temperature in the dehumidification room is 23°C, and the relative humidity is RH72%.

[0042] 2 hours after the dehumidifier is turned on, the temperature below 1.2M in the dehumidification chamber is 35°C, the temperature above 1.2M is 32°C-34°C, the temperature difference between the upper and lower spaces of the dehumidification chamber is 3°C, the humidity is 85% below 1.2M, and above 1.2M The humidity is 80%-75%, and the relative humidity difference is 10%. As the dehumidification time goes by, the temperature difference between the upper and lower layers of the dehumidification chamber will gradually decrease, and after another 3-4 hours, it will reach a constant temperature of 35°C. At the same time, the relative average humidity of the upper and lower layers will increase and reach 80%, and a large amount of water in the tobacco leaves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com