Tube purification unit for sustainable production of evaporable materials

A continuous production, tubular technology, applied in chemical instruments and methods, separation methods, sublimation, etc., can solve the problems of difficult industrialization, low, and difficult to sustain production efficiency, save time and energy, increase revenue, High purity and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

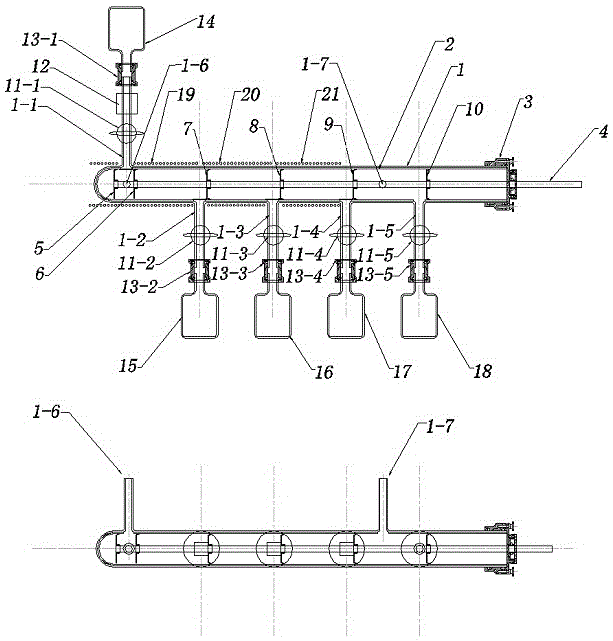

[0029] Such as figure 1 As shown, a tubular purification device for sustainable production of evaporable materials includes an outer tube 1, an inner tube 2, a vacuum head 3, a push-pull rod 4, a leveling disc 5, a first scraping disc 6 with a gap, The second scraping disc 7, the third scraping disc 8, the fourth scraping disc 9, and the air-blocking disc 10; the outer tube 1 has a feed tube 1-1, a first discharge tube 1-2, and a first discharge tube 1-2. Two discharge pipes 1-3, the third discharge pipe 1-4, the fourth discharge pipe 1-5, the air inlet pipe 1-6 and the exhaust pipe 1-7, the diameter of the inner pipe 2 is smaller than the outer pipe 1 , which can fit tightly inside the outer tube 1, and have corresponding openings at each outlet of the outer tube 1; The push-pull rod 4 is connected to the push-pull rod 4 in turn with a leveling disc 5, a first scraper disc 6, a second scraper disc 7, a third scraper disc 8, a fourth scraper disc 9, and an air barrier disc 1...

Embodiment 2

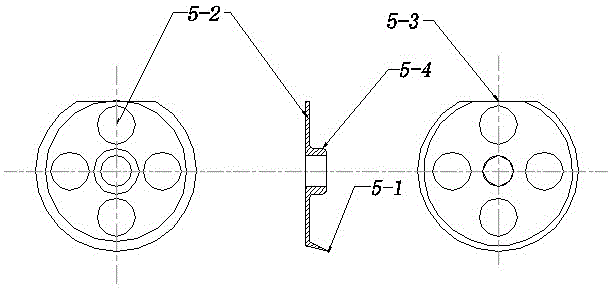

[0032] Such as Figure 2 to Figure 5 As shown, the screed disc 5 described in this embodiment is made of stainless steel, molybdenum, titanium or high-temperature alloy; there is a first connection sleeve hole 5-4 connecting the push-pull rod 4 in the middle of the screed disc 5, There is a first knife edge 5-1 close to the inner tube 2 on the periphery, a number of first vent holes 5-2 inside, and a first notch 5-3 on the top. The position of the first notch 5-3 is consistent with the first scraping material The second notch 6-5 of the disc 6 corresponds.

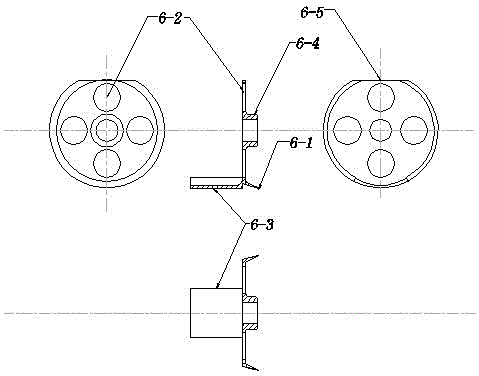

[0033] The notched first scraping disc 6 is made of stainless steel, molybdenum, titanium or high-temperature alloy; there is a second connecting sleeve hole 6-4 connecting the push-pull rod 4 in the middle of the first scraping disc 6, There is a second knife edge 6-1 close to the inner tube 2 on the periphery, a number of second ventilation holes 6-2 inside, and a feeding tube 1-1 on the inner tube 2 on the other side o...

Embodiment 3

[0037] Such as Image 6 As shown, the purification process of this embodiment is basically the same as that of Embodiment 1, the difference is that the feed device 12 consists of a rotary column valve body 12-1-1, a columnar valve core 12-1-2, and The charging cavity 12-1-3 and the connecting pipe 12-1-4 are composed. The charging cavity 12-1-3 is placed in the columnar valve core 12-1-2 and one side is closed, and the rotating columnar valve core 12- 1-2. When the charging cavity 12-1-3 is aligned with the charging port 12-1-5 above the rotary column valve body 12-1-1, the powder material falls into the charging cavity 12-1- 3, and then rotate the cylindrical valve core 12-1-2180 degrees so that the charging cavity 12-1-3 is aligned with the discharge port 12-1-6 below the rotating column valve body 12-1-1, The powder material enters the feeding pipe 1-1 through the connecting pipe 12-1-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com