A high-precision spherical deep hole processing equipment

A processing equipment and high-precision technology, applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of incalculable price and high price, and achieve novel structural design, high processing accuracy, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described below in conjunction with specific embodiments.

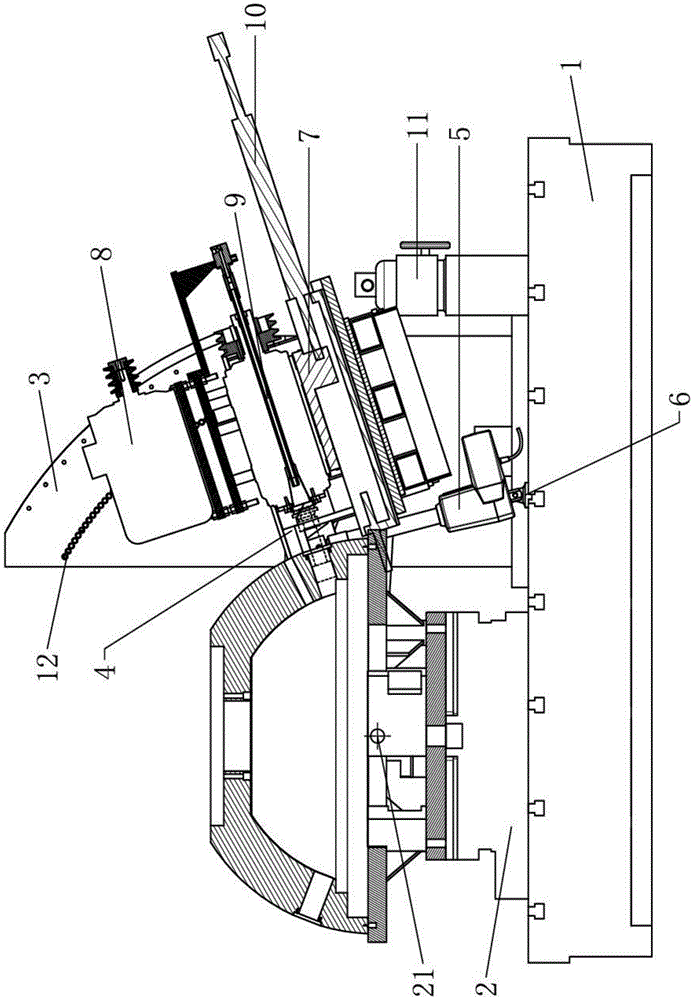

[0023] Such as figure 1 As shown, a high-precision spherical deep hole processing equipment includes a base 1, a rotary table 2 is installed on the top of the base 1 in a relatively rotatable manner, and a vertical table is installed on the side of the rotary table 2 above the base 1 To the extended column 3, the rotary table 2 has a rotary table center 21 that is at the same position as the center of the spherical part. The front end side of the column 3 is relatively rotatably equipped with a movable support frame 4, and the center of rotation of the movable support frame 4 It is aligned front and rear with the center 21 of the rotary table, and an angle locking device is installed between the movable support frame 4 and the column 3 .

[0024] Further, a jacking hydraulic cylinder 5 is installed between the movable support frame 4 and the base 1, and the base 1 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com