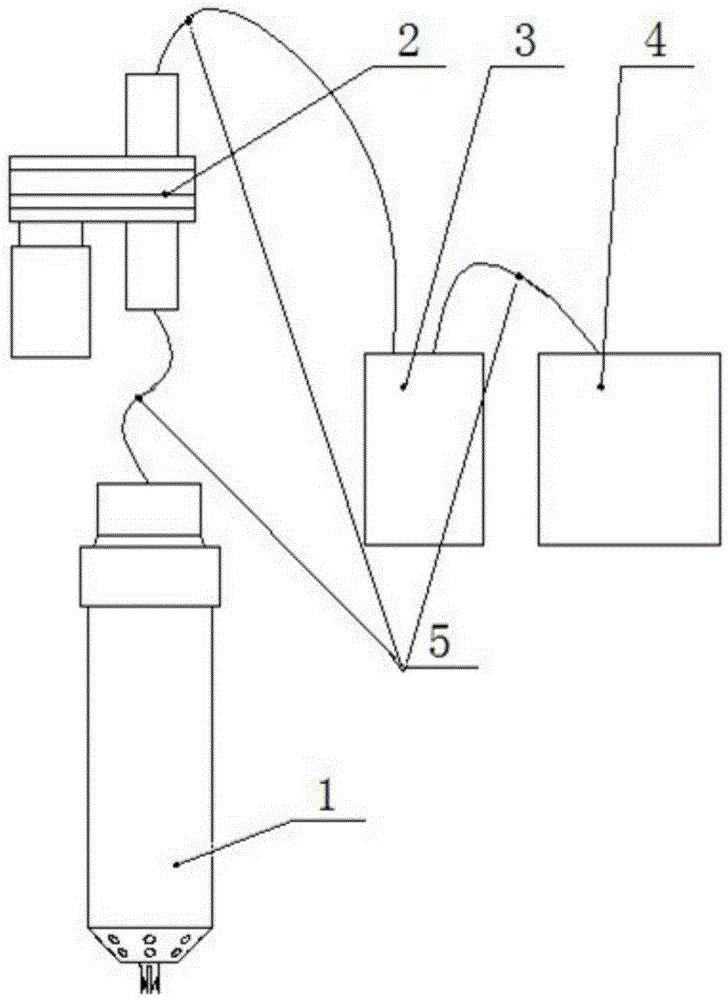

an air drill

An air drill and drill bit technology, which is used in repairing drills, drilling tool accessories, portable drilling rigs, etc., can solve the problems of no dust removal device, dislocation of punching points, excessive chips and powders, etc., and achieves simple and reliable structure and punching point position. Precise, rounded hole cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

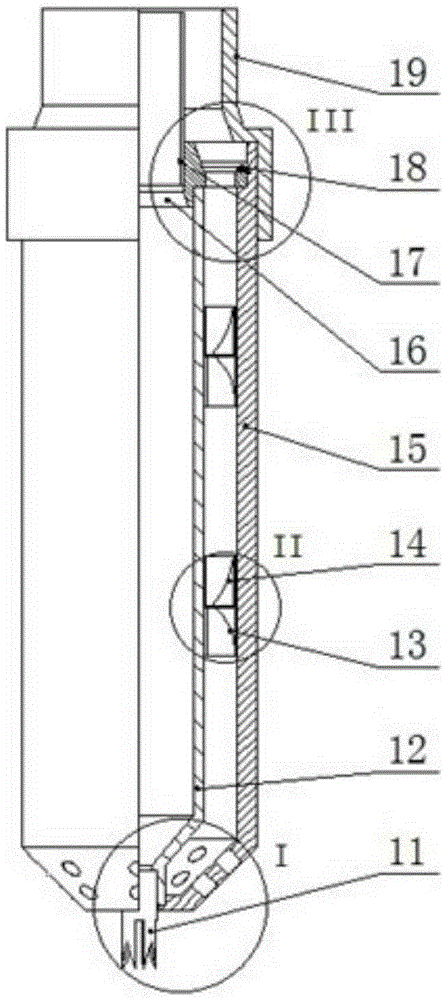

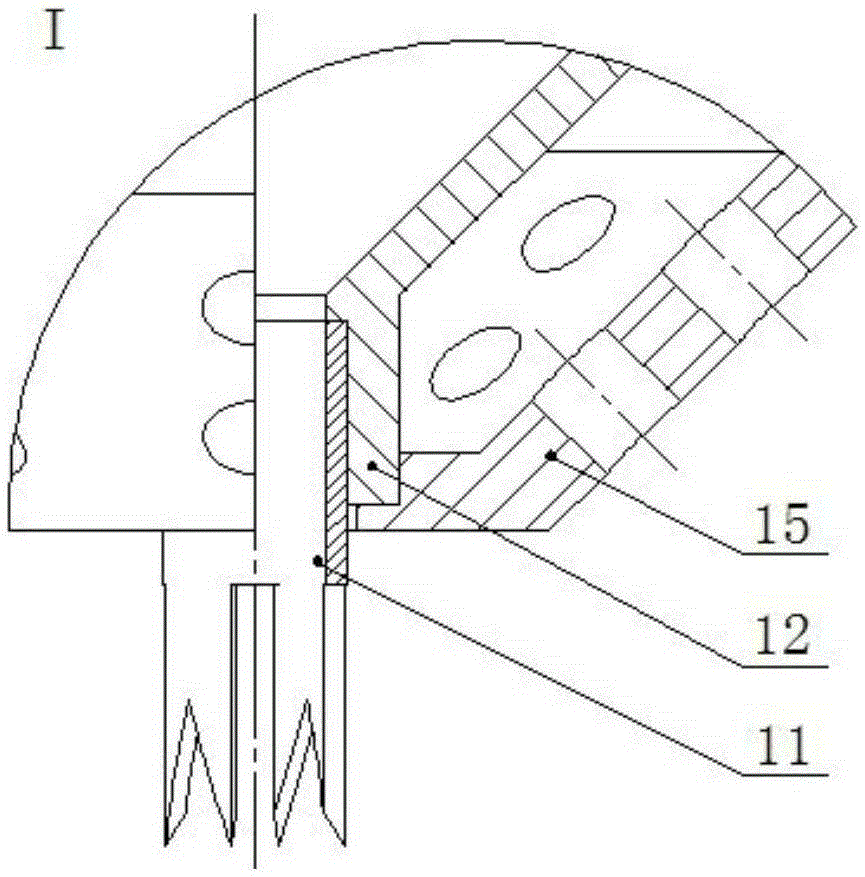

[0026] In this embodiment, the drill bit 11 is an axially penetrating hollow drill bit (see image 3 ), and is provided with a cutting edge at the lower end. The drill bit 11 includes 3 sets of cutting edges. The shape of a single set of cutting edges is "M". There is a gap between two adjacent sets of cutting edges. The ratio of the gap width to the cutting edge width is 0.5 , The ratio of clearance depth to cutting edge depth is 2.

[0027] Sleeve 15 (see figure 2 , image 3 with Figure 5 ) There are 15 vent holes in the front section, and the inner cylinder wall at the inner end of the end is provided with an annular groove for installing the elastic retaining ring 18. The side of the annular groove opposite to the air distribution plate 16 is an inclined surface and is connected to the air distribution plate 16 The radial plane is 45°.

[0028] Guide impeller 13 and rotor impeller 14 (see figure 2 with Figure 4 ) Are ring-shaped, with 30 blades in the circumferential direct...

Embodiment 2

[0032] In this embodiment, the drill bit 11 includes 5 groups of cutting edges. The shape of a single group of cutting edges is "M". There is a gap between two adjacent groups of cutting edges. The ratio of the gap width to the cutting edge width is 0.3. The depth ratio is 3.

[0033] The sleeve 15 has 20 vent holes in its front section. The inner cylinder wall at the inner end of the sleeve 15 is provided with an annular groove for installing the elastic retaining ring 18. The side of the annular groove opposite to the air distribution plate 16 is an inclined surface and is connected to The radial plane of the gas disk 16 is 30°.

[0034] The guide impeller 13 and the rotor impeller 14 are provided with 25 blades in the circumferential direction. The blades are at 45° to the axial direction. The rotor impeller 14 and the guide impeller 13 are provided with gaps on the opposite end faces, and the blades of the two are in opposite directions. The number of guide impellers 13 and ro...

Embodiment 3

[0038] In this embodiment, the drill bit 11 includes two groups of cutting edges. The shape of a single group of cutting edges is "M". There is a gap between two adjacent groups of cutting edges. The ratio of the gap width to the cutting edge width is 1. The ratio of depth is 1.3.

[0039] The sleeve 15 has 10 vent holes in its front section. The inner cylinder wall at the inner end of the sleeve 15 is provided with an annular groove for installing the elastic retaining ring 18. The side of the annular groove opposite to the air distribution plate 16 is an inclined surface and is connected to The radial plane of the gas disk 16 is 60°.

[0040] The guide impeller 13 and the rotor impeller 14 are provided with 18 blades in the circumferential direction, and the blades are at 60° to the axial direction. The rotor impeller 14 and the guide impeller 13 are provided with gaps on the opposite end faces, and the blades of the two are in opposite directions. The number of guide impellers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com