Plate hot press

A hot press and plate technology, applied in the field of plate heat presses, can solve the problems of glue opening, easy cracks, and poor bonding around the plate, and achieve the effects of improving quality, improving production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

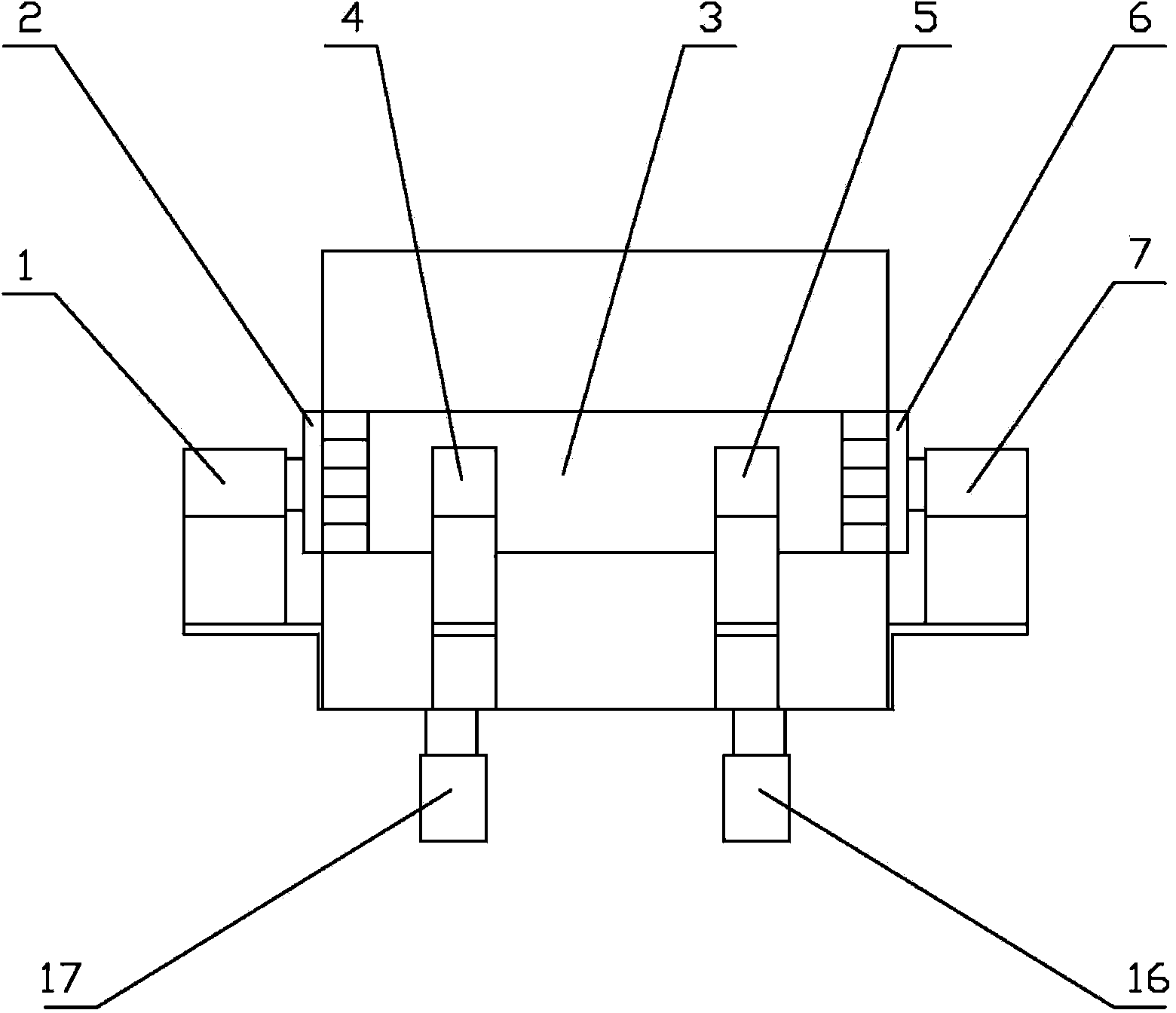

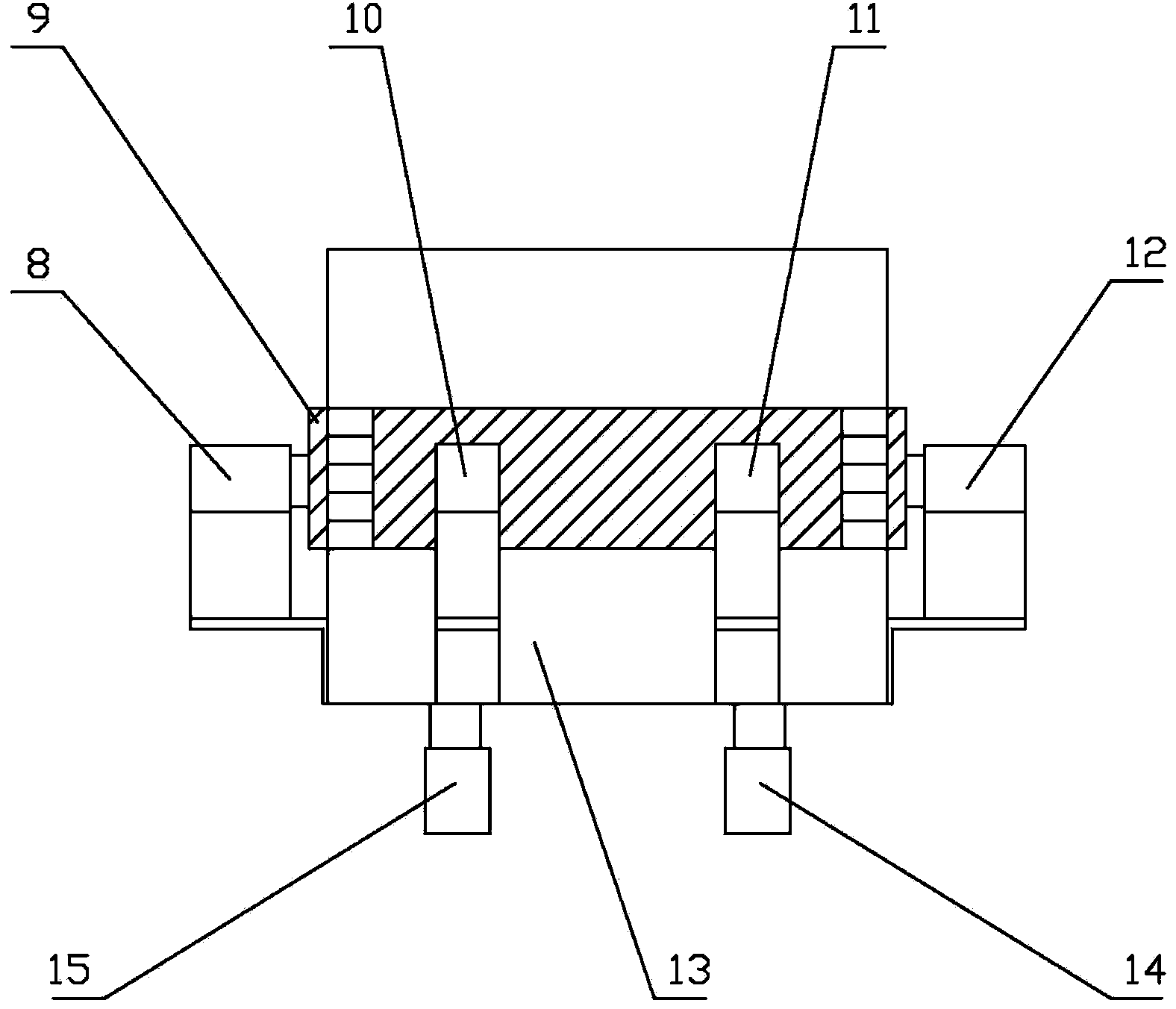

[0017] Such as figure 1 , figure 2 As shown, the plate hot press includes a lower pressure transmission device arranged below to force the upper and lower sides of the plate. The lower pressure transmission device includes a lower hydraulic cylinder I14, a lower hydraulic cylinder II15, a lower hydraulic Cylinder III16 and lower hydraulic cylinder IV17 also include left pressure transmission device, said left pressure transmission device includes left hydraulic cylinder I1 and left hydraulic cylinder II12 connected to left pressure plate 2; right pressure transmission device, said right pressure transmission device includes connection The right hydraulic cylinder I7 and the right hydraulic cylinder II8 of the right pressure plate 6; the front pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com