High-speed laterally-taken type in-mould labeling system and control method thereof

A technology of in-mold labeling and high-speed side, which is applied in the direction of coating, etc., can solve the problems of increasing cost and mechanism volume, and achieve the effect of saving time and improving the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

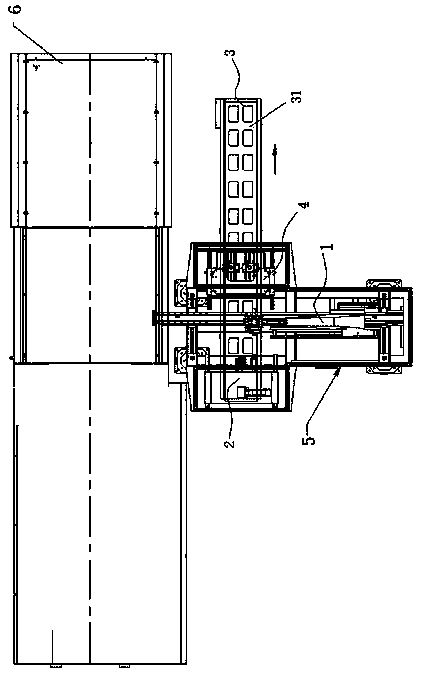

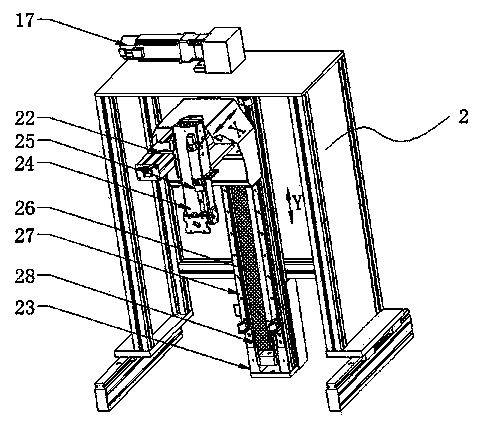

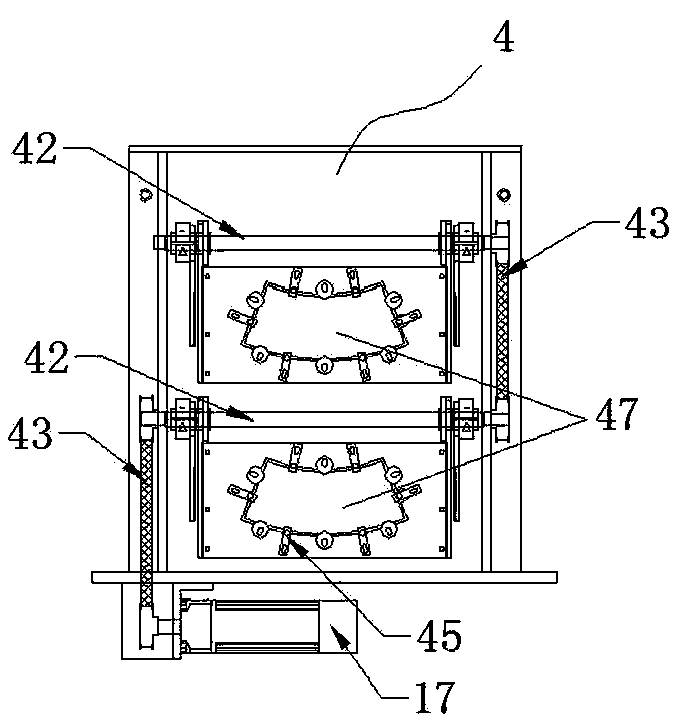

[0035] Examples, see Figure 1~Figure 7 , the high-speed side-feeding in-mold labeling system provided in this embodiment includes a frame 5, which also includes a side-feeding robot arm 1, a stacking device 2, a product conveying device 3 and a label paper arranged on the frame 5 The transmission mechanism 4 is respectively provided with a product taking fixture 12 and a labeling fixture 13 on both sides of the head of the side-taking mechanical arm 1. In the head of the side-taking mechanical arm 1, the product taking fixture 12 and labeling fixture 13 A rack and pinion transmission mechanism 14 is also provided in the middle of the jig 13, and the rack and pinion transmission mechanism 14 is connected to the backs of the product jig 12 and the labeling jig 13 respectively, and synchronously controls the product jig 12 and the labeling jig 12. The tool 13 translates in a direction perpendicular to the direction of motion of the side-taking robot arm 1; the frame 5 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com