Horizontal stacking road cone conveying mechanism for traffic road cone vehicle

A technology of conveying mechanism and traffic road, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low conveying efficiency, difficult installation, small force arm, etc., and achieve high conveying efficiency, simple structure, and driving force. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

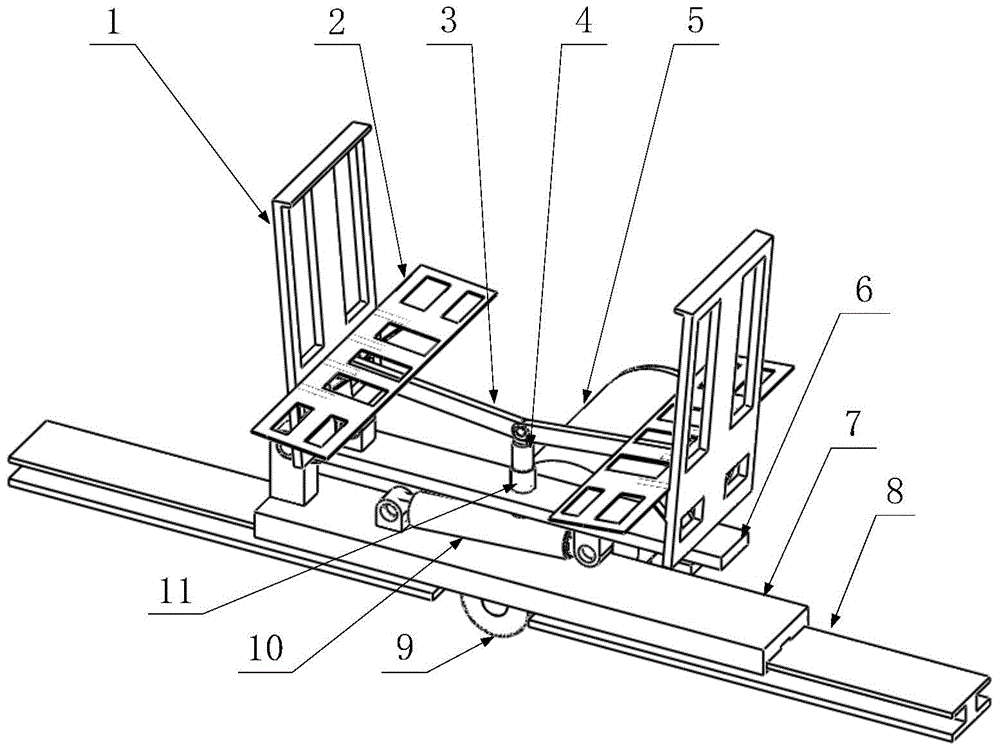

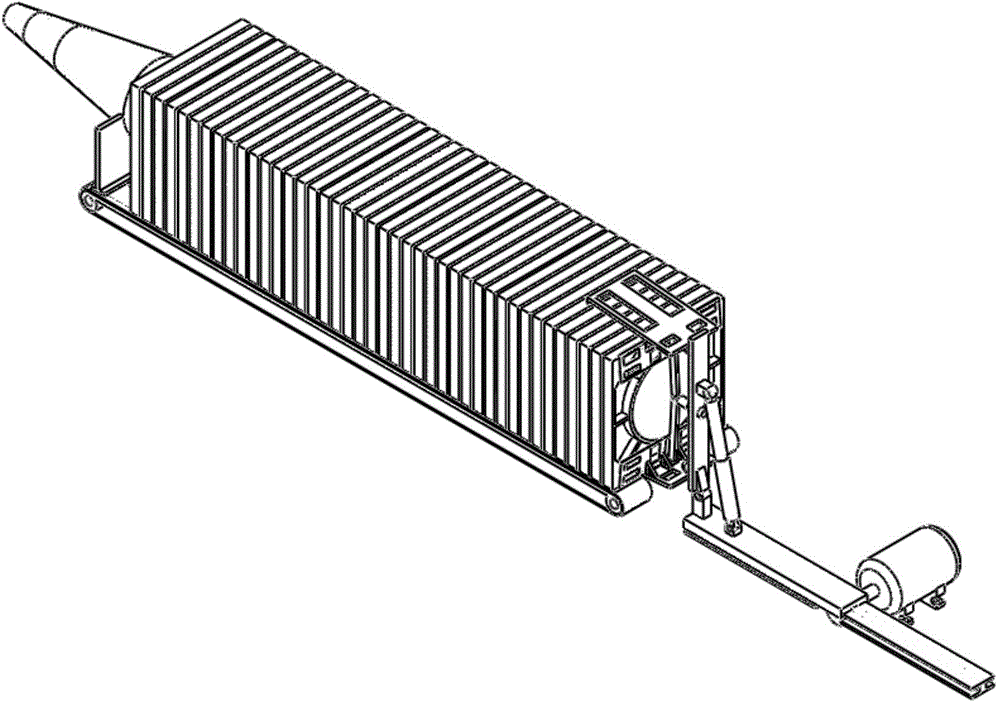

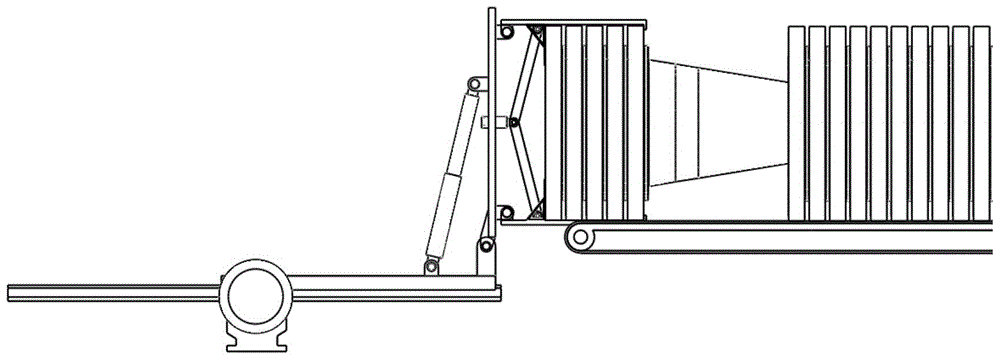

[0015] The present invention is a horizontally stacked road cone conveying mechanism for a traffic road cone vehicle, comprising a clamping plate 1, a support bracket 2, a connecting rod 3, a clamping hydraulic cylinder 4, a stepping motor 5, a vertical arm 6, and a base 7 , guide rail 8, gear 9, erecting hydraulic cylinder 10, clamping oil cylinder support 11, wherein, two clamping plates 1 are symmetrically arranged on the two ends of erecting arm 6, and are connected with the erecting arm 6 in rotation, clamping The oil cylinder support 11 is fixedly connected to the vertical arm 6 and is located in the middle of the two clamping plates 1, the clamping hydraulic cylinder 4 is fixedly connected to the clamping cylinder support 11, and the two connecting rods 3 are respectively connected to the clamping hydraulic cylinder 4 The output shaft and the clamping plates 1 on both sides are rotationally connected, and the two supporting brackets 2 are respectively fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com