Rotary type oily particle filling proportional valve

A rotary, quantitative valve technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of easy overflow, large particles easy to form blockage, easy to occur splashing, etc., to achieve improved sealing, simple structure, Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

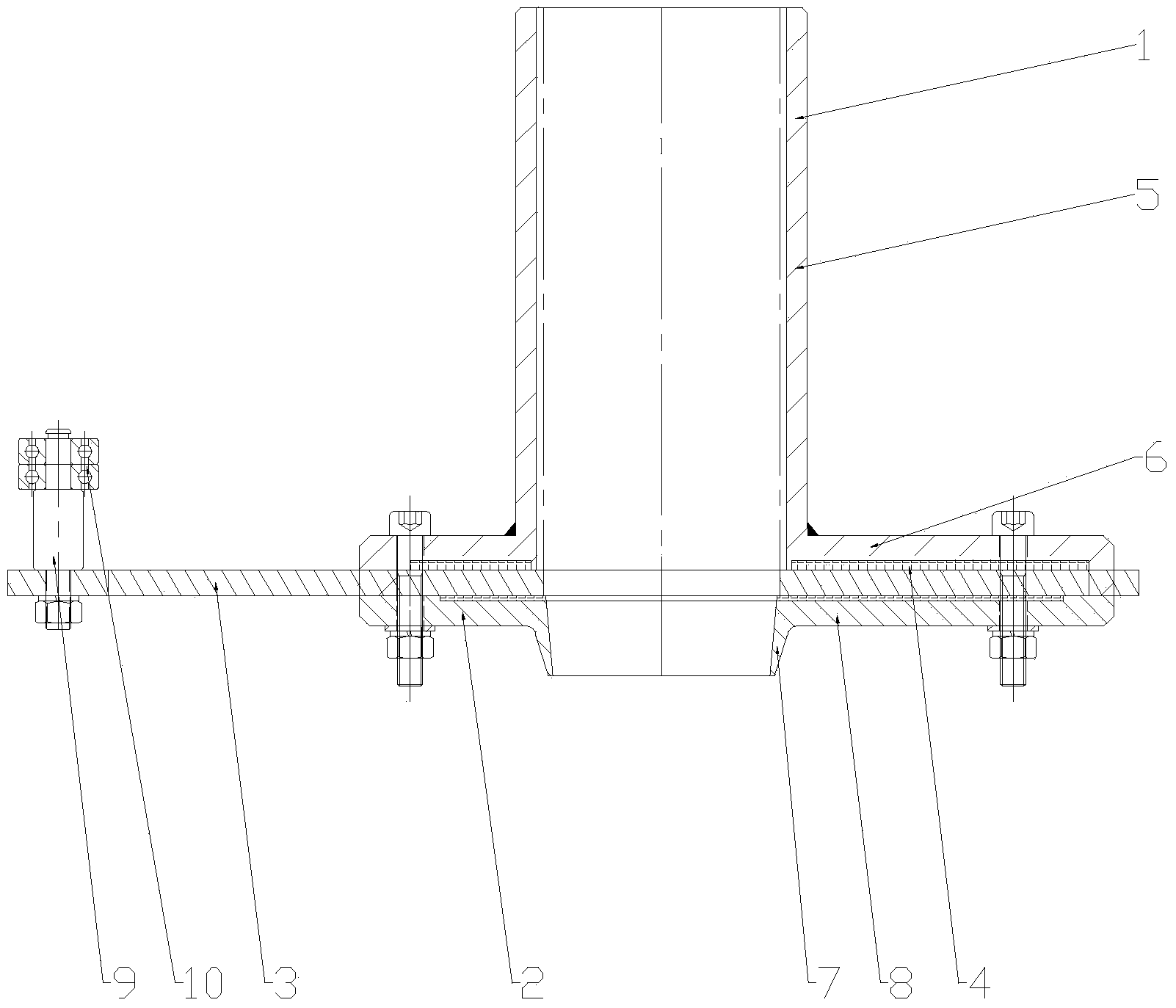

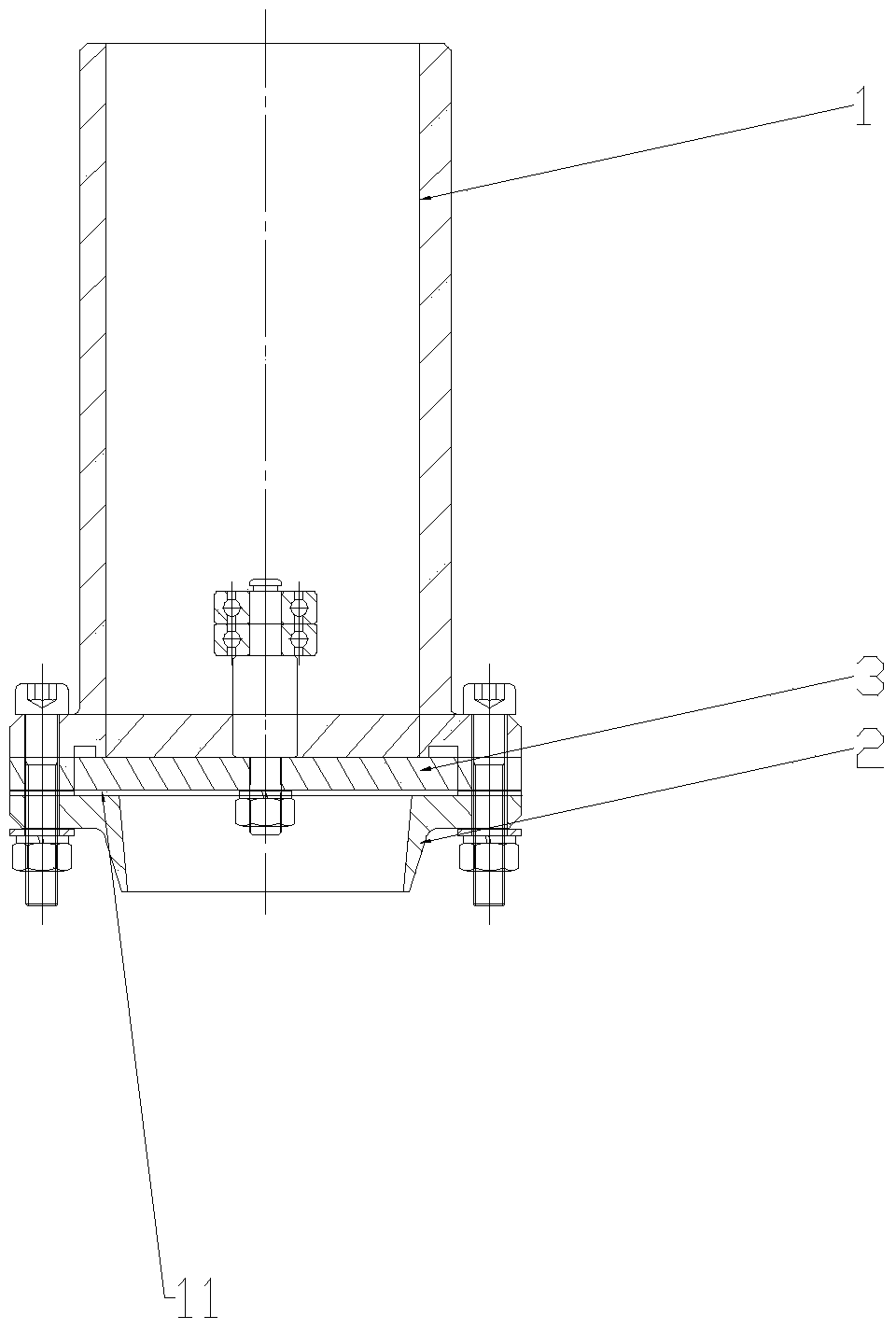

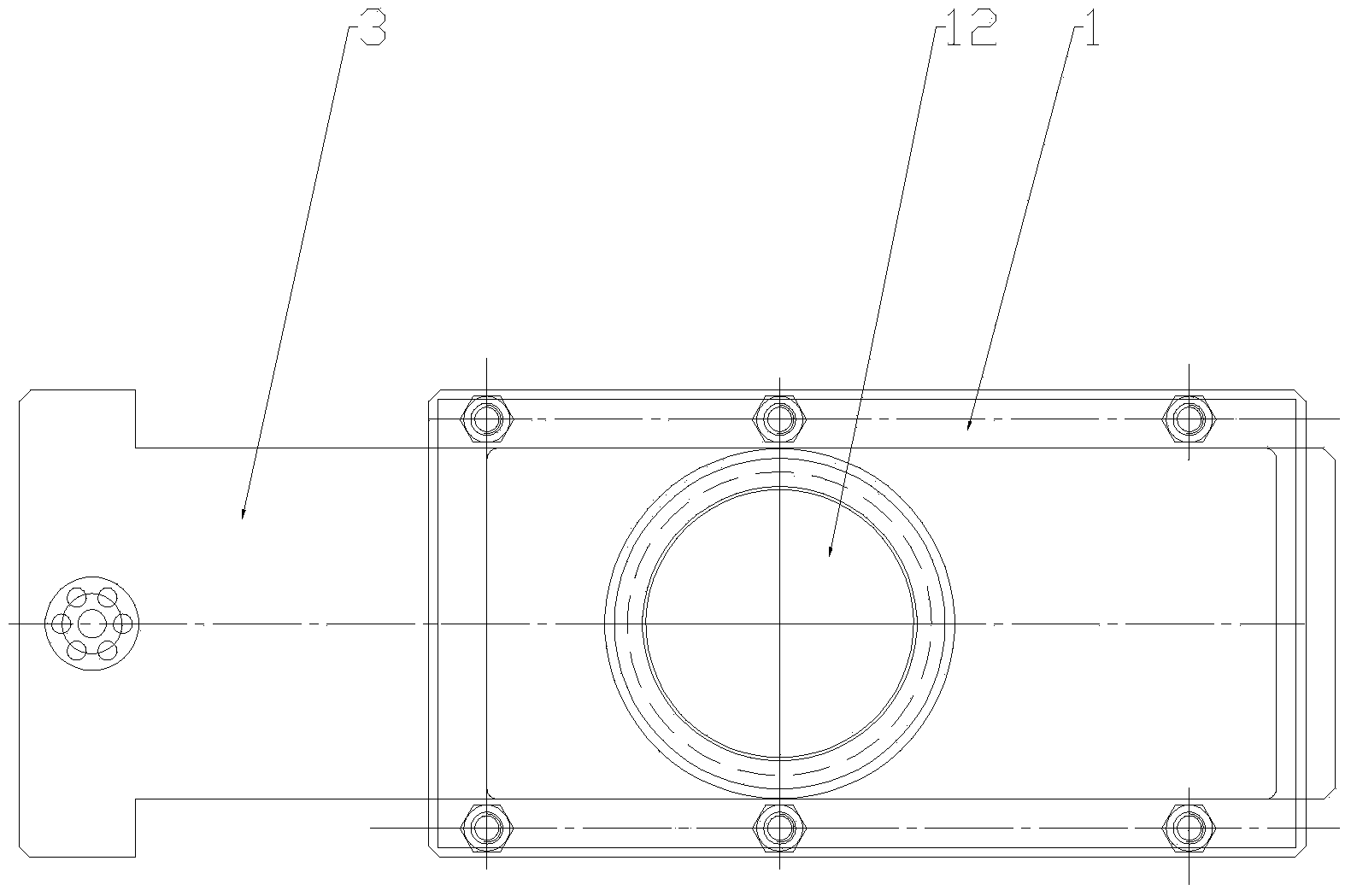

[0016] like Figure 1~3 As shown, the present invention mainly includes upper valve body 1, lower valve body 2, valve plate 3 and valve plate opening shaft 9, upper valve body 1 includes quantitative cup 5 and upper connecting plate 6, quantitative cup 5 and upper connecting plate 6 up and down connected into one. The dosing cup 5 is provided with a cylindrical material accommodating chamber that penetrates up and down. The diameter and height of the material accommodating chamber in the dosing cup is calculated according to the amount of each bottle of food to be filled. When filling, the sauce in the dosing cup 5 is just right. Capable of filling a filling bottle without material spillage.

[0017] The lower valve body 2 includes a lower connecting plate 8 and a feeding port 7, and the lower connecting plate 8 and the feeding port 7 are connected u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap