Suspended filling material used for sewage processing

A technology for suspended fillers and sewage treatment, applied in the field of suspended fillers and suspended fillers for sewage treatment, can solve the problems that suspended fillers are not easy to hang film, not easy to suspend, etc., and achieve the effect of uniform distribution and high-efficiency treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

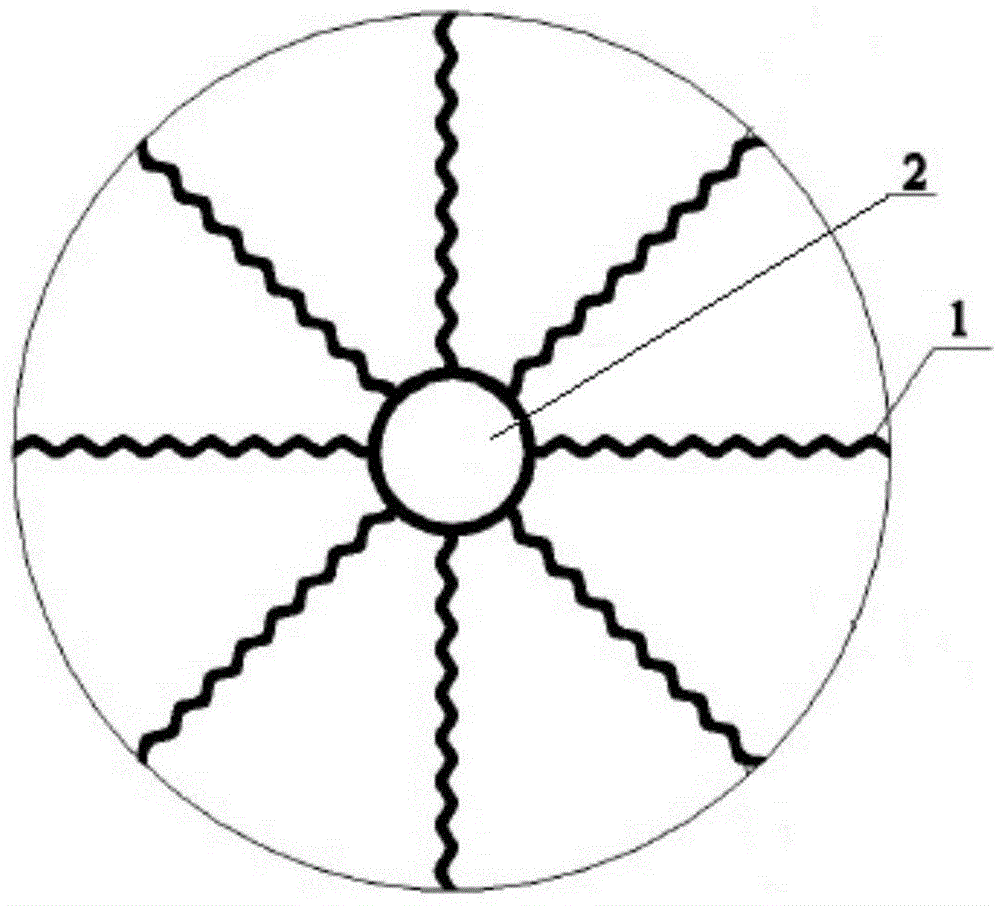

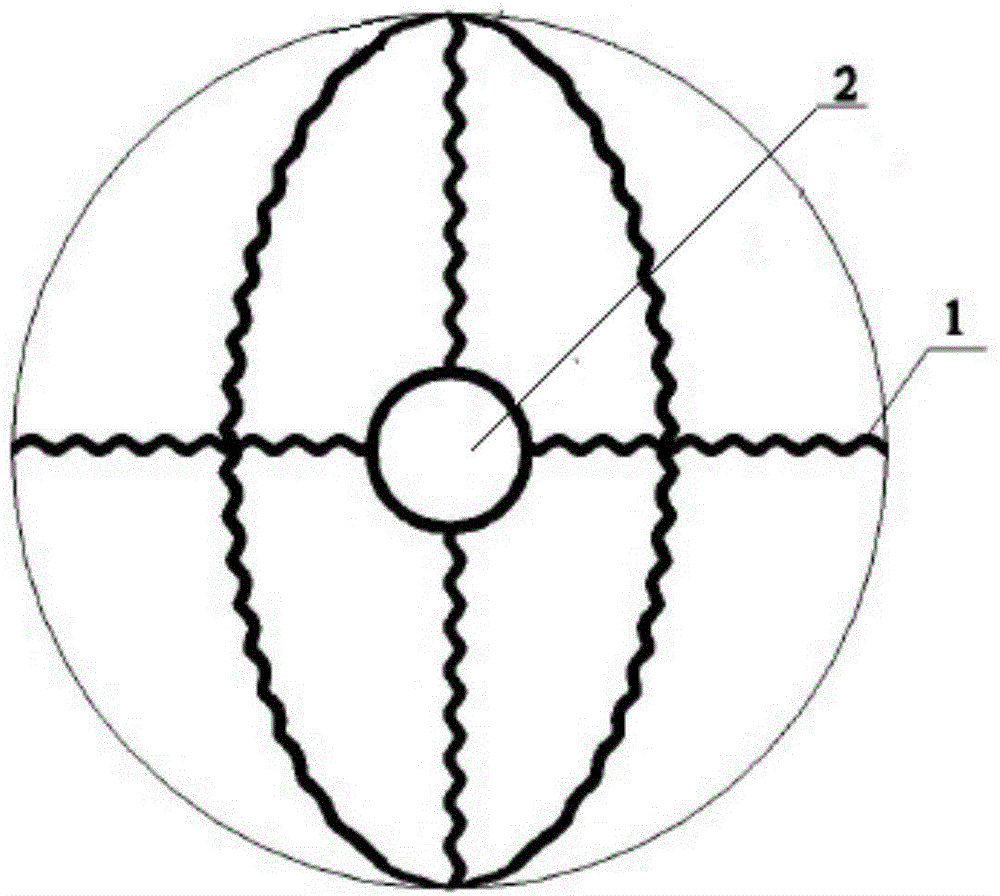

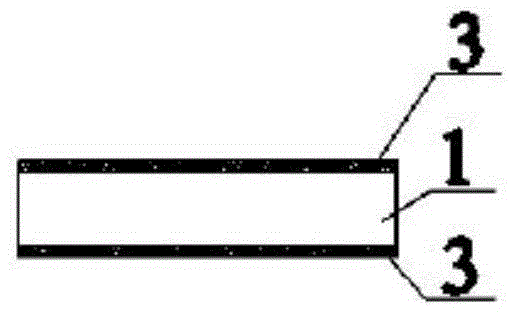

[0039] Suspended filler for sewage treatment, the overall shape is spherical, with a modified coating on the surface, the diameter is 10-60mm, and it is integrally injection molded. The material of the suspended filler is lightweight anti-corrosion material, in this embodiment, it is high-density polyethylene. Suspended packing includes packing sheet 1 and packing core 2. Filling sheet 1 is a semi-annular thin sheet with a diameter of 10-60 mm and a thickness of 0.5-1.5 mm. Filling core 2 is a hollow sphere, the surface layer is sealed with high-density polyethylene, and the interior is hollow. The thickness of the surface layer is 0.5-1.5 mm, and the packing sheet 1 is arranged symmetrically and radially in the three-dimensional space around the packing core 2. The packing sheet 1 and the packing core 2 are arranged concentrically and the inner diameter of the packing sheet 1 is equal to the outer diameter of the packing core 2. The surface of the filler is treated with modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com