Dam bag mounting construction method for inclined wall type rubber dam

A construction method and rubber dam technology, which is applied in the fields of municipal engineering, water conservancy and hydropower, can solve problems such as the easy deviation between the center line of the dam bag and the dam axis, the slow movement of the winch equipment group, and the slow deployment of the dam bag, so as to shorten the construction period and ensure the deployment Flatness, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

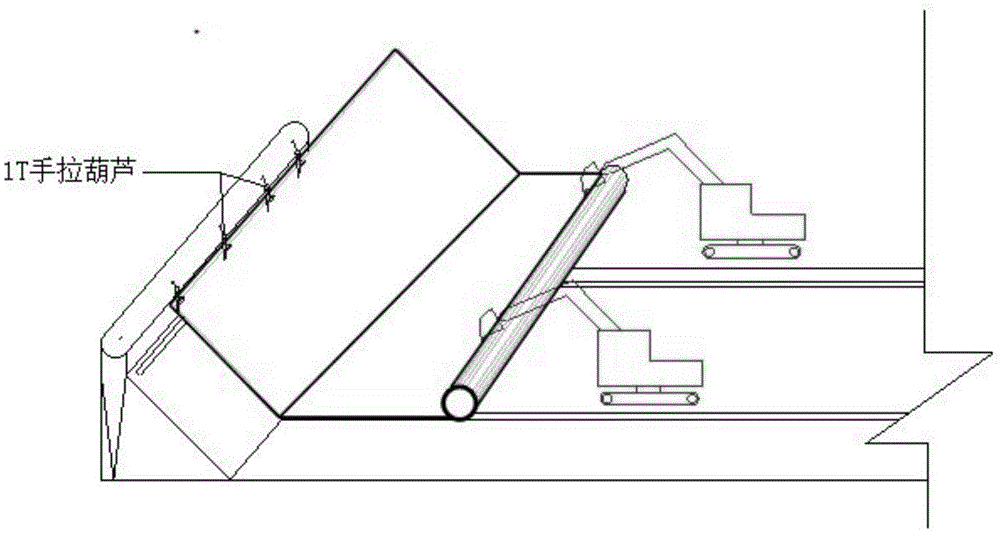

Image

Examples

Embodiment Construction

[0010] Now in conjunction with accompanying drawing this patent is described further:

[0011] 1. Embedded anchor bolts

[0012] Stake out according to the design and construction drawings, and the hooks at the bottom of the bolts provided are welded together with the erecting bars and reinforcements embedded in the dam bottom plate. The threaded part of the bolt is protected by wrapping with plastic film.

[0013] 2. Anchor bolt correction, floor inspection

[0014] (1) Correct the verticality of the bolts.

[0015] (2) The sharp corners of the inner side of the upper and lower anchor grooves, the concrete, cement slurry adhered to the bottom plate, the contact surface of the pier and the dam bag are all polished by a grinder, and the obvious sharp corners are polished into rounded corners, protruding, The burrs are completely removed.

[0016] (3) In order to ensure the combination of the anchor concrete and the anchor groove concrete, the concrete anchor contact surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com