Pilot production wellhead platform aiming at complex oil pools

A platform and trial production technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as difficult to accurately determine oil reservoir reserves, difficult to guarantee the rate of return on capital, and increased exploration difficulty, so as to reduce capital investment and risks, reduce construction costs, and control the effects of development risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

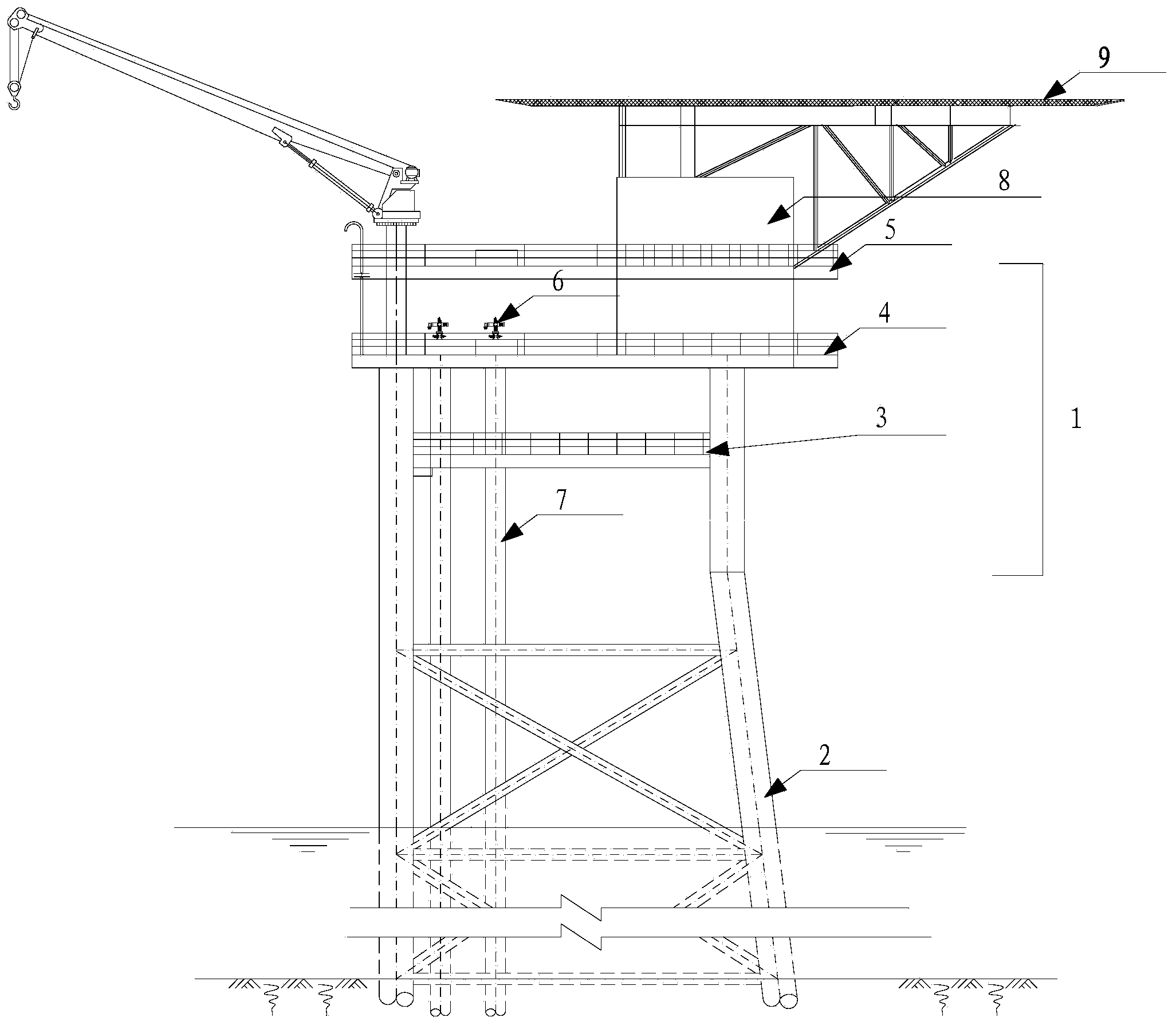

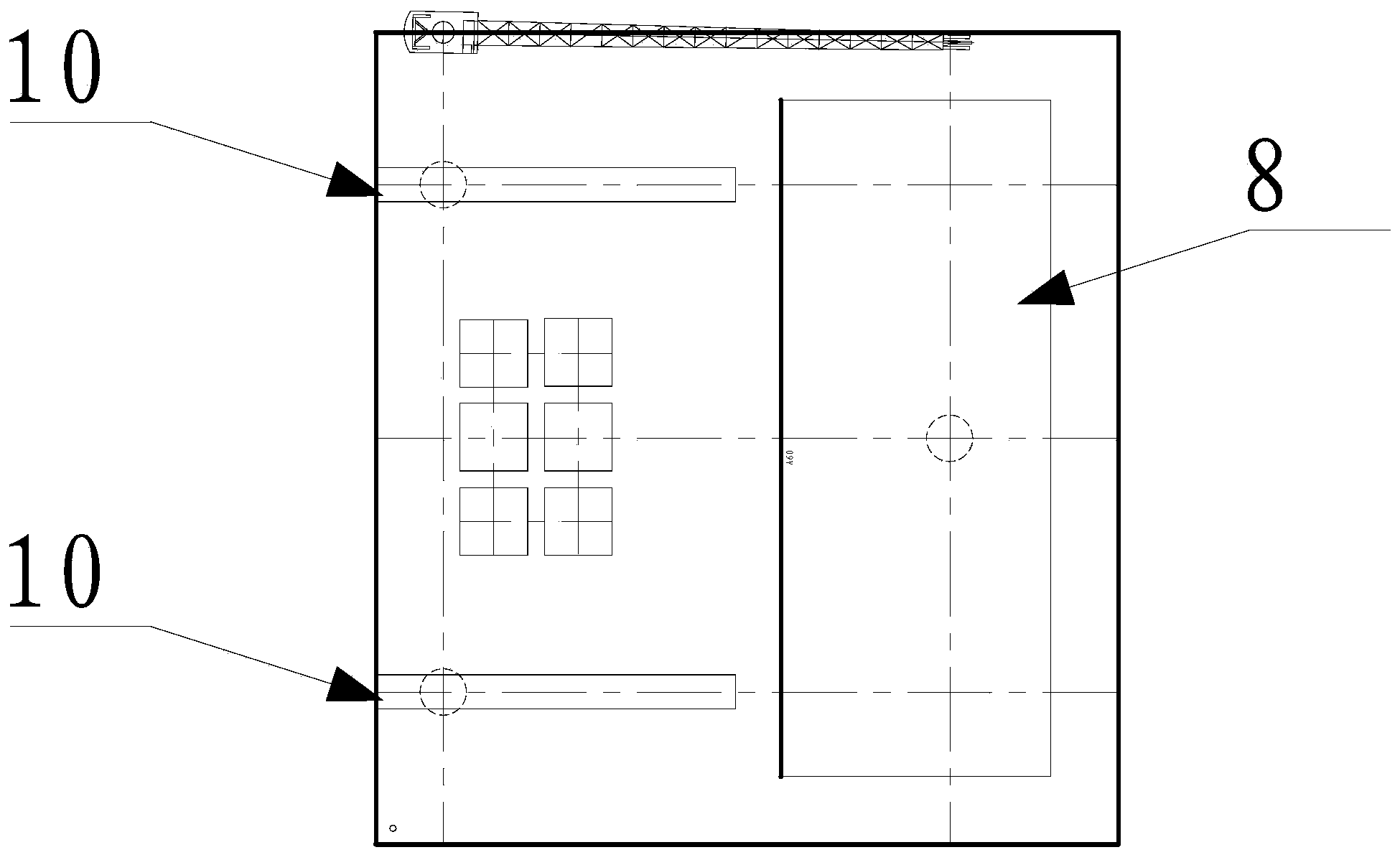

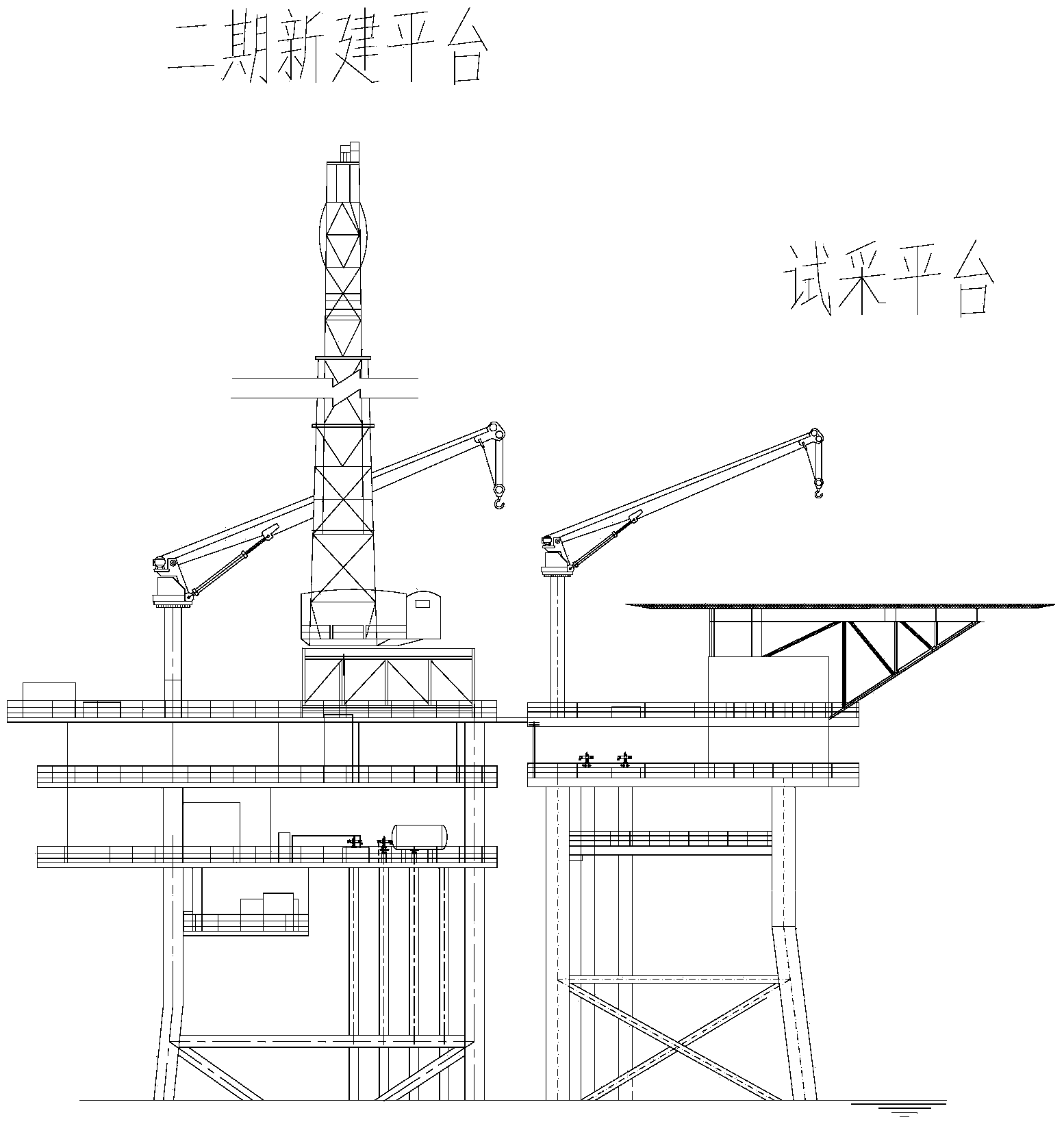

[0025] Such as figure 1 with figure 2 As shown, the test wellhead platform provided by the present invention is a steel fixed jacket platform, and the platform is suitable for a three-leg wellhead platform with 3 legs, 3 main piles, and 6 well slots within a water depth of 40m. The test production wellhead platform of the present invention comprises an upper block 1, three platform leg columns 2 and three steel pile foundations. Among them, the upper block 1 is a steel truss structure, and the upper block 1 includes the main deck 3, the production deck 4 and the drilling deck 5 arranged in sequence from bottom to top, and the upper end of the platform leg column 2 is connected with the main deck 3. The pile foundation runs through the platform leg column 2 and extends beyond the platform leg colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com