High temperature mine ventilation method

A technology of mine ventilation and ventilation mode, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc. It can solve the problems of unfavorable mine cooling, complex ventilation network, and insufficient ventilation capacity, and achieve the effect of alleviating high temperature heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

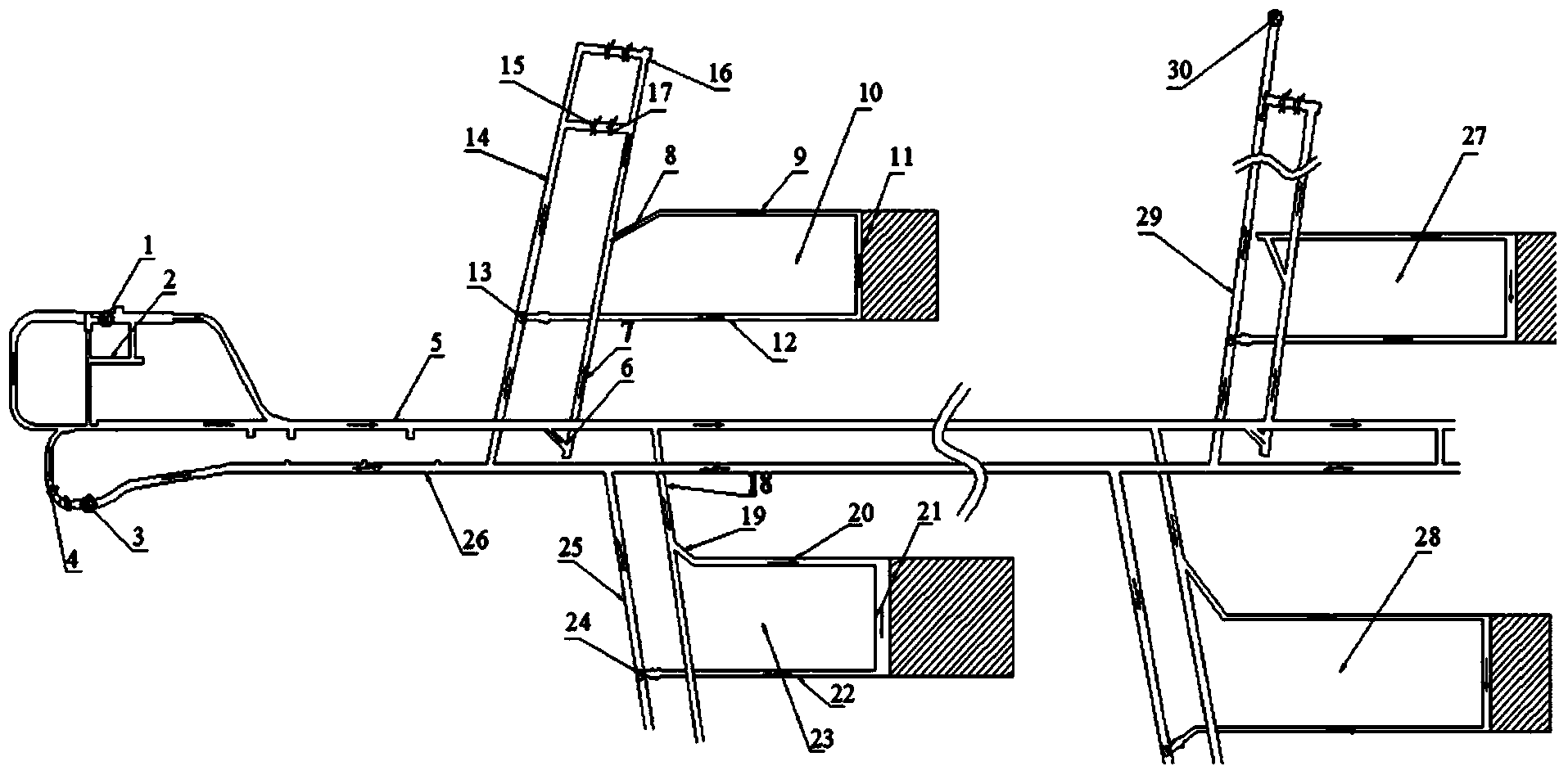

[0024] Such as figure 1 As shown, the fresh wind enters the downhole from the air inlet shaft 1 (auxiliary shaft), enters the underground concentrated air intake lane 5 through the parking lot at the bottom of the shaft, passes through the initial uphill mining area 10 and the lower parking lot 6, enters the initial uphill mining area into the upper mountain 7, and passes through The central parking lot 8 of the initial uphill mining area enters the air inlet level lane 9 of the coal mining face of the initial uphill mining area, enters the return air level lane 12 of the coal mining face of the initial uphill mining area through the working face 11, and enters the return air level lane 14 of the initial uphill mining area , into the concentrated return air alley 26, and finally return to the ground through the air shaft 3 in the central square; at the same time, the fresh air flow enters the initial downhill mining area from the centralized air intake alley 5 into the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com