Conveying chain plate of vegetable dehydrating device

A conveyor chain plate, vegetable dehydration technology, applied in the direction of drying solid materials, applications, food processing, etc., to achieve the effect of improving efficiency and easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

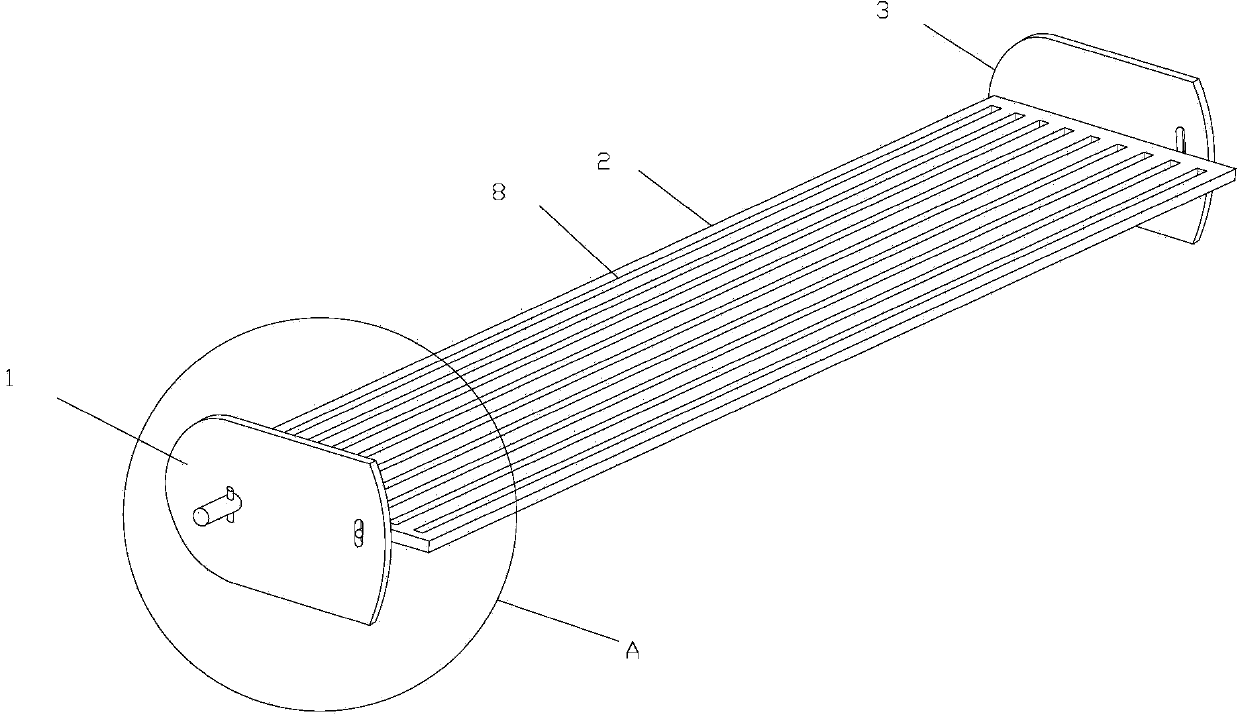

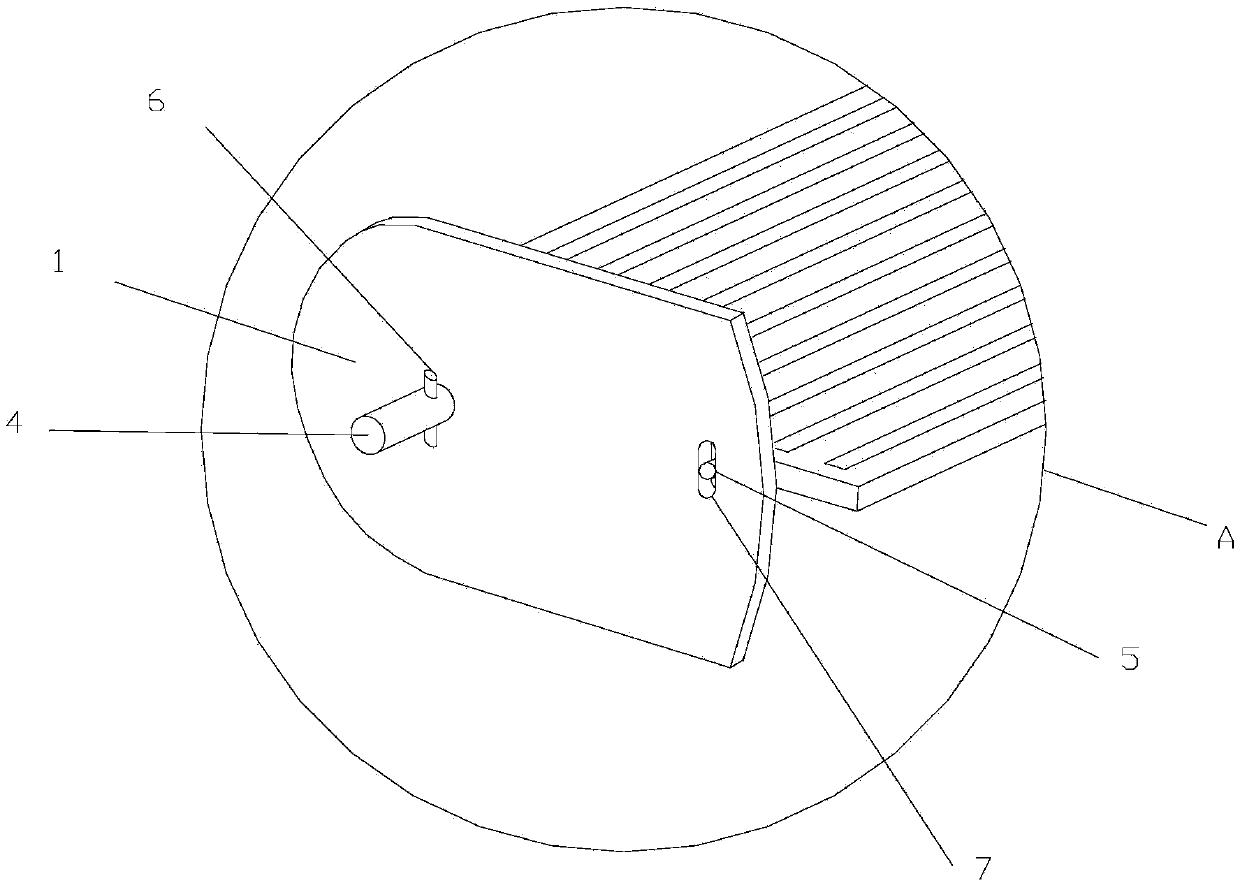

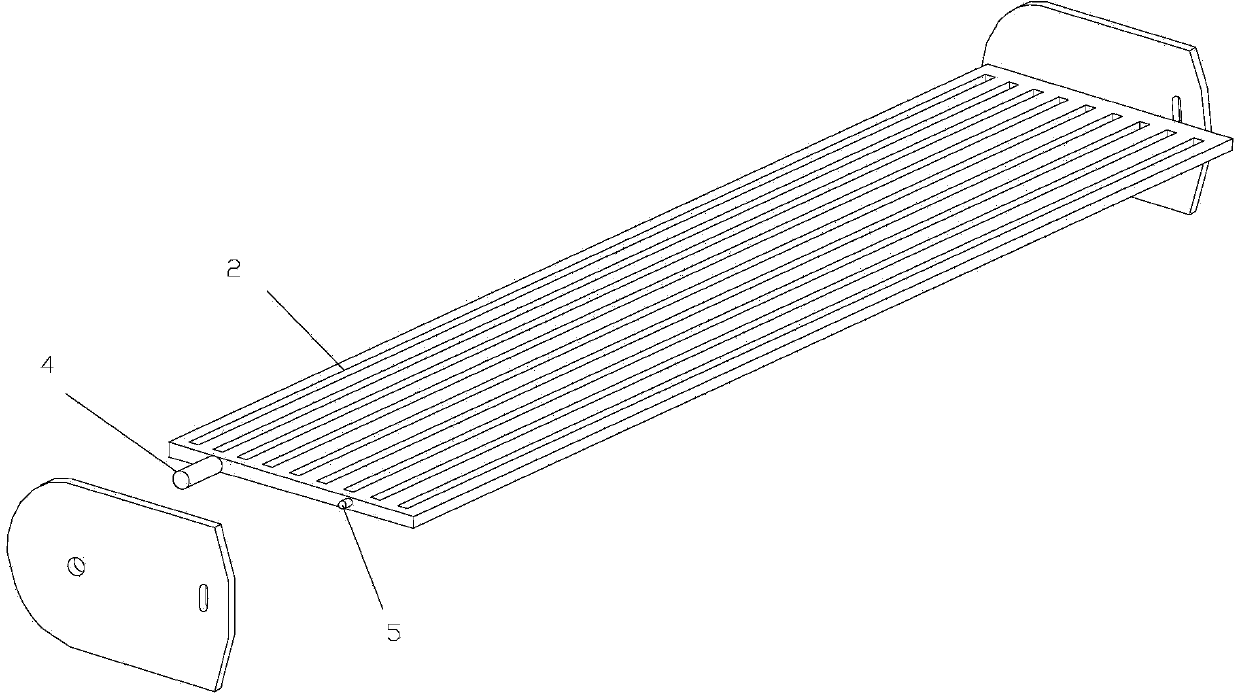

[0020] Such as figure 1 , 2 As shown in , 3, the conveying chain plate of a vegetable dehydration device described in this embodiment includes a side plate 1, the rear end of which is an arc-shaped end 3, and a conveying plate 2 is arranged between two side plates 1, The two ends of described conveying plate 2, rear portion is provided with chain connecting rib 4, and front end is provided with clamping rib 5, and described side plate 1 is provided with arc groove 7, and described chain connecting rib 4 passes through side plate 1 and A limit pin 6 is provided on the exposed section, and the clamping rib 5 is movably arranged in the arc-shaped groove 7 ; a ventilation slot 8 is provided on the conveying plate 2 . Among them; the connecting rib 4 and the clamping rib 5 can be welded on the conveying plate 2 .

[0021] The conveyor chain plate of the vegetable dehydration device described in this embodiment is provided with a ventilation slot 8 on the conveyor plate 2. The ve...

Embodiment 2

[0025] Such as Figure 4 As shown, the conveying chain plate of the vegetable dehydrating device described in this embodiment is different from Embodiment 1 in that: the conveying plate 2 is formed by connecting two wave plates 9 up and down with an intermediate plate 10, and the intermediate plate 10 is Gaps 11 are provided at equal intervals, and the wave plate 9 is formed by alternately arranging plane sections 91 and arcuate sections 92. The holes 12 , the ventilation slots 8 and the ventilation holes 12 communicate with the gap 11 on the middle plate 10 .

[0026] In this embodiment, the middle plate 10 can be a hard plastic plate, and the corrugated plate 9 can be a sanitary stainless steel plate or a hard plastic plate. Of course, the material can be used, and is not limited to the method disclosed in this embodiment.

[0027] Since the wave plate 9 is provided, the wave plate 9 has a protruding arc surface section 92, so that the vegetables are placed on the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com