Determination method of steam turbine generator unit exhaust enthalpy

A technology for turbogenerators and turbogenerators, applied to measuring devices, measuring heat, instruments, etc., can solve problems such as the inability to calculate exhaust steam enthalpy, difficult on-line monitoring of steam turbine thermal tests, lack of turbogenerators, etc. Achieve the effect of convenient online monitoring, meeting engineering needs, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

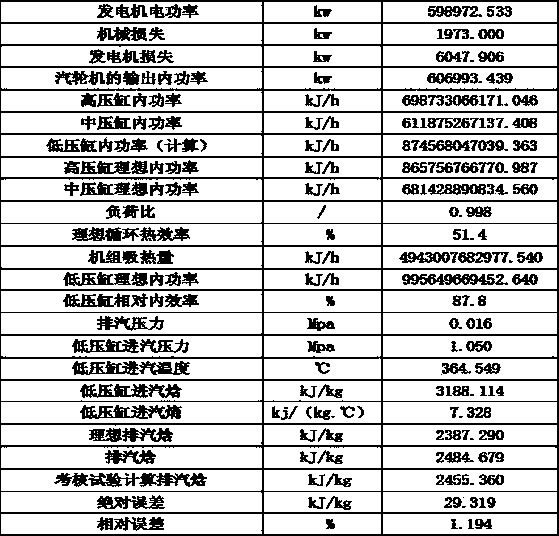

[0053] Detection example: NZK600-24.2 / 566 / 566 supercritical, three-cylinder four-exhaust, one-time intermediate reheat, single-shaft, direct air-cooled steam turbine generator set was tested, and its effective parameters are mainly steam pressure and temperature It is 24.2MPa, 566°C; the reheating temperature is 566°C.

[0054] The exhaust enthalpy of the turbogenerator unit is determined according to the following method, and the detection data and test results are shown in Table 1.

[0055] Step 1: Calculation of the power in the low-pressure cylinder of the turbogenerator.

[0056] A: Read the electric power of the turbogenerator, and calculate the mechanical loss of the turbogenerator according to the mechanical efficiency of the turbogenerator ( △P m ), according to the turbogenerator loss curve to read the turbogenerator power generation loss ( △ P g ), according to the formula (1) to calculate the output internal power of the turbogenerator ( P i ),

[0057] P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com