Test device and method for monitoring dynamic micro-friction state of steel wire rope-friction lining

A friction lining and test device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of inability to investigate the dynamic micro-friction behavior of steel wire ropes, and can not explore the dynamic micro-friction behavior, etc., to achieve wide practicability and functionality Complete and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

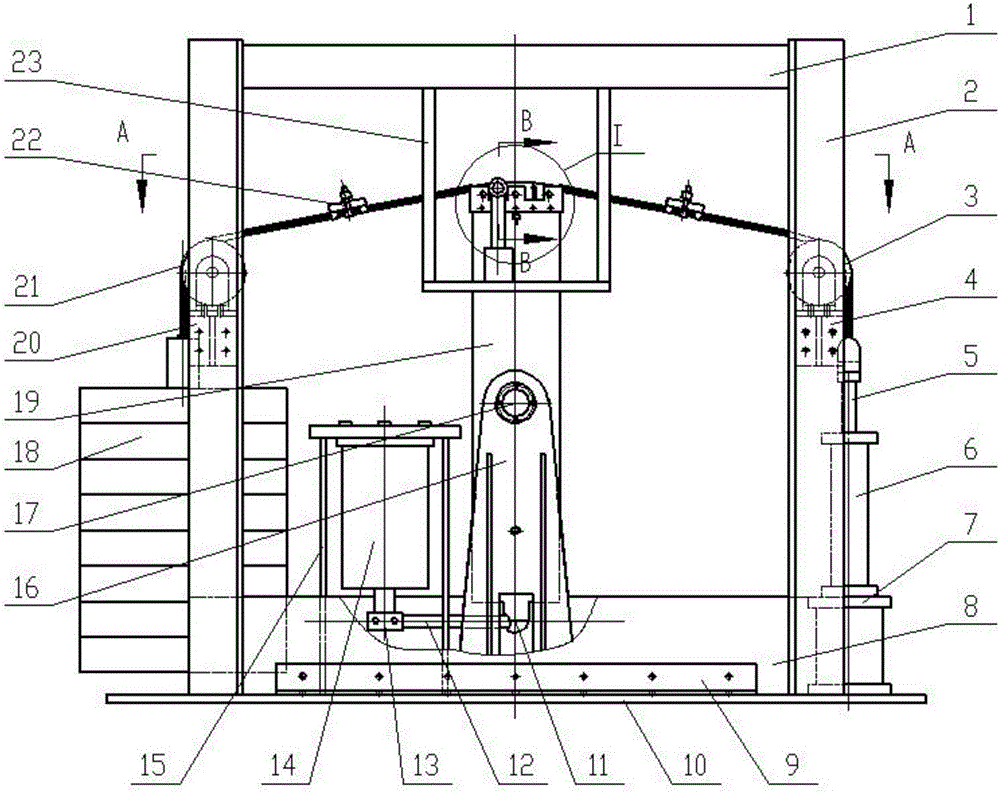

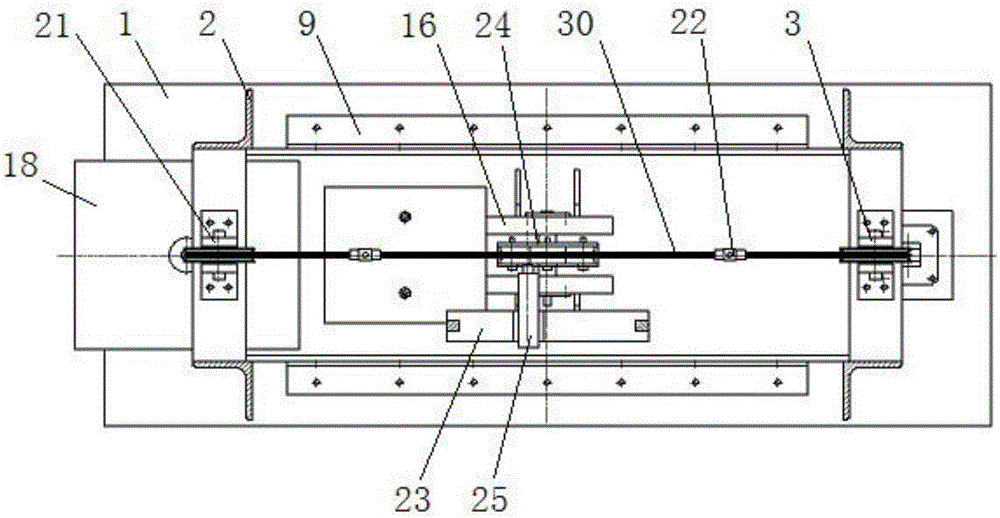

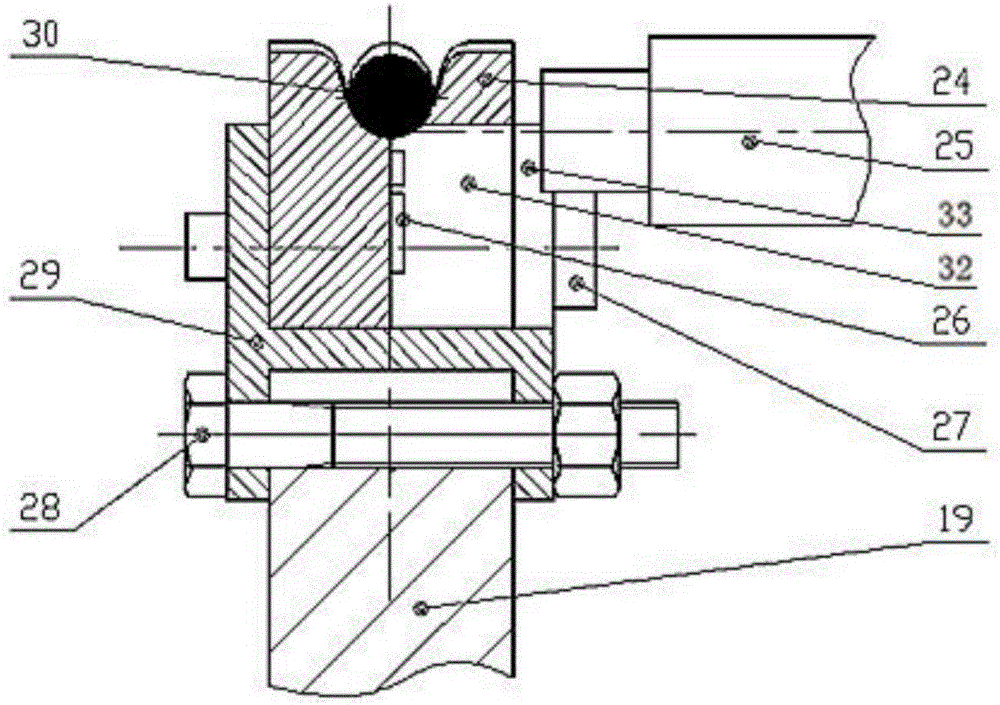

[0024] Such as Figures 1 to 4 As shown, a test device for monitoring the dynamic micro-friction state of the steel wire rope-friction lining of the present invention includes a base frame, a loading system, a micro-slip system and a state monitoring system.

[0025] Described pedestal comprises base plate 10, the support column 2 that is symmetrically arranged on the two ends of base plate 10, the bottom beam 8 that is arranged on the bottom of support column 2, the fixed angle steel 9 that is arranged between support column 2 bottom and base plate 10 and is fixed on support column 2 Load beam 1 at the top.

[0026]The loading system includes a weight loading system, a hydraulic loading system and a wire rope 30 . The heavy block loading system includes an A pulley bracket 20 arranged on the support column 2, an A pulley 21 fixed on the A pulley bracket 20, and a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com