High-precision analog-to-digital converter and analog-to-digital conversion method

An analog-to-digital converter and analog-to-digital conversion technology, applied in the direction of analog-to-digital converters, etc., can solve the problem that the conversion accuracy of integral A/D converters is difficult to further improve, shorten the required time, avoid measurement errors, and solve Effect of Conversion Precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, a high-precision analog-to-digital converter.

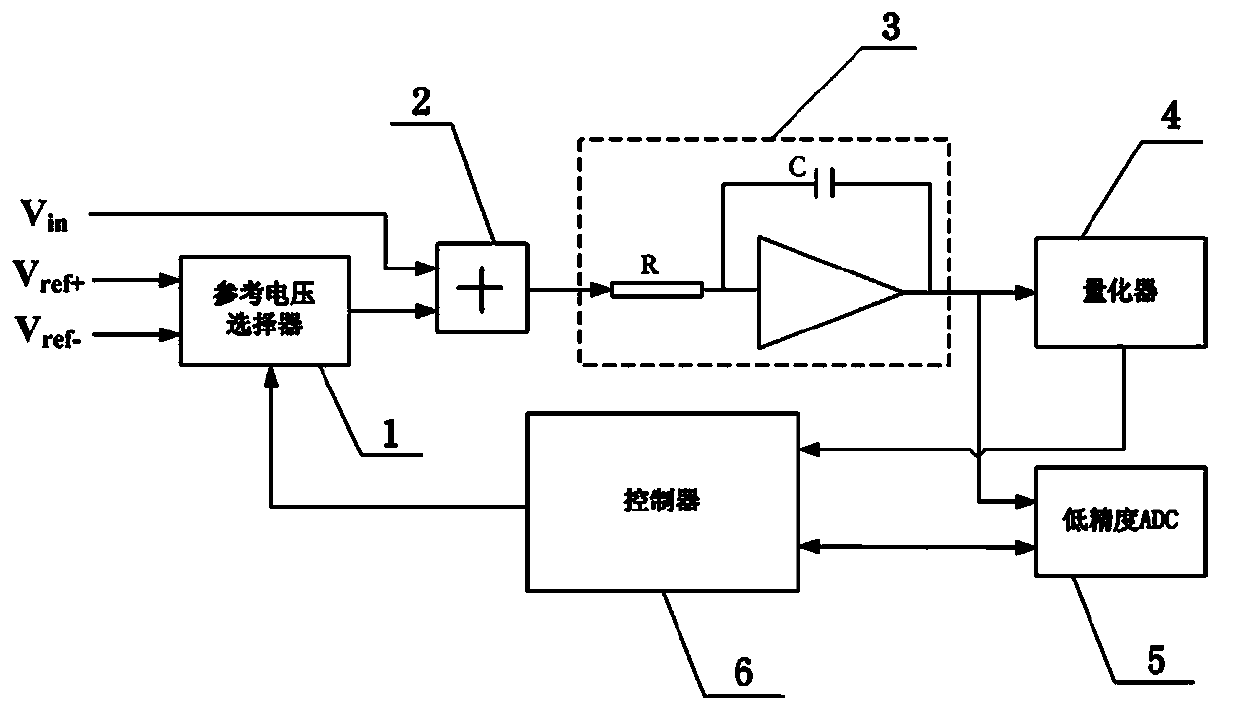

[0053] Such as figure 1 As shown, the high-precision analog-to-digital converter provided by the present invention includes a reference voltage selector 1 , a summer 2 , an integrator 3 , a quantizer 4 , a low-precision A / D converter 5 and a controller 6 .

[0054] The reference voltage selector 1 is respectively connected to the summer 2 and the controller 6, and under the control of the controller 6, it selectively outputs a positive reference voltage V ref+ signal or negative reference voltage V ref- Signal. Positive reference voltage V ref+ signal or negative reference voltage V ref- The signal is used to adjust the voltage signal output by the integrator 3, so that the voltage signal output by the integrator 3 will not reach a saturation state and maintain the charge balance of the integrating capacitor. The reference voltage signal output by the reference voltage selector 1 is sent to the summer 2 ...

Embodiment 2

[0084] Embodiment 2, a high-precision analog-to-digital conversion method.

[0085] refer to figure 1 , the high-precision analog-to-digital conversion method provided by the present invention is specifically: the reference voltage selector 1 selectively outputs the positive reference voltage V under the control of the controller 6 ref+ signal or negative reference voltage V ref﹣ signal, the positive reference voltage V ref+ signal and negative reference voltage V ref﹣ The signal is a reference voltage signal capable of regulating the output of the integrator 3, the positive reference voltage V ref+ and negative reference voltage V ref﹣ Satisfy the relation: |V in(max) |ref± |in(max) |, V in(max) is the maximum value of the input voltage, the reason for selecting the value range of the positive and negative reference voltages can be referred to the description in Embodiment 1; the positive reference voltage V ref+ signal or negative reference voltage V ref﹣ signal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com