Nanostructured stamp, embossing roller, and device and method for the continuous embossing of nanostructures

A technology of nanostructures and embossing rollers, which is applied to the nanostructured punches used for embossing embossing rollers, a kind of basis field, which can solve problems such as rising technical problems, and achieve the effect of simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

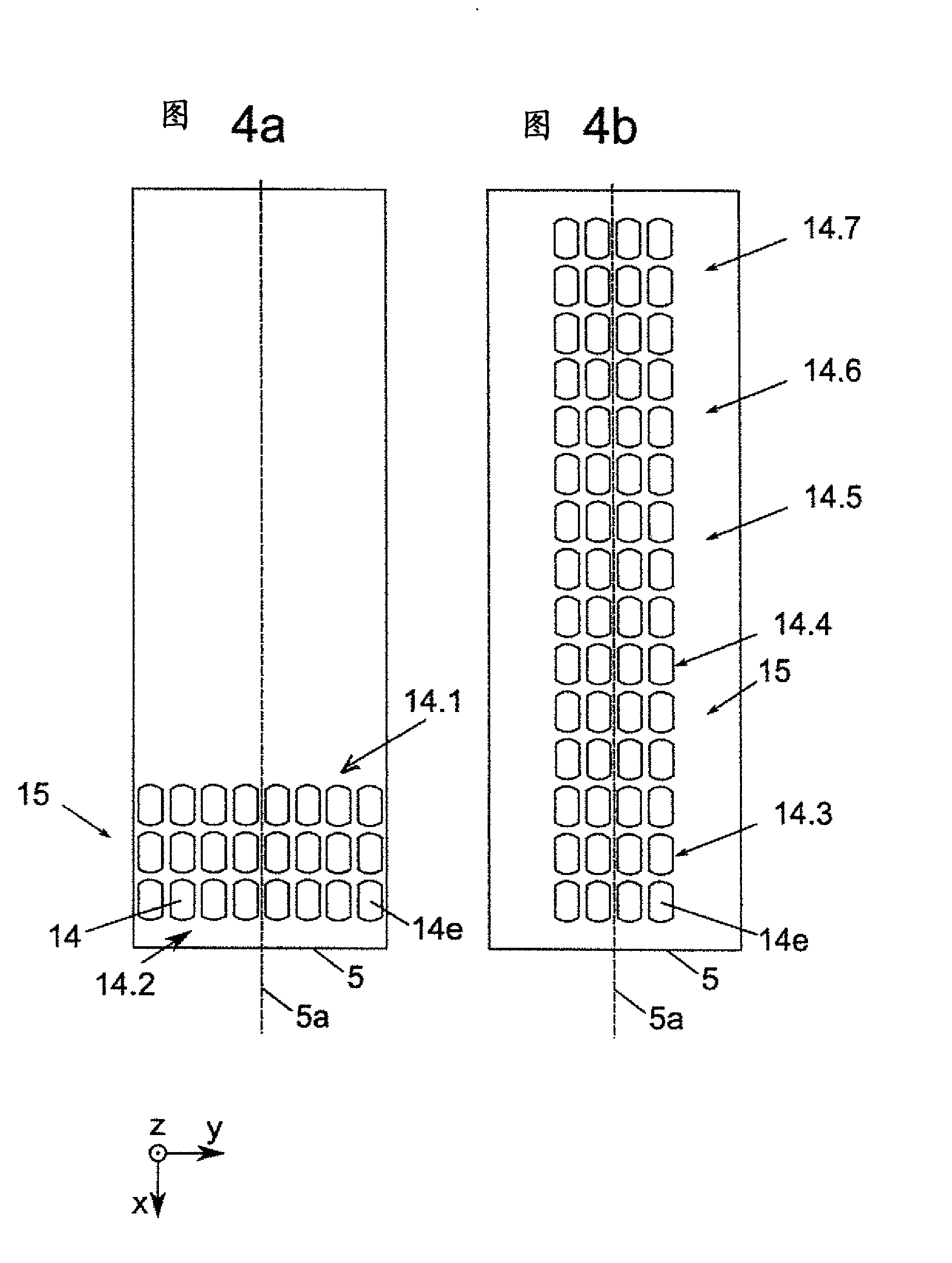

[0045] In the drawings, the features according to the invention are not shown to scale, in order to fully illustrate the function of the individual features. The proportions of the individual components are also partly not to scale, which can be traced in particular to the nanostructures 14 shown in a greatly enlarged manner. Nanostructures 14 , which are imprinted with the present invention or used to imprint corresponding nanostructures onto workpieces, are in the nanometer and / or micrometer range, whereas the order of magnitude of the machine components is in the centimeter range.

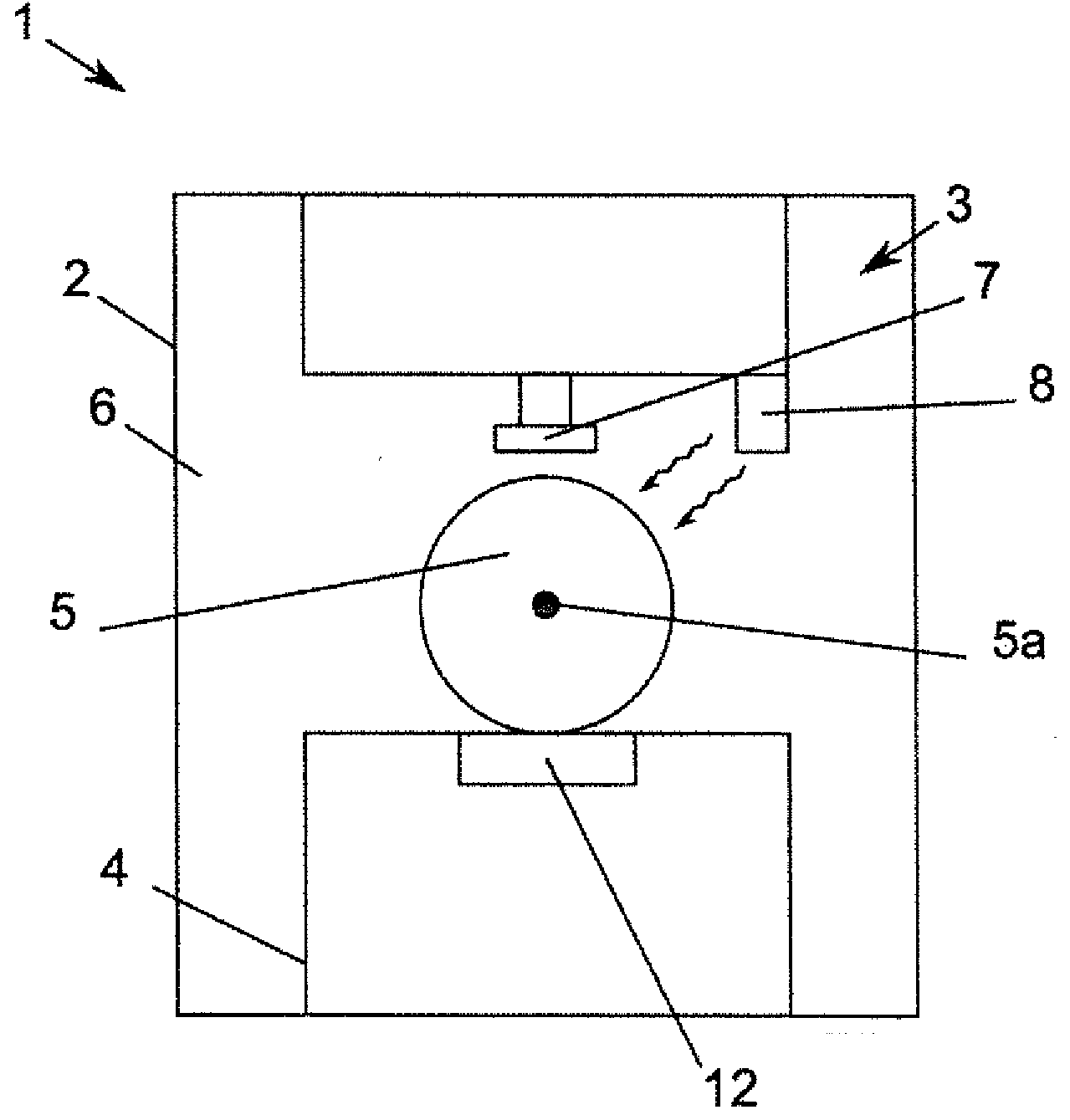

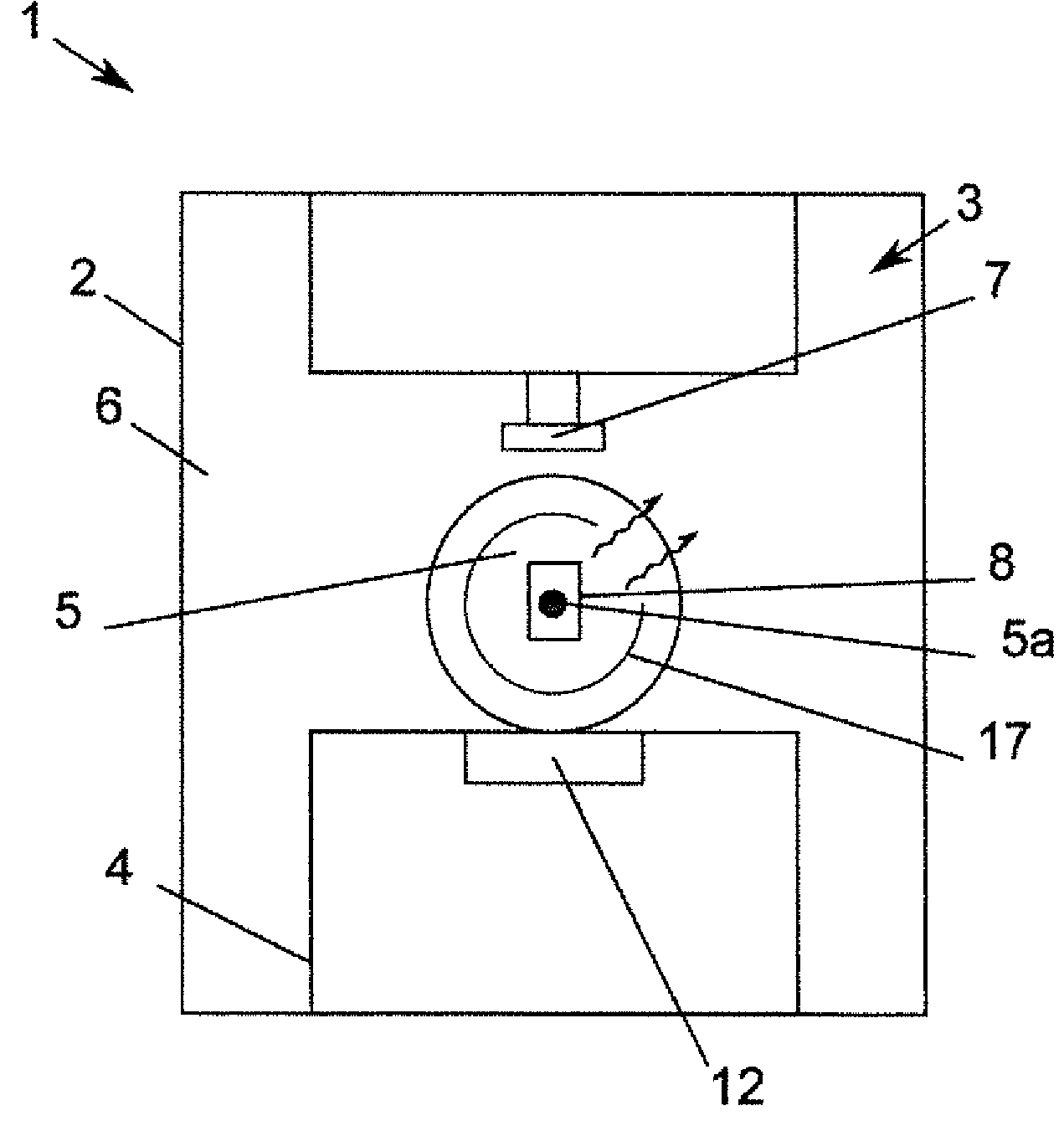

[0046] In FIG. 1 , a vacuum chamber 2 is shown schematically, which surrounds a working chamber 6 which can be subjected to a vacuum. The vacuum chamber 2 can be loaded via a not shown, sealed door or lock.

[0047] In the working chamber 6 , an embossing roller receptacle 4 is arranged on the bottom 2 b of the vacuum chamber 2 for receiving and controllably pivoting a rotary body 5 . The roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com