Method for enhancement of thermoelectric efficiency by the preparation of nano thermoelectric powder with core-shell structure

A core-shell structure and nano-powder technology, applied in the manufacture/processing of thermoelectric devices, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as increasing ZT value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

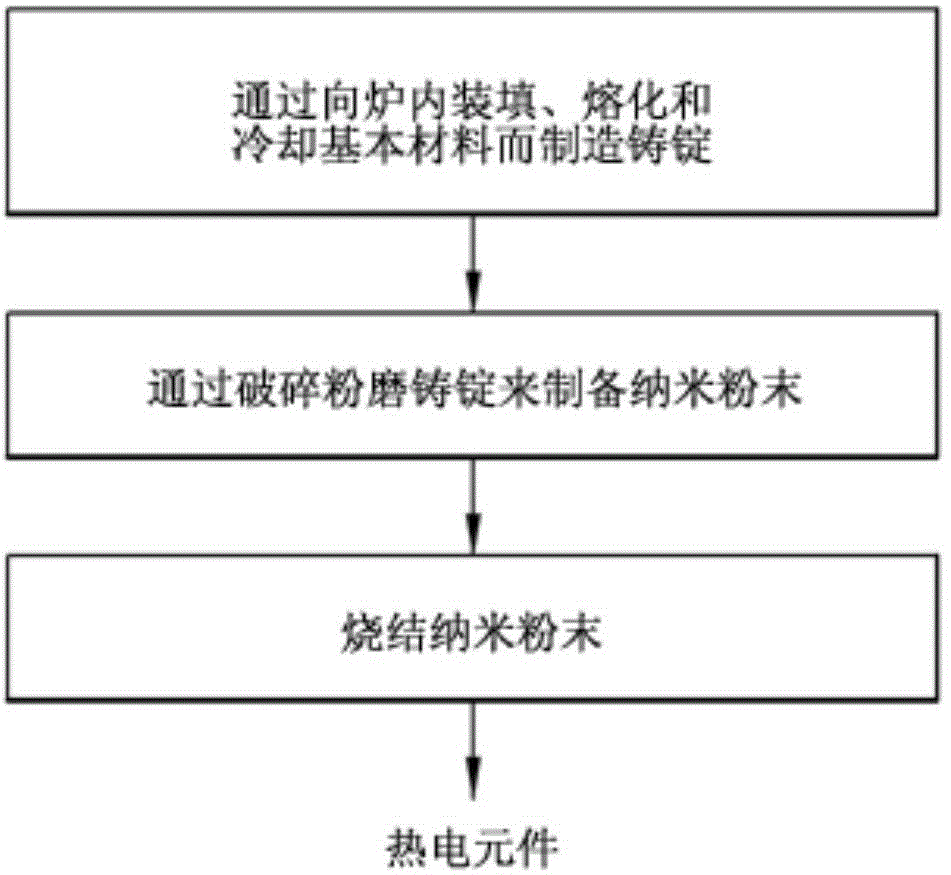

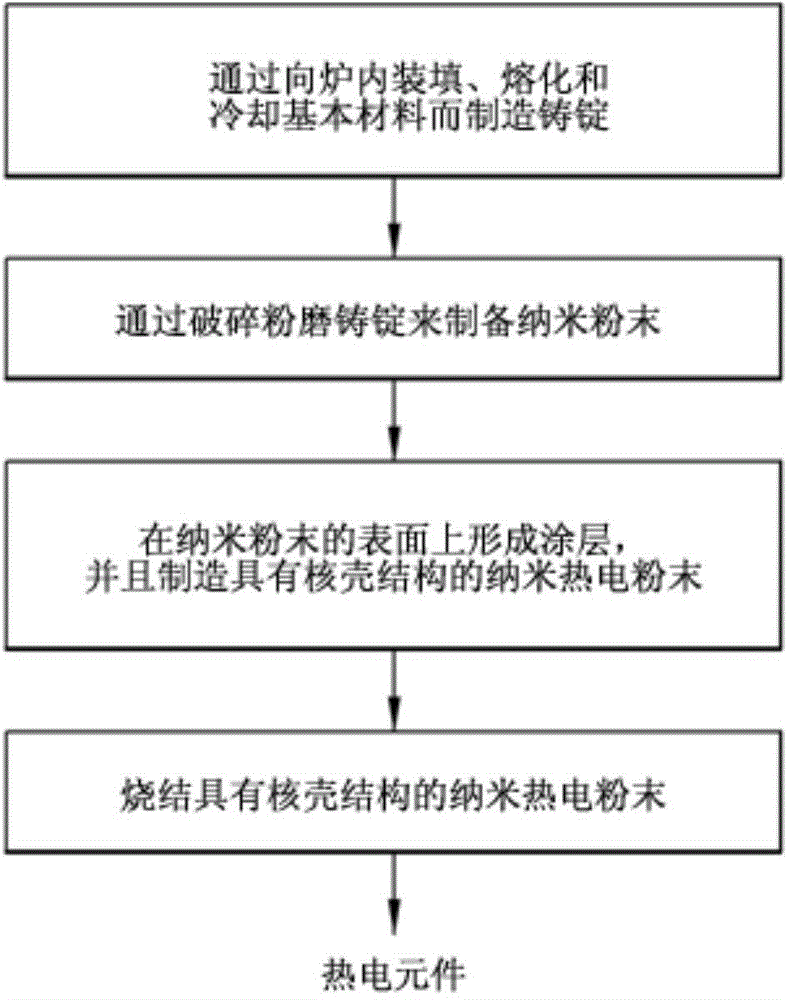

Method used

Image

Examples

Embodiment approach

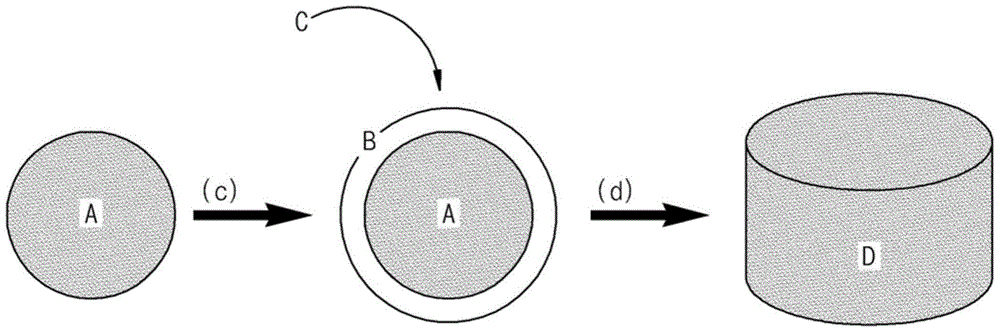

[0034] The present invention provides nano thermoelectric powder with a core-shell structure, which includes a coating on the surface of the nano powder, and by preparing the nano thermoelectric powder with the core-shell structure, the present invention can provide a thermoelectric element with enhanced thermoelectric efficiency.

[0035] The efficiency of a thermoelectric material can be defined by the following equation expressing the dimensionless ZT value.

[0036] ZT=S 2 σT / κ(S: Seebeck coefficient, σ: electrical conductivity, κ: thermal conductivity)

[0037] The ZT value is directly proportional to electrical conductivity and Seebeck coefficient, and inversely proportional to thermal conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com