Reversing atomization device

A technology of atomization device and steering device, which is applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of unfavorable workers' health, human energy consumption, etc., and achieve low power consumption and convenient operation , The effect of high atomization uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

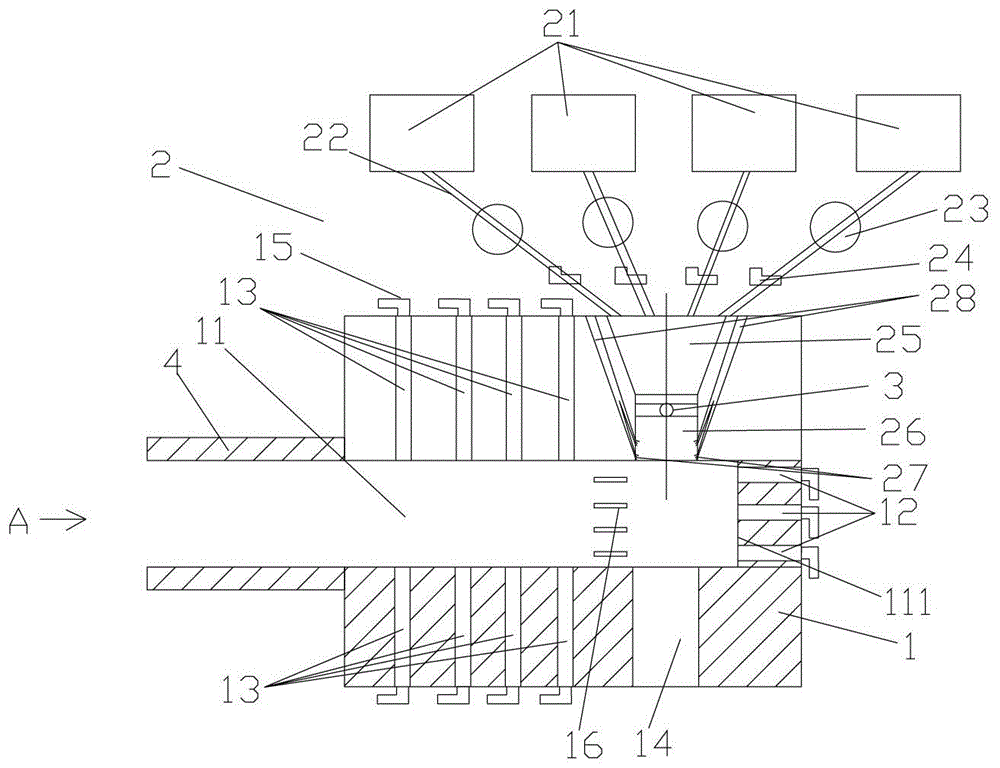

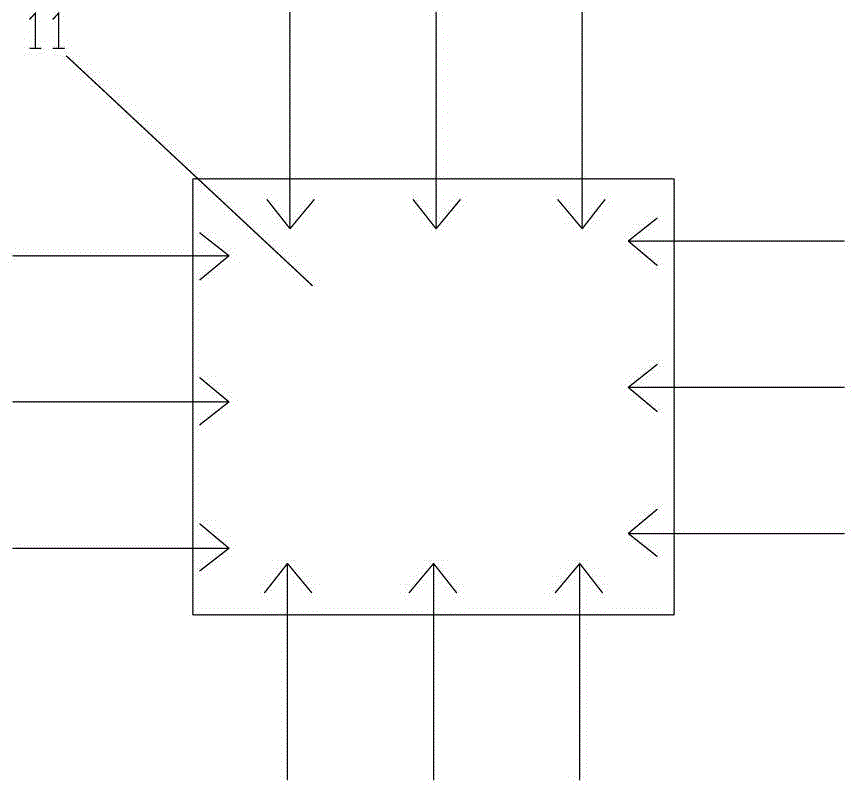

[0024] Such as figure 1 As shown, the present invention provides a direction-changing atomization device, which includes a body 1, a feeding device 2, a steering device and an atomization dispersion device. The body 1 has an atomization chamber 11 for material atomization and a material receiving device. The pipe quick connector; the atomizing dispersing device includes at least one air outlet channel 13, and the air outlet channel 13 is arranged on the upper and lower chamber walls of the atomization chamber 11 and on the side walls on both sides adjacent to the end wall 111, from The wind blown out by the air outlet duct 13 disperses the materials evenly. The direction-changing atomization device provided by the invention can fully atomize and disperse different types of polyurethane to obtain a suitable viscosity without manual operation, is environmentally friendly, and can control the viscosity of materials to a relatively accurate range.

[0025] The feeding device 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com