Nano indium sulfide photocatalyst as well as preparation method and application thereof

A technology of photocatalyst and indium sulfide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and preparation of organic compounds, which can solve the problems of low catalytic efficiency, achieve high photocatalytic activity, simple preparation method, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

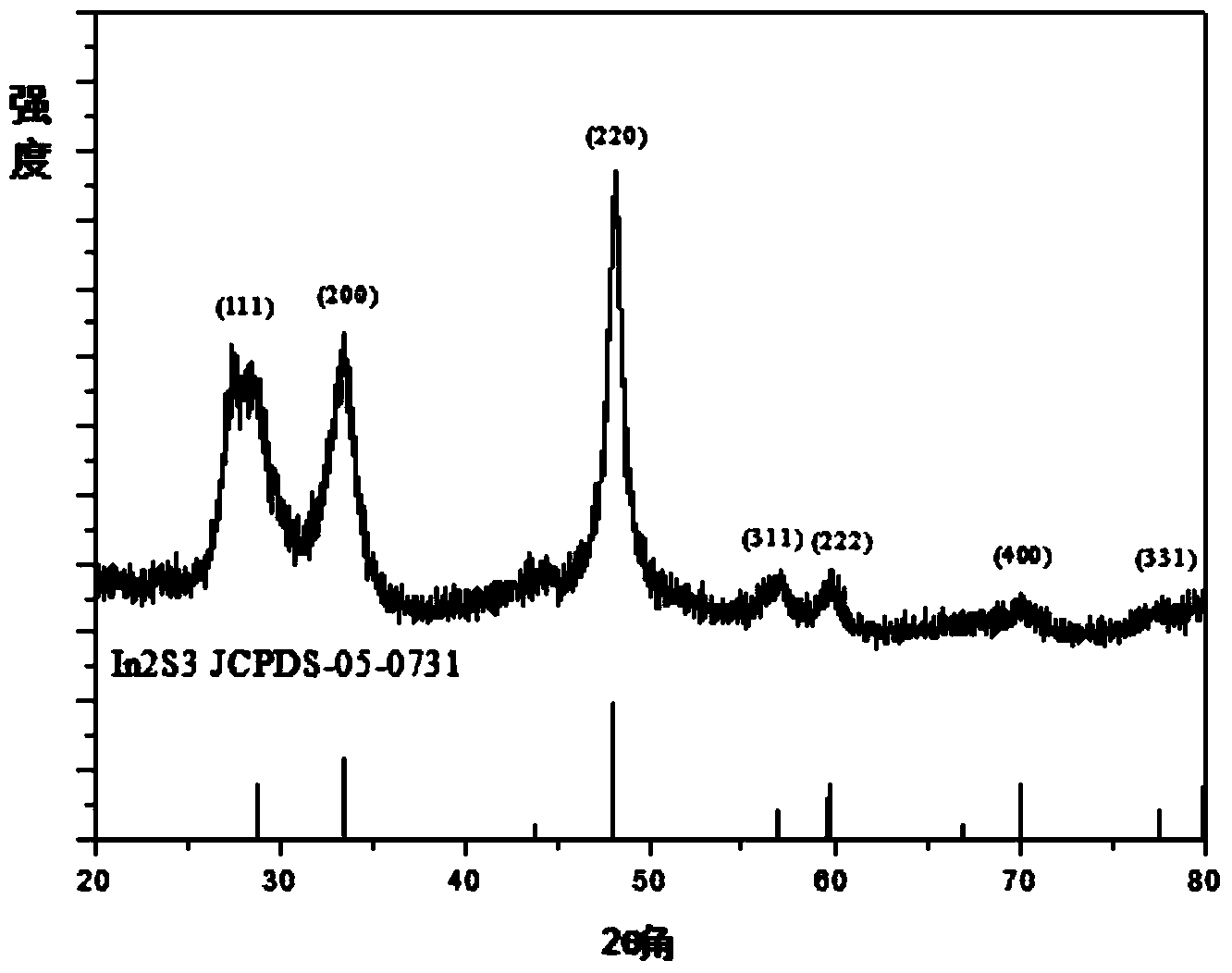

[0021] A kind of nanometer indium sulfide photocatalyst, chemical formula is shown as In 2 S 3 , which is a 3D spherical structure and the surface of the sphere is composed of nanosheets. This morphology feature makes it have a larger specific surface area and pore volume and generate more active sites.

[0022] The preparation method of the nano-indium sulfide photocatalyst is prepared by a hydrothermal method, and the steps are as follows:

[0023] 1) Dissolve 0.2737g indium chloride, 0.4525g L-cysteine and 0.056g sodium hydroxide into 55ml deionized water and stir vigorously for 15min to obtain a mixed solution;

[0024] 2) Move the above mixed solution into a hydrothermal kettle, and then place the hydrothermal kettle in an oven for constant temperature crystallization at 140°C for 16 hours. After the constant temperature reaction is completed, take out the hydrothermal kettle, and discard the supernatant after cooling to room temperature. collect sediment;

[0025] 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap