Motorboat coating production line

A coating production line and motorboat technology, applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems of single product color and low production efficiency, and achieve clear color separation, convenient operation and consistency good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

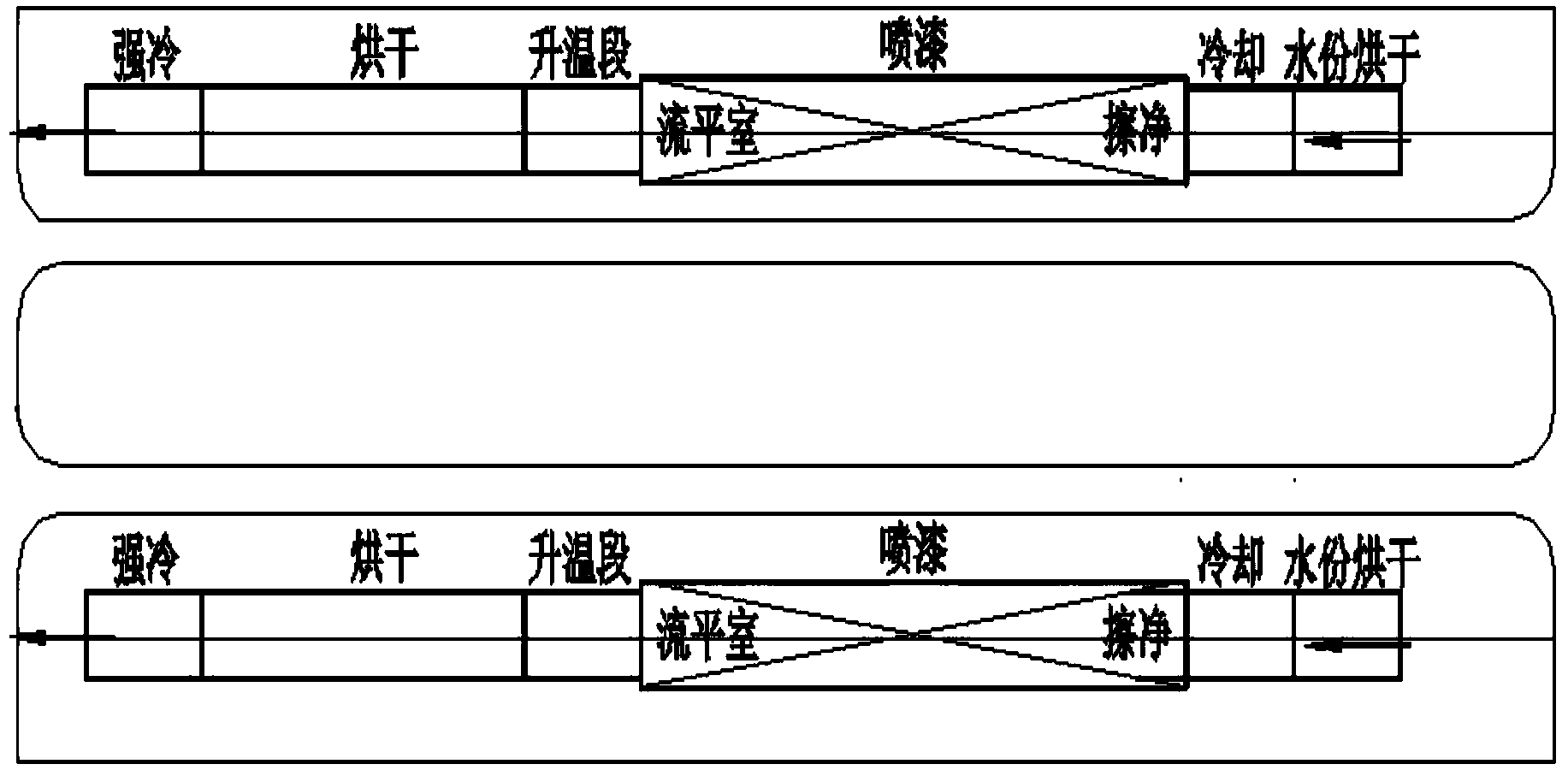

[0042] See attached figure 1 , a kind of motorboat coating production line provided by the present invention comprises:

[0043] The transport trolley used to carry the motorboat, the ground transmission device for fixing and carrying the transport trolley, the manual work area and the automatic work area; the transport trolley includes: frame, rollers, connectors; the frame is a hollow cuboid structure; the motor boat Placed on the frame; the rollers are set at the bottom side of the frame; the connecting piece is fixedly connected to the front end of the bottom of the frame; the ground transmission device includes: a fixing piece, a conveyor chain and a conveyor chain control module; the fixing piece and the transport trolley The connecting piece cooperates to fix the transport trolley on the conveyor chain of the ground conveyor; the conveyor chain control module is used to control the start, stop and running speed of the conveyor chain; the ground conveyor is set in the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com