Steamship with backup floating assisting air bags

A technology for airbags and ships, which is used in ship safety, ships, transportation and packaging, etc. It can solve the problems of no backup flotation airbag, tilting of the hull, capsize, etc., to achieve valuable escape and rescue time, and slow down the sinking speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

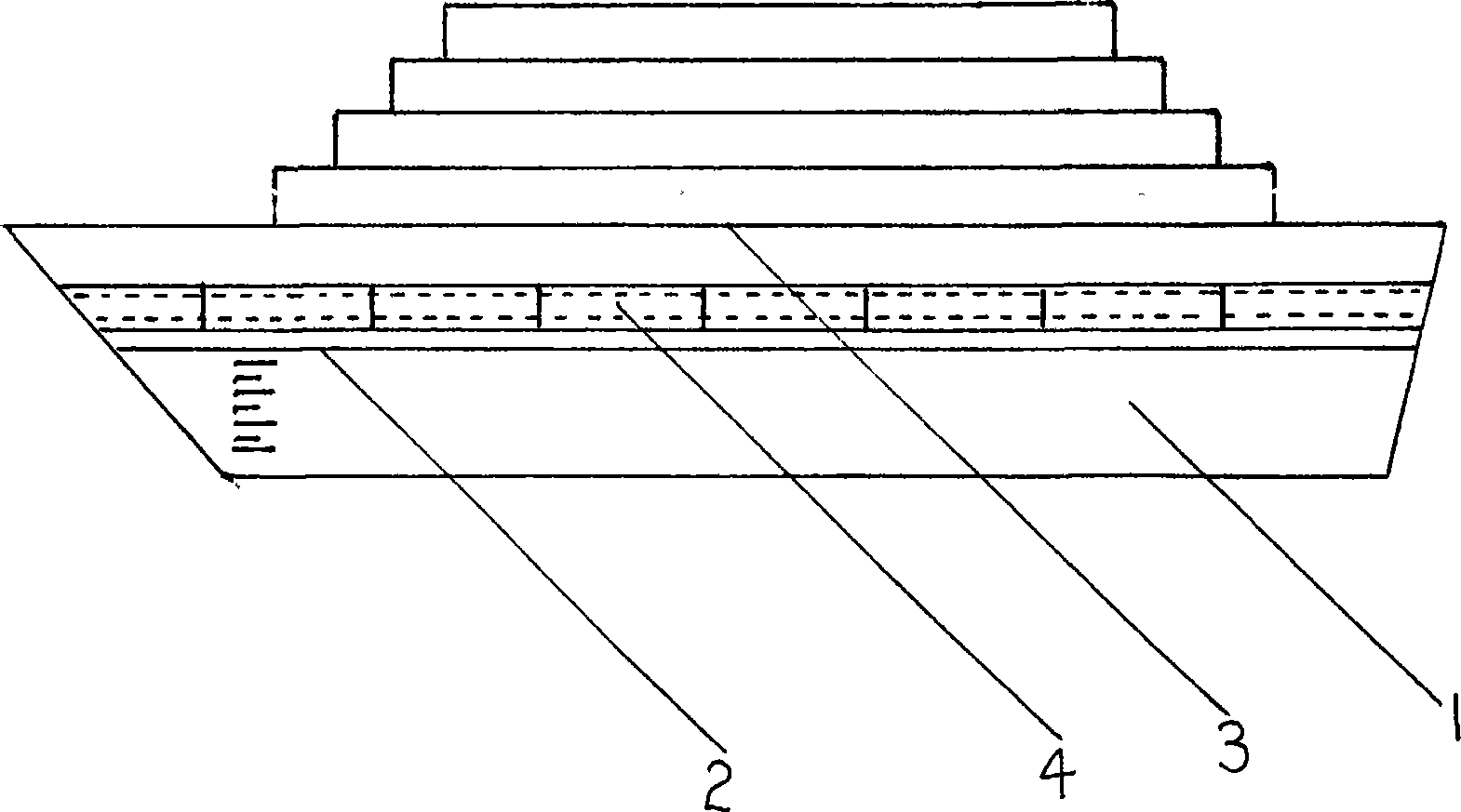

[0008] The ship with spare buoyancy-supporting airbags of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The ship is above the waterline and around the ship's rails below the deck.

[0009] Specific working conditions: When the ship hits a rock, collides, or sinks when the cabin is flooded, the crew can quickly open the air flushing electromagnetic valve on the inclined and sinking side, and the compressed air in the compressed air tank inside the ship enters the "U" shaped groove on the side of the ship. The spare inner airbag inside, the airbag will automatically push open the groove cover there, and the airbag will be quickly released from the groove to generate buoyancy. The rope pulls the side of the ship in the groove to prevent it from tilting and continuing to sink. When the entire cabin of the ship is flooded and sinks as a whole, all the spare buoyancy-supporting airbags around the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com