Detachable thermal insulation box

A thermal insulation and packaging technology, applied in thermal insulation containers, packaging, transportation and packaging, etc., can solve the problems of no easy recycling solution, increase the cost of repeated use, low production efficiency, etc., and achieve easy industrial production line production, The effect of saving transportation and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

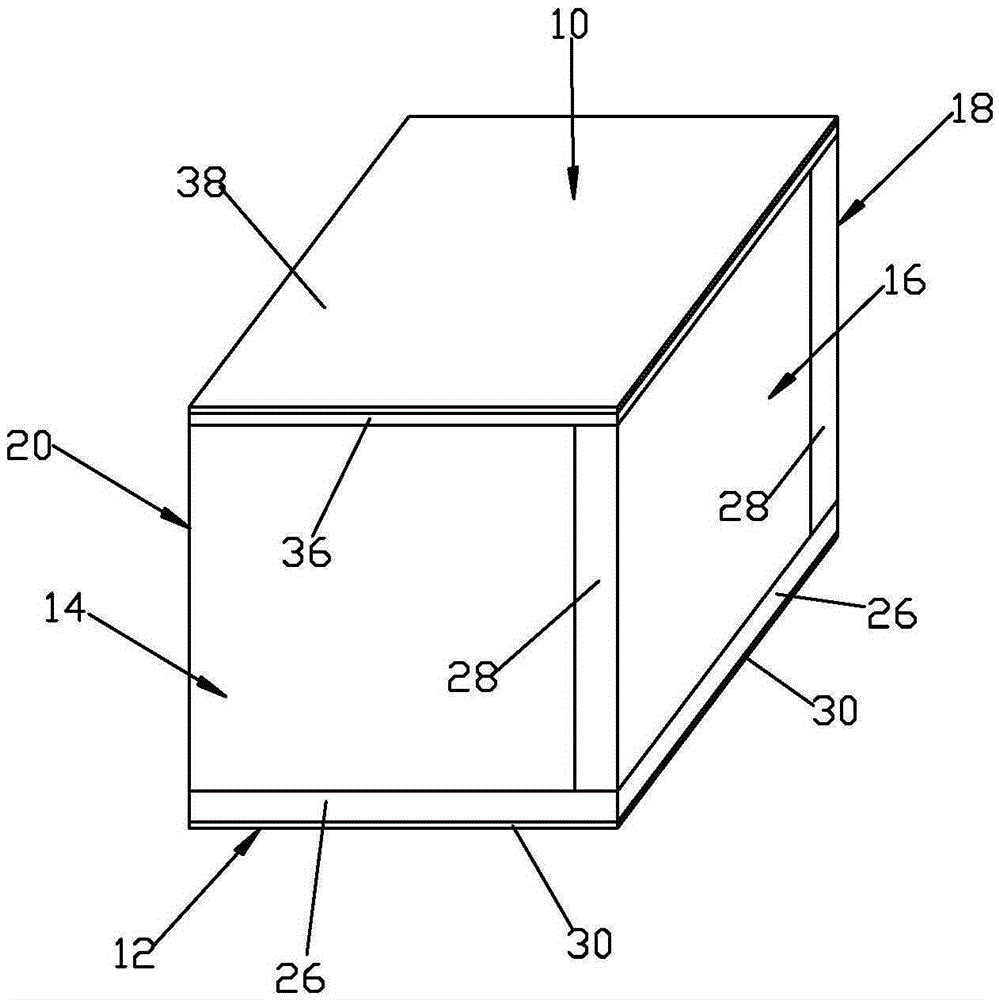

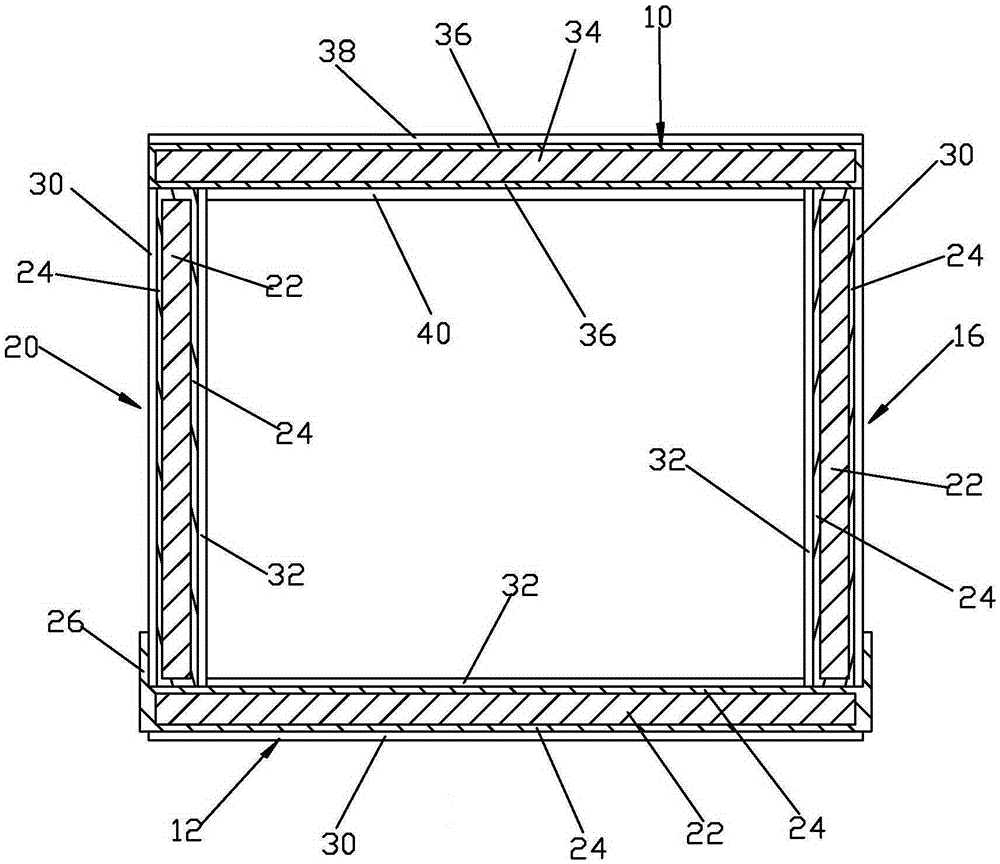

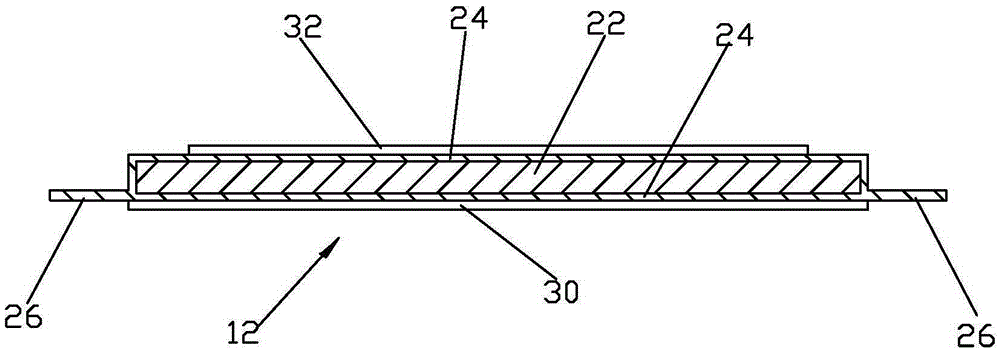

[0036] Please check Figure 1 to Figure 5 , the detachable thermal insulation box includes a box body and a box cover 10 which can be adapted to cover the box body. The box body includes a plurality of heat insulation panel units, and the plurality of heat insulation panel units can be connected together to form the box body. Each insulation board unit includes a heat insulation board 22 and a cladding layer 24 covering the outside of the heat insulation board 22. In a preferred solution, the heat insulation board is a vacuum insulation panel (VIP), and the cladding layer is polyurethane. However, it is not limited to this, and other high-insulation materials can also be used for the heat-insulation board as required, and other materials can also be used for the cladding layer. The cladding layer 24 has connecting ear portions 26, 28 protruding from the heat insulating plate 22; the plurality of heat insulating plate units are arranged into a box body, and the connecting ear ...

Embodiment 2

[0042] It differs from Embodiment 1 in that: Please refer to Image 6The peripheral edge of the cladding layer 36 in the box cover 10 has a folded edge portion 42 protruding from the heat insulating plate 34 and is laminated on the upper side of the box cover 10 .

Embodiment 3

[0044] It differs from Embodiment 1 in that it also includes an outer box frame, the box body is adapted to be installed in the outer box frame, and the attachment of the plurality of heat insulation board units is positioned through the outer box frame, then the connecting ear The lamination with the thermal insulation panel unit can be done without bonding, just abutting, or without exterior trim. The outer box frame is, for example, a carton, a plastic basket, a turnover basket and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com