Head wheel mechanism for chain conveyor of automated conveyor line

A technology of chain conveyors and conveyor lines, which is applied in the direction of conveyors, transportation, and packaging. It can solve the problems of undurable, uneconomical, and small loads, and achieve the effects of long service life, high safety, and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

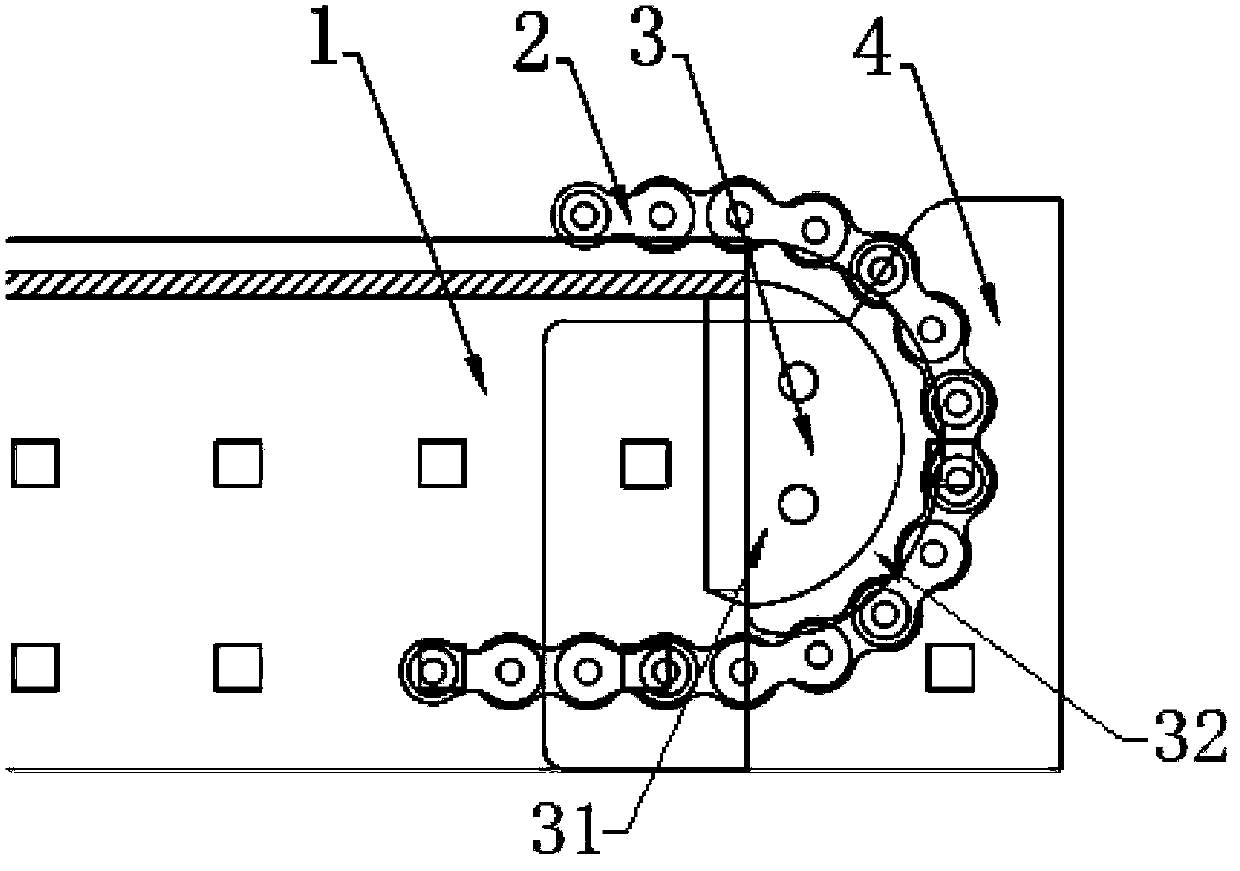

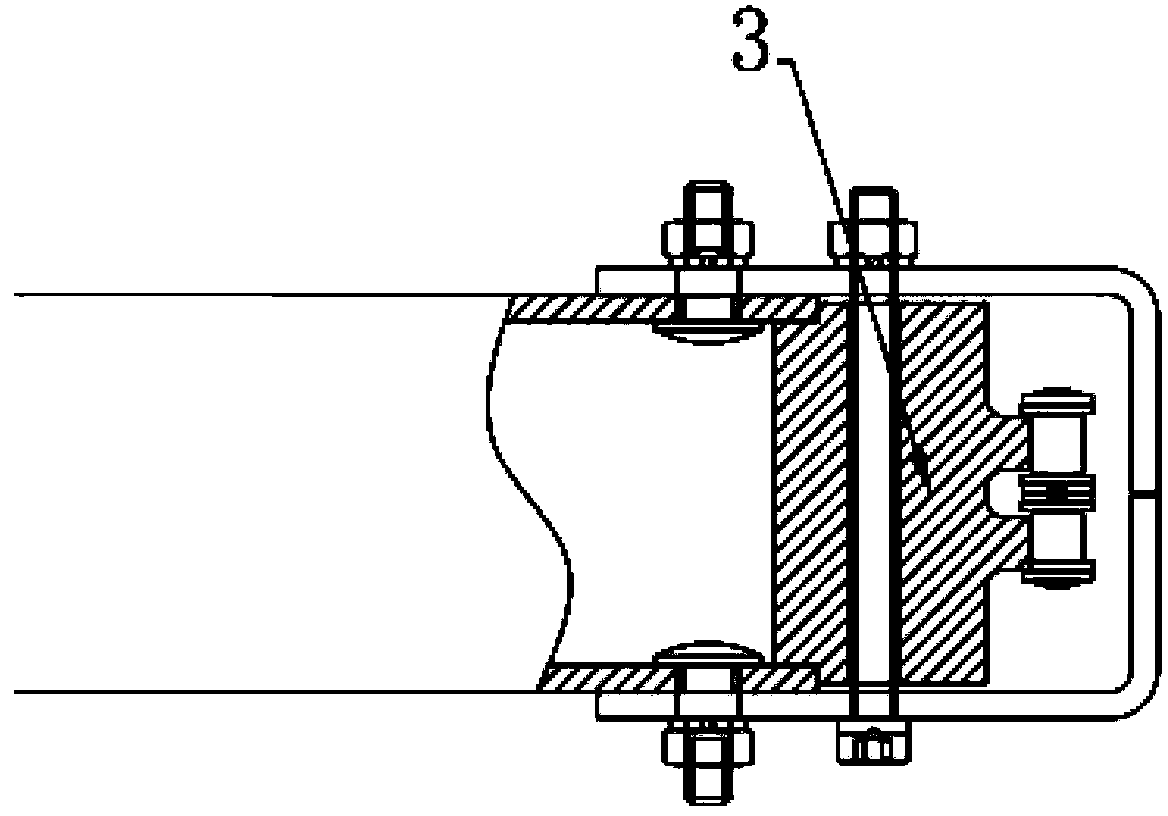

[0018] Such as Figure 1-Figure 2 As shown, a head wheel mechanism for a chain conveyor in an automated conveyor line, the chain conveyor includes a fuselage 1 and a chain 2 arranged on the fuselage 1, and the head wheel mechanism includes a head wheel body 3 and a support frame 4, the support frame 4 is set on the fuselage 1, the head wheel body 3 is fixed on the support frame 4 and the fuselage 1 by fasteners, the chain 2 and the head wheel The main body 3 is connected and surrounds the head wheel main body 3 . The head wheel mechanism is made of polymer engineering plastics. The material is impact-resistant, wear-resistant, low-noise, long-life, does not require refueling and maintenance, and has high stability; the particularity of the material reduces its own weight and facilitates the installation and maintenance of the fuselage.

[0019] The head wheel body 3 includes a stepped base 31 and an arc-shaped track 32, the arc-shaped track 32 is arranged on the side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com