Aeolian sand paste-like filling material for coal mine

A filling material and aeolian sand technology, which is applied in the field of aeolian sand-like paste coal mine filling materials, can solve the problems of barren land, poor vegetation conditions, shortage of water resources, etc., and achieves low operating energy consumption, reduced operating energy consumption, Anti-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Filling material mix ratio composition:

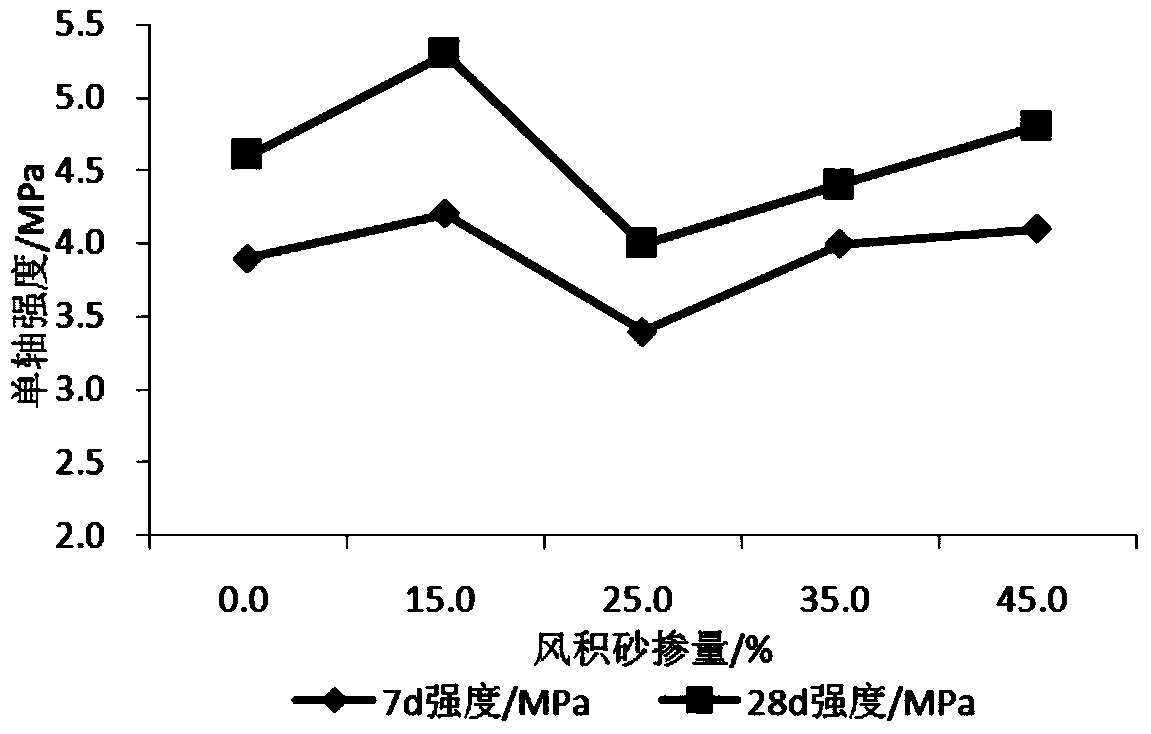

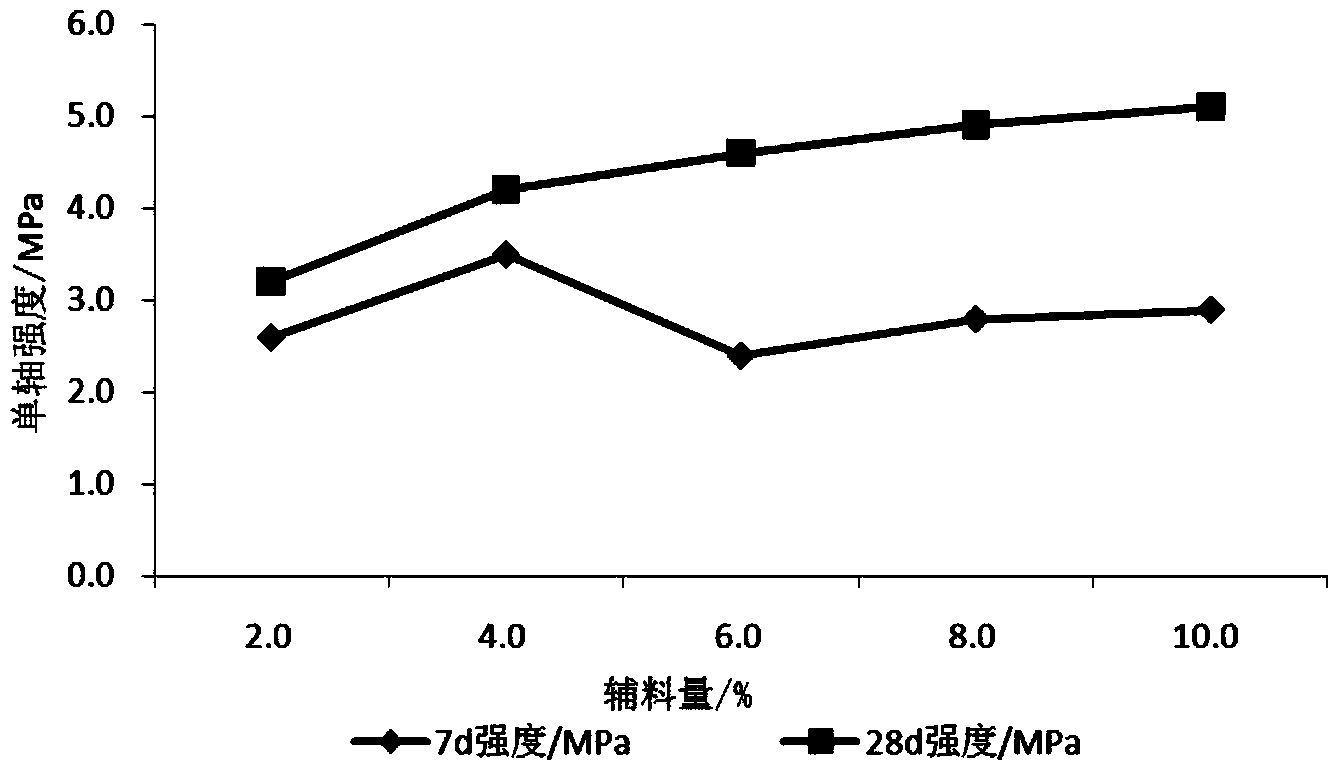

[0025] 1. Experimental results of different aeolian sand content

[0026] Filling material The main components of the aeolian sand-like paste filling material are: aeolian sand, fly ash, cement, auxiliary materials and water. The experimental plan is based on the mass ratio, and the ratio of fly ash, cement, auxiliary materials and water is 1:0.06. :0.14:1.1 The mass ratio remains unchanged, and the amount of aeolian sand (that is, the proportion of aeolian sand to the total weight of the filling material) is: 0% (that is, no aeolian sand is added), 15%, 25%, and 35% % and 45% were tested in the laboratory. Wherein, the composition of auxiliary material is unslaked lime, gypsum and admixture, three kinds of components are calculated by weight percentage, 82% quicklime, 8% gypsum, 10% admixture (admixture is specifically calcium sulfoaluminate and aluminum powder paste, sulfoaluminate The weight ratio of calcium and aluminum po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Average intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com