Preparation of high-purity l-tert-leucine by biological method

A technology of tertiary leucine and leucine dehydrogenase, applied in the field of biosynthetic preparation of L-tertiary leucine, can solve the problems of high price and high cost, and achieve low cost, low pollution and high selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

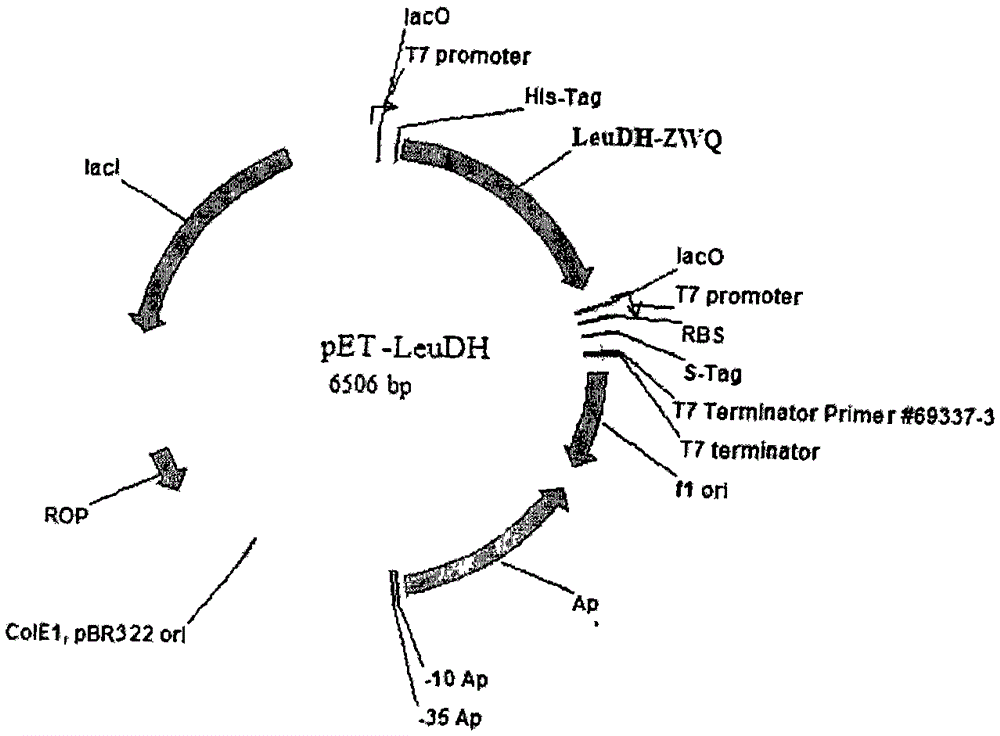

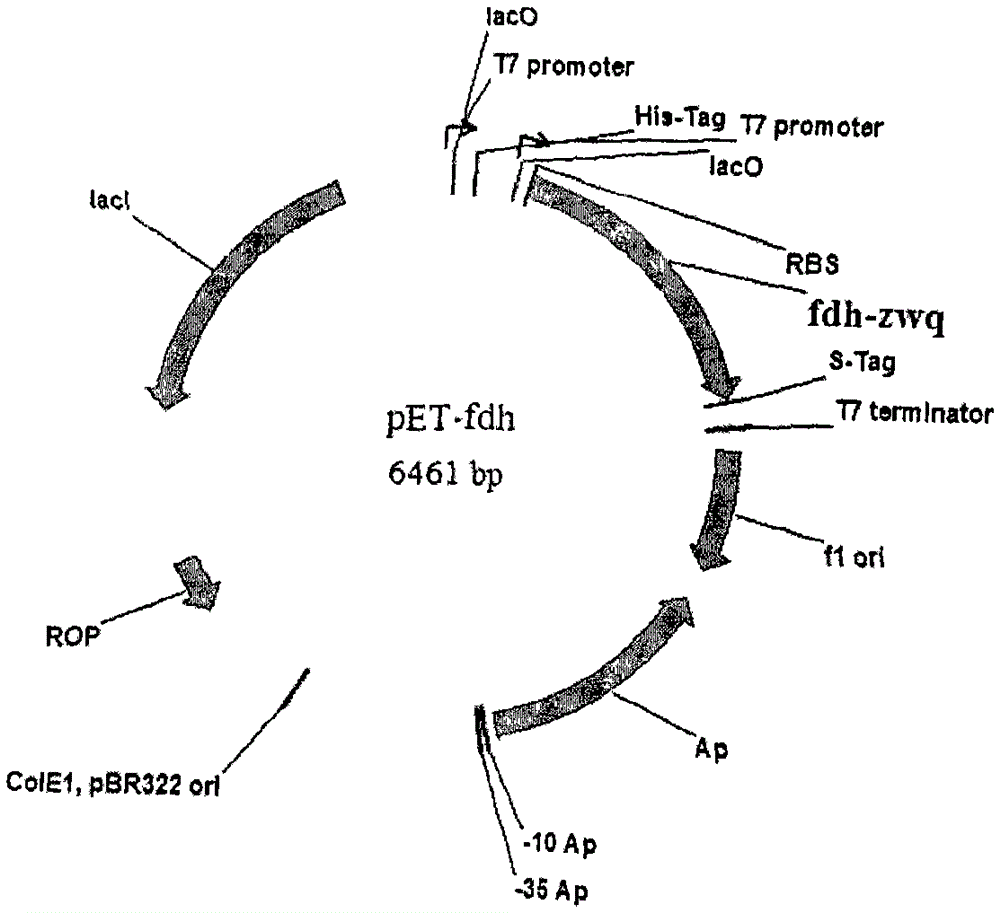

[0026] Embodiment 1, the construction of two kinds of recombinant bacteria containing leucine dehydrogenase gene and formate dehydrogenase gene

[0027] Genomic DNA was extracted from Bacillus cereus and Candida boidinii respectively, and the target gene fragments of fdh (formate dehydrogenase) and LeuDH (leucine dehydrogenase) were obtained by PCR method respectively. Gene fragments; then, express the fdh target gene and LeuDH target gene through the plasmid pETDuet-1. For detailed operation methods, see Organic Process Research & Development, 2006, 10, 666-669.

Embodiment 2

[0028] Embodiment 2, self-induced fermentation culture of genetically engineered bacteria (two kinds of recombinant bacteria culture methods are the same). Add 100 μl of genetically engineered bacteria seed solution into 10 ml LB medium containing 100 μg / ml kanamycin, and cultivate overnight at 37° C. and 200 rpm. Take 400 μl of the bacterial solution in the logarithmic growth phase and insert it into 40 ml of the following medium containing 100 μg / ml kanamycin, and incubate at 37° C., 200 rpm for 12 hours. The medium composition is: 1% tryptone, 0.3% yeast extract, 25mM Na 2 HPO 4 , 25mM KH 2 PO 4 , 50mM NH 4 Cl, 5mM Na 2 SO 4 , 2mM MgSO 4 , 1.0% glycerol, 0.05% glucose, 0.25% lactose, 100 μM FeCl 3 .

Embodiment 3

[0029] Example 3, preparation of recombinant cell suspension: the fermented broth was centrifuged (10000g, 5 minutes, 4°C) to obtain crude bacteria, washed and suspended with pH6.0-7.0 phosphate buffer, used for the following experiments or stored in- 20°C for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com