7000 series aluminum alloy member excellent in stress corrosion cracking resistance and method for manufacturing the same

一种铝合金构件、耐应力腐蚀的技术,应用在耐应力腐蚀裂纹性优异的7000系铝合金构件及其制造领域,能够解决裂纹性降低、挤压材料强度降低、成形性提高等问题,达到改善耐应力腐蚀裂纹性、减少拉伸残余应力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the 7000-series aluminum alloy member of the present invention and its manufacturing method will be specifically described.

[0033] (composition of aluminum alloy)

[0034] First, the composition of the 7000-series aluminum alloy of the present invention will be described. However, its composition itself is known as a 7000-series aluminum alloy.

[0035] Zn: 3.0 to 9.5% by mass

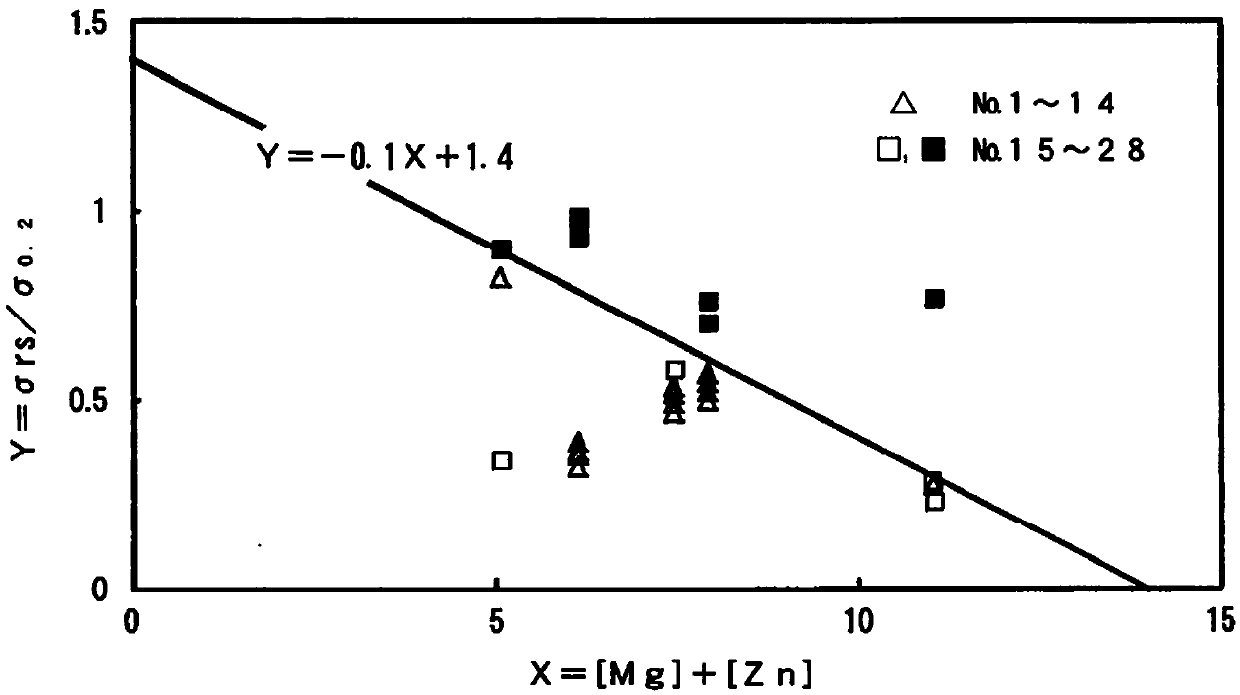

[0036] Mg: 0.4 to 2.5% by mass

[0037] Zn and Mg form MgZn as an intermetallic compound 2 , is an element that increases the strength of the 7000-series aluminum alloy. When the Zn content is less than 3.0% by mass or the Mg content is less than 0.4% by mass, a yield strength of 200 MPa or more required as a practical material cannot be obtained. On the other hand, if the Zn content exceeds 9.5% by mass or the Mg content exceeds 2.5% by mass, even if a predetermined regression process is performed on the hollow extruded material before pipe expansion, when pipe expansion is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com