Combination and flat-lamination construction method

A construction method and flat sticking technology, applied in the processing of building materials, building components, construction, etc., to achieve the effect of improving work efficiency and installation accuracy, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

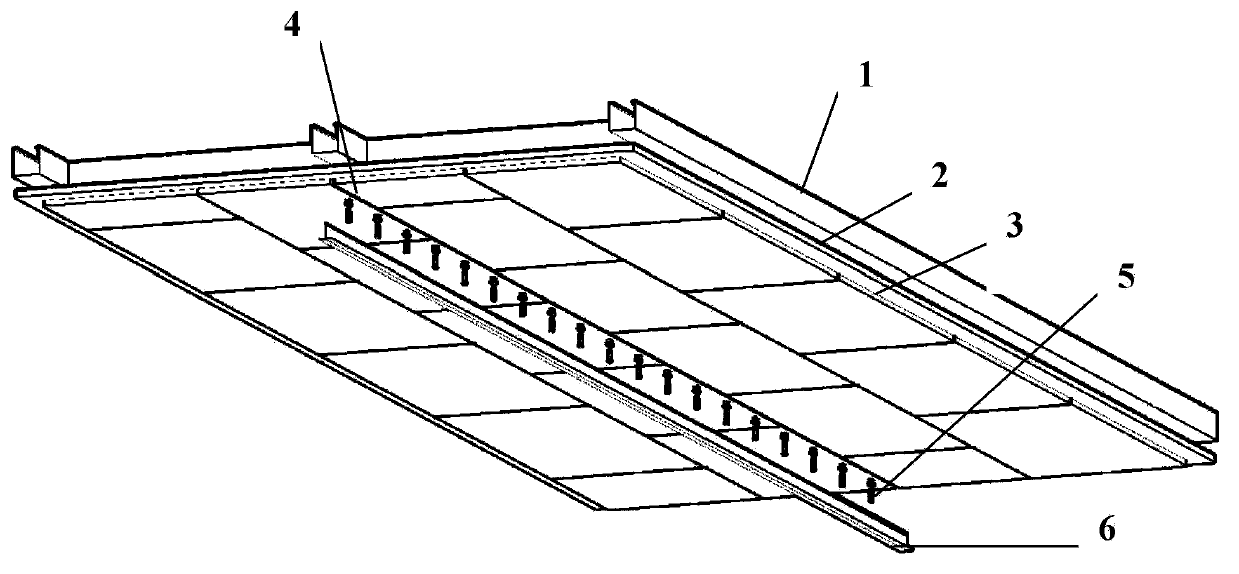

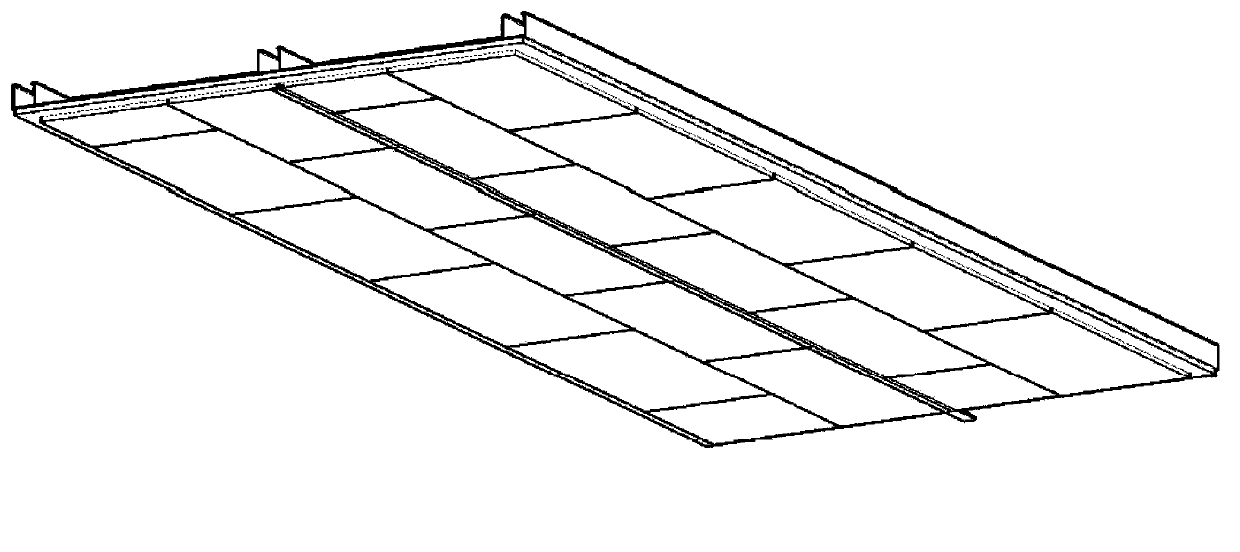

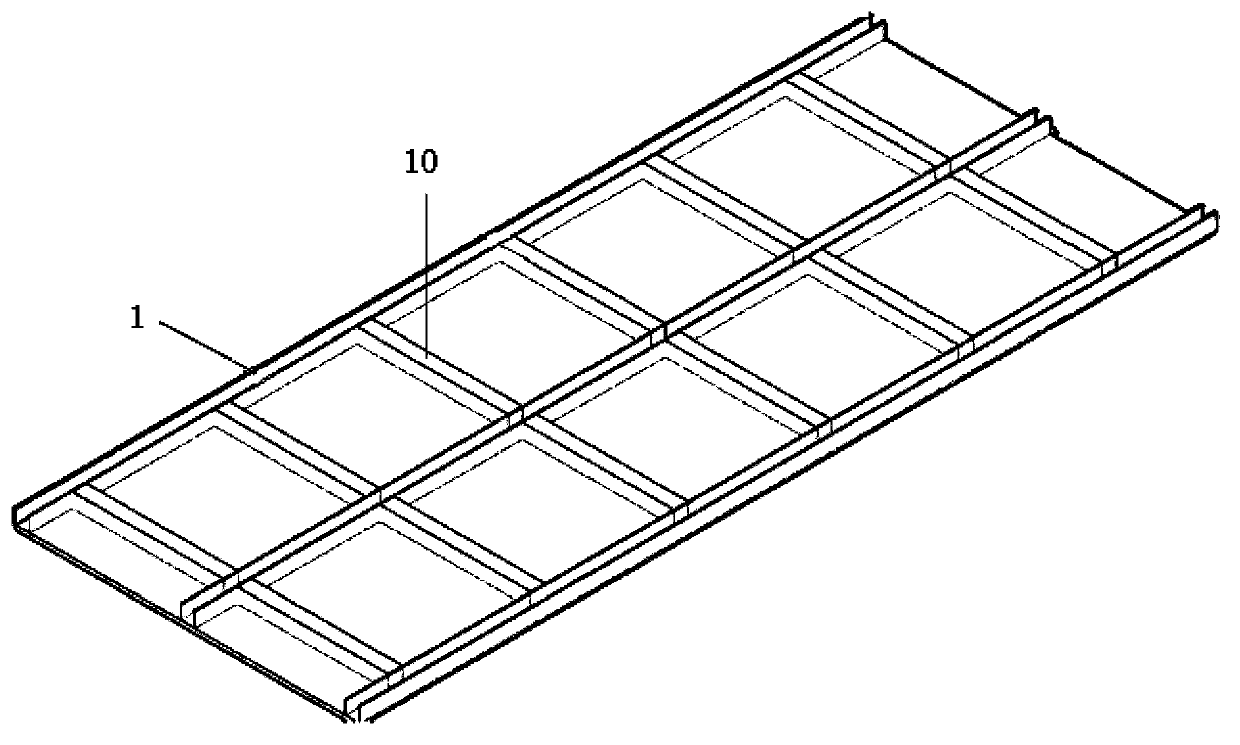

[0025] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

[0026] According to the composite flat sticking construction method of gypsum board and mineral wool decorative sound-absorbing board of the present invention, comprises the following steps:

[0027] (1) Fix the gypsum board 2 on the work platform, draw the installation line of the mineral wool decorative sound-absorbing board 3 on the gypsum board 2, apply glue to the back of the mineral wool decorative sound-absorbing board 3, and stick it on the gypsum board 2, Preferably, an air nail gun can be further used for reinforcement to more firmly fix the mineral wool decorative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com